What is a Multi tube annealing furnace? Introduction to the principle of forging furnace structure

Multi tube annealing furnaceIt is a forging heating device using gas as fuel.,Easy to maintain,energy-efficient,Strong adaptability,Easy to control,Easy to maintain,It has a wide range of uses, and is often used inEnergy conservation and environmental protection,Improve production efficiency,Metal tempering,Metal heat treatment,Metal forging heating and so on,at runtime,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,was developed and designed by One-combustion energy saving。

1、Brief introduction of Multi tube annealing furnace

Multi tube annealing furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,it can be used in electron, material, machinery, metallurgy, war industry and other industries,The structural design is more advanced and reasonable.,it is mainly composed of combustor, convection chamber, recovery of waste heat, ventilation system and convection chamber。

Multi tube annealing furnace

2、Multi tube annealing furnace principle

Multi tube annealing furnaceat the start of the operation,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,It has a wide range of uses, including Metal melting and casting, Metal melting and casting, Energy conservation and environmental protection, Metal heat treatment and Metal forging heating。

Multi tube annealing furnace

3、Introduction of Multi tube annealing furnace characteristics

Multi tube annealing furnace has the following characteristics

- Strong adaptability

- Easy to maintain

- Stable and reliable

- Stable and reliable

- Strong adaptability

The Multi tube annealing furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

The structural design of the Multi tube annealing furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The Multi tube annealing furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The Multi tube annealing furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The Multi tube annealing furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

Multi tube annealing furnace

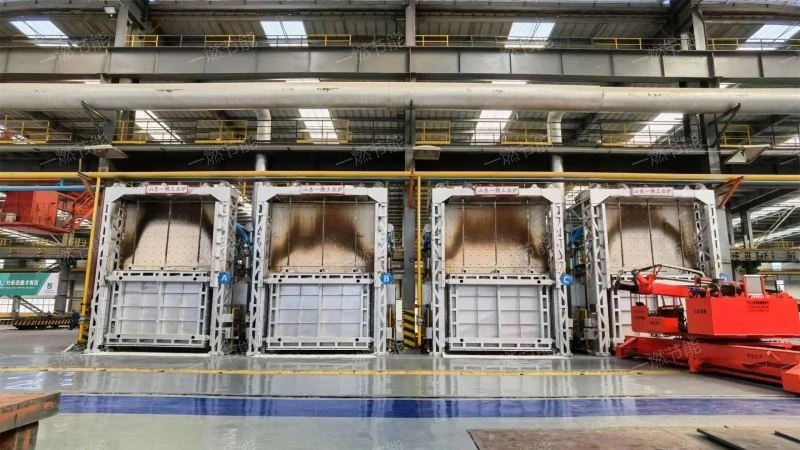

4、Multi tube annealing furnace picture

Its appearance design is exquisite and elegant. The following is a high-definition picture of the factory for One-combustion energy saving's customers to choose and buy. You can contact online customer service at any time, make an appointment to visit the factory and take a shuttle bus from One-combustion energy saving.。

Multi tube annealing furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Introduction of advantages of Multi tube annealing furnace

The advantages of Multi tube annealing furnace are as follows:

- Improve product quality

- Extend the service life of equipment

- Efficient combustion

- Multiple fuel options

- Rapid temperature rise

Because the Multi tube annealing furnace can realize uniform heating and precise control, it is helpful to improve the product quality and yield of metal materials.

The Multi tube annealing furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The Multi tube annealing furnace adopts advanced combustion technology and control system, which can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.

Although the Multi tube annealing furnace mainly uses natural gas as fuel, some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.

The Multi tube annealing furnace can heat the metal material to the required temperature in a short time, which improves the production efficiency.

Multi tube annealing furnace

6、Multi tube annealing furnace price consultation

The Multi tube annealing furnace price is introduced as follows:

- product configuration

- Self quality

- product function

- Model type

- market quotation

Configuration refers to the hardware composition of the product, which mainly includes material selection, parts selection, etc. The higher the overall configuration of the product, the higher the price of the Multi tube annealing furnace, which is beyond doubt. One-combustion energy saving makes every product with great care in the attitude of being highly responsible to customers, so the price of One-combustion energy saving Multi tube annealing furnace is reasonable for products with the same configuration.

The selling price of excellent quality products is also high, so customers should also consider the quality and price of products comprehensively in the process of purchasing products, so as to buy products with high cost performance.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The same product, different specifications and models, the performance of the product is different, therefore, manufacturers need different costs in producing and manufacturing products, so the prices of different specifications and models are different, and customers should give priority to suitability when purchasing.

Market change is one of the factors that affect the price range greatly. Market change is unstable, but there are certain rules to follow. Market change is caused by other factors, such as economic instability, competition among manufacturers and too big difference between supply and demand. These factors are the core reasons that cause the market to fluctuate greatly, and then it will have a bad impact on prices.

Multi tube annealing furnace

Multi tube annealing furnaceit has the functions of Forging heating, anneal, quench, anneal and heat treatment,it has the characteristics of Stable and reliable, Strong adaptability, energy-efficient, energy saving and environmental protection and Stable and reliable。

Related recommendation

-

What is a Dual car high-temperature annealing furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27 -

高精度高温台车电炉

2023-03-17 -

Introduction to Chain type roasting furnace and heating furnace working principle

2025-5-27 -

Introduction to Fully enclosed gas trolley furnace and forging furnace advantages and features

2025-5-27 -

Introduction to Low temperature catalytic reduction denitrification and SCR denitration working principle

2025-5-27 -

Introduction to Car positive furnace and Forging furnace working principle

2025-5-27 -

What is a Rotary heat treatment furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

What is a Fully automatic resistance furnace? Introduction to the principle of Trolley resistance heating furnace structure

2025-5-27 -

Introduction to Energy saving industrial resistance heating furnace, advantages, characteristics and principles of Trolley resistance heating furnace

2025-5-27 -

What is a Automatic top cylinder forging furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27