What is a Forging heating furnace chamber type? Introduction to the advantages and characteristics of Forging furnace functions

Forging heating furnace chamber typeIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.。The following is to introduce the Forging heating furnace chamber type:

1、Brief introduction of Forging heating furnace chamber type

Forging heating furnace chamber typeIt is a forging heating device using gas as fuel.,it has the functions of Casting heating, heat treatment, normalizing, anneal and temper,is a Forging heating furnace chamber type,it can be used in Household necessities, automobile, metallurgy, surface treatment, Machinery manufacturing and other industries,has been favored by more and more customers.。

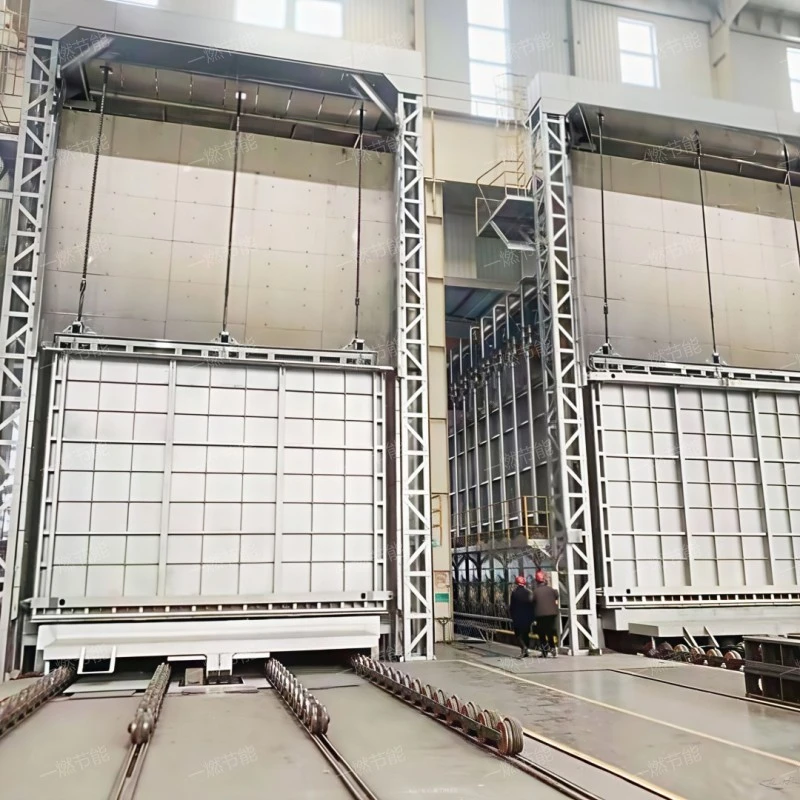

Forging heating furnace chamber type

2、Forging heating furnace chamber type structure

The Forging heating furnace chamber type structure is introduced as follows:

- furnace chamber

- ventilation system

- convection chamber

- furnace chamber

- ventilation system

A space for holding metallic materials for heating.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

A space for holding metallic materials for heating.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Forging heating furnace chamber type

3、Forging heating furnace chamber type function

Forging heating furnace chamber typemultifunctional, with functions such as quench, hardening and tempering, Forging heating, Casting heating and temper。

Forging heating furnace chamber type

4、Forging heating furnace chamber type HD picture

Haide Forging heating furnace chamber type manufacturing factory。

Forging heating furnace chamber type

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、How much is the Forging heating furnace chamber type?

The Forging heating furnace chamber type price is introduced as follows:

- technology content

- select a qualified person

- region

- Configuration difference

- Manufacturer scale

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

The quality of material selection is one of the main factors that directly affect the Forging heating furnace chamber type. If the quality of material selection is better, the price may be more expensive. Therefore, customers must first understand the quality of material selection before purchasing products, and then compare whether the quality and price match.

The price of Forging heating furnace chamber type in Jinan, Shandong province is much lower than that in other regions, and One-combustion energy saving is a large manufacturer not only pays attention to the quality of products, but also pays more attention to customer satisfaction, and always adopts the marketing strategy of small profits but quick turnover to make the Forging heating furnace chamber type price positioning more reasonable, low-cost and economical.

Usually, the quotation of Forging heating furnace chamber type changes with its configuration, but the quotation is different according to the different needs of customers and different product configurations.

There are many manufacturers of products in Shandong(Province), and the strength, technology and after-sales of each manufacturer are different, so the quotation for Forging heating furnace chamber type is naturally different.

Forging heating furnace chamber type

6、One-combustion energy saving company service

With intimate service, hard quality and advanced technology, the Forging heating furnace chamber type produced by One-combustion energy saving are not only guaranteed in quality but also affordable. One-combustion energy saving is always waiting for everyone's arrival.。

One-combustion energy saving

Forging heating furnace chamber typeThe overall structural design is relatively simple,it is mainly composed of combustor, convection chamber, furnace chamber, ventilation system and Radiation chamber,The use of clean and environmentally friendly natural gas as fuel effectively avoids the adverse effects of chemical reactions between impurities such as coal-fired furnaces and forgings during heating. At the same time, natural gas has high calorific value and high combustion temperature, and the combustion temperature can be further increased by preheating air and fuel. In addition, the gas forging heating furnace also has good heat loss control ability and intelligent control system, which can accurately adjust the ratio of air to natural gas, ensure full combustion of natural gas, and reduce mechanical incomplete combustion and chemical incomplete combustion.、Suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、Natural gas is used as a heat source, resulting in less waste gas and smoke after combustion, and less pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.,it is widely used in petroleum, pharmacy, chemical industry, Machinery manufacturing and petroleum。

Related recommendation

-

What is a Spheroidization annealing resistance furnace? Introduction to the advantages and characteristics of the Trolley resistance heating furnace

2025-5-27 -

Introduction to High temperature bright well quenching furnace and heating furnace structure principle

2025-5-27 -

What is a Electric heating trolley furnace? How much is the price of the Trolley electric heating furnace?

2025-5-27 -

What is a Dual car low-temperature heating furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

台车式双门炉

2023-06-25 -

Introduction to Pit type mold heating furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

What is a Fully automatic gas trolley furnace? forging furnace specifications, models, and parameters

2025-5-27 -

What is a Well type roasting furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

What is a SCR flue gas catalytic denitrification equipment? Introduction to the principle of SCR flue gas denitrification structure

2025-5-27 -

What is a Intelligent high-temperature industrial furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27