Introduction to Regenerative gas chamber heating furnace, advantages, characteristics and principles of heating furnace

Regenerative gas chamber heating furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,It can be used for Energy conservation and environmental protection, Metal tempering, Metal melting and casting, Improve production efficiency, Metal forging heating, Energy conservation and environmental protection and so on,multifunctional, with functions such as normalizing, hardening and tempering, anneal, normalizing and Forging heating,is a kind of high quality and low price Regenerative gas chamber heating furnace,has been favored by more and more customers.。The following is to introduce the Regenerative gas chamber heating furnace:

1、Brief introduction of Regenerative gas chamber heating furnace

Regenerative gas chamber heating furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,Adopting advanced combustion technology and control system can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.、It can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.、Suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.、Efficient combustion and waste heat recovery system can significantly reduce energy consumption, thus reducing operating costs.,the main structure includes furnace chamber, Radiation chamber, combustor, convection chamber, furnace chamber and so on,productThe overall structural design is relatively simple,customizable。

Regenerative gas chamber heating furnace

2、Regenerative gas chamber heating furnace use

The purpose of Regenerative gas chamber heating furnace is introduced as follows:

- Metal tempering

- Metal heat treatment

- Energy conservation and environmental protection

- Improve production efficiency

- Metal forging heating

By properly heating and cooling the metal material, the Regenerative gas chamber heating furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

In addition to forging heating, Regenerative gas chamber heating furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

The Regenerative gas chamber heating furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

The Regenerative gas chamber heating furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

The Regenerative gas chamber heating furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

Regenerative gas chamber heating furnace

3、Regenerative gas chamber heating furnace application

Regenerative gas chamber heating furnaces have the following purposes.

- Metal melting and casting

- Metal tempering

- Improve production efficiency

- Metal melting and casting

- Metal forging heating

Although it is mainly used for forging heating, some types of Regenerative gas chamber heating furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

By properly heating and cooling the metal material, the Regenerative gas chamber heating furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

The Regenerative gas chamber heating furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

Although it is mainly used for forging heating, some types of Regenerative gas chamber heating furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

The Regenerative gas chamber heating furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

Regenerative gas chamber heating furnace

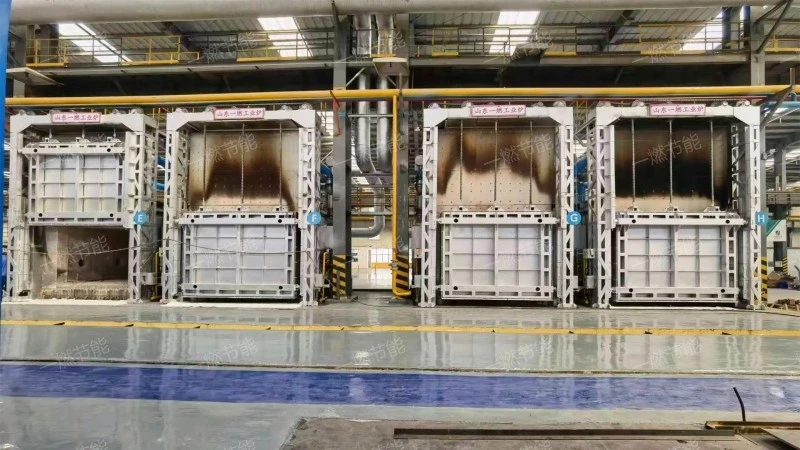

4、Regenerative gas chamber heating furnace customer scene picture

One-combustion energy saving Regenerative gas chamber heating furnacethe product looks beautiful., the picture is taken.。

Regenerative gas chamber heating furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Regenerative gas chamber heating furnace price consultation

The Regenerative gas chamber heating furnace price is introduced as follows:

- market demand

- Company size

- Model size

- Different regions

- Less intermediate links

This factor is directly related to the economic dynamics. When the economic dynamics are unstable, the relationship between supply and demand will be unbalanced, which will lead to a very large fluctuation in the price of Regenerative gas chamber heating furnace. Therefore, we should also be aware of the relationship between this factor and the price during the price setting process.

One-combustion energy saving's scale and strength are relatively strong, the technology and technology of products produced by manufacturers are relatively advanced, and there is less waste of resources in the process of manufacturing, and the price of products will be relatively low.

One-combustion energy saving Regenerative gas chamber heating furnace has various specifications and models, and the prices of different specifications and models are also different. The main difference lies in the different technologies used in the products and the different manufacturing costs. One-combustion energy saving Preferential activities will be launched regularly, and the whole set of purchasing Regenerative gas chamber heating furnace will enjoy greater discounts

One-combustion energy savingJinan, the transportation is convenient, and the corresponding cost of transporting Regenerative gas chamber heating furnace is low, which reduces the cost of selling Regenerative gas chamber heating furnace by manufacturers, and the price will also decrease.

What kind of sales methods manufacturers have has an intuitive impact on product prices. If it is a direct selling manufacturer, the manufacturer sells directly to customers, and there is no intermediate price difference, which can benefit customers to a greater extent.

Regenerative gas chamber heating furnace

6、company profile

One-combustion energy saving has many years of experience in Regenerative gas chamber heating furnace production, and is a professional Regenerative gas chamber heating furnace manufacturer. With favorable Regenerative gas chamber heating furnace price, stable product quality, rich product series and perfect after-sales service system, the company strives to become an advanced Regenerative gas chamber heating furnace manufacturer in Jinan, Shandong province.。

One-combustion energy saving

Regenerative gas chamber heating furnaceit is mainly composed of combustor, Radiation chamber, ventilation system, recovery of waste heat and convection chamber,the principle is simple.Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,the advantage is Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、Natural gas is used as a heat source, resulting in less waste gas and smoke after combustion, and less pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.、Adopting advanced combustion technology and materials, it has a long service life and low maintenance cost.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.。

Related recommendation

-

What is a Trolley forging heating furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to SCR denitration system, how much is the price of the SCR denitration system?

2025-5-27 -

What is a Continuous roll industrial furnace? Introduction to the advantages and characteristics of heating furnace functions

2025-5-27 -

Introduction to Explosion proof well tube furnace, how much is the price of the Forging furnace?

2025-5-27 -

What is a Tube type bright annealing furnace? heating furnace specifications, models, and parameters

2025-5-27 -

Introduction to Split type deep well furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

Introduction to Low temperature multi well heating furnace, heating furnace specifications, model parameters

2025-5-27 -

Introduction to Gas chamber furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Pressure vessel heating furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

What is a Roll type heat treatment furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27