Introduction to Direct heating annealing furnace, introduction to Forging furnace advantages and characteristics

Direct heating annealing furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,features include Easy to control, Stable and reliable, Strong adaptability, Easy to maintain and Easy to control,it is widely used inlight industry,heat treatment,metallurgy,shipping,material and other industries,be of high quality,low in price。

1、Brief introduction of Direct heating annealing furnace

Direct heating annealing furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,the principle is simple.Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,Widely used in Metal forging heating, Metal tempering, Metal forging heating, Metal heat treatment and Energy conservation and environmental protection。

Direct heating annealing furnace

2、Advantages of Direct heating annealing furnace principle

Direct heating annealing furnacein the course of work,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,the main structure includes Radiation chamber, combustor, furnace chamber, Radiation chamber, combustor and so on,It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、Usually equipped with intelligent control system, it can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.、Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials.、It can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.,it has the functions of quench, Forging heating, temper, normalizing and heat treatment,was developed and designed by One-combustion energy saving。

Direct heating annealing furnace

3、Introduction of Direct heating annealing furnace characteristics

Direct heating annealing furnace has the following characteristics

- Easy to maintain

- Easy to control

- Strong adaptability

- Stable and reliable

- Easy to control

The structural design of the Direct heating annealing furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The combustion system and ventilation system of the Direct heating annealing furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

The Direct heating annealing furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

The Direct heating annealing furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The combustion system and ventilation system of the Direct heating annealing furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

Direct heating annealing furnace

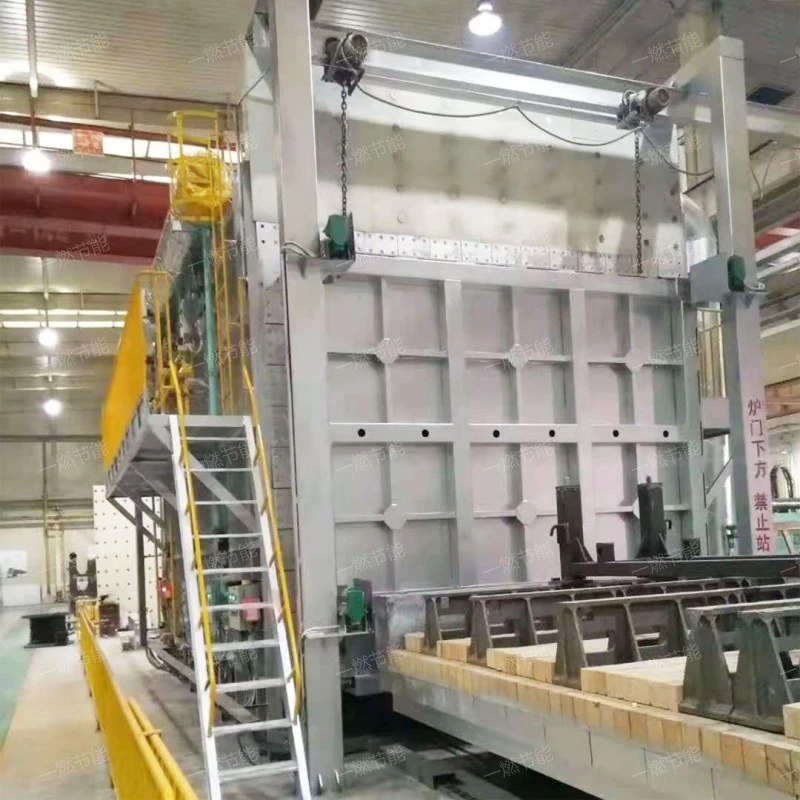

4、Direct heating annealing furnace HD real shot

On-site aerial photography of Direct heating annealing furnace。

Direct heating annealing furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd it has the characteristics of energy-efficient, energy saving and environmental protection, Stable and reliable, energy saving and environmental protection and Easy to maintain。

5、Direct heating annealing furnace function

Direct heating annealing furnacemultifunctional, with functions such as hardening and tempering, heat treatment, anneal, normalizing and quench,the main features are Easy to control, Strong adaptability, energy-efficient, energy saving and environmental protection and Stable and reliable,It is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,is a kind of high quality and low price Direct heating annealing furnace,customizable。

Direct heating annealing furnace

6、Company preferential activities

Direct heating annealing furnace is a new type of Forging furnace introduced by One-combustion energy saving manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for war industry and other industries. Now consult Direct heating annealing furnace, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

One-combustion energy saving

Direct heating annealing furnacethe main structure includes furnace chamber, ventilation system, convection chamber, ventilation system, recovery of waste heat and so on,This Direct heating annealing furnaceThe overall structural design is relatively simple and compact.,it can be used in light industry, pharmacy, Machinery manufacturing, aerospace, Household necessities and other industries。

Related recommendation

-

Introduction to Fully automatic multi well heating furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Electric heating and tempering furnace and Trolley resistance furnace working principle

2025-5-27 -

Introduction to Steel plant denitrification equipment and SCR denitration structure principle

2025-5-27 -

What is a Quenched and tempered well type quenching furnace? How much is the price of the forging furnace?

2025-5-27 -

What is a Well type isothermal quenching furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

Introduction to High temperature rapid quenching heating furnace and heating furnace structure principle

2025-5-27 -

Introduction to Rotary annealing industrial furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

Introduction to Nickel based alloy heating furnace and heating furnace working principle

2025-5-27 -

What is a Heat treatment well type heat treatment furnace? Introduction to the Working Principle of forging furnace

2025-5-27 -

What is a Strip heating furnace flue gas denitrification equipment? Introduction to the advantages, characteristics, and principles of the SCR flue gas denitrification

2025-5-27