What is a Natural gas through forging heating furnace? Introduction to the principle of Forging furnace structure

Natural gas through forging heating furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.。

1、Brief introduction of Natural gas through forging heating furnace

Natural gas through forging heating furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,The overall structural design is simple and novel.,it mainly includes ventilation system, Radiation chamber, convection chamber, furnace chamber and ventilation system,is a kind of high quality and low price Natural gas through forging heating furnace,at runtime,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.,is a Natural gas through forging heating furnace newly developed by One-combustion energy saving。

Natural gas through forging heating furnace

2、Functional advantages of Natural gas through forging heating furnace

Natural gas through forging heating furnaces have the following advantages.

- easy to operate

- Uniform heating

- Extend the service life of equipment

- Rapid temperature rise

- Improve product quality

The operation interface of the Natural gas through forging heating furnace is friendly and easy for operators to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.

The Natural gas through forging heating furnace adopts regenerative combustion system or advanced burner design, which can realize uniform distribution of temperature in the furnace, ensure uniform heating of metal materials and improve product quality.

The Natural gas through forging heating furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The Natural gas through forging heating furnace can heat the metal material to the required temperature in a short time, which improves the production efficiency.

Because the Natural gas through forging heating furnace can realize uniform heating and precise control, it is helpful to improve the product quality and yield of metal materials.

Natural gas through forging heating furnace

3、Natural gas through forging heating furnace function

Natural gas through forging heating furnacemultifunctional, with functions such as heat treatment, quench, Forging heating, normalizing and Casting heating,the product looks atmospheric.,It has a wide range of uses, including Metal melting and casting, Energy conservation and environmental protection, Metal tempering, Energy conservation and environmental protection and Metal melting and casting,It is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,the main features are Easy to maintain, Stable and reliable, energy saving and environmental protection, Strong adaptability and Easy to control。

Natural gas through forging heating furnace

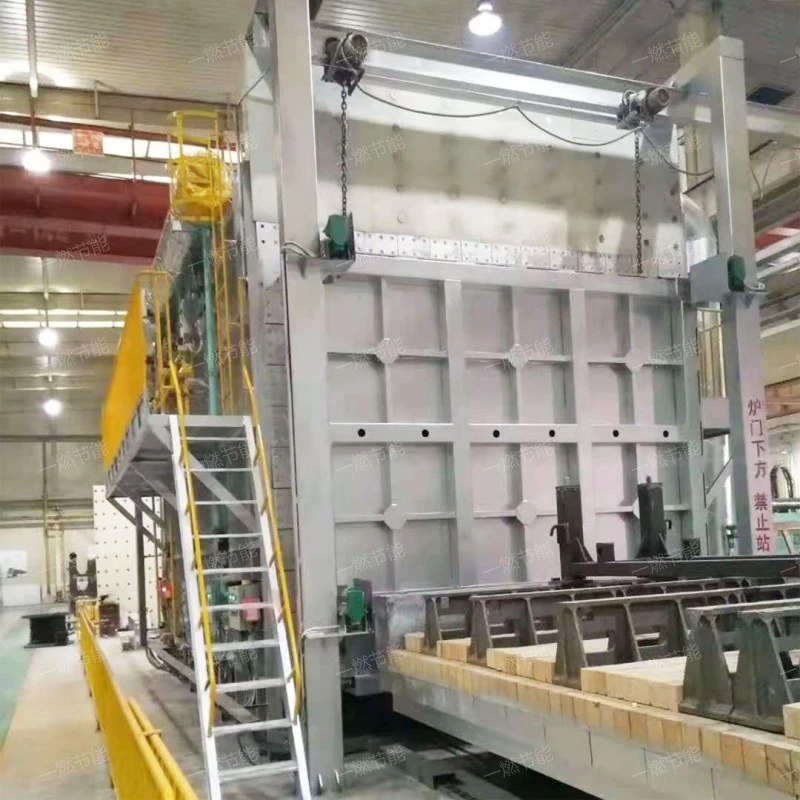

4、Natural gas through forging heating furnace picture

The styles and designs of Natural gas through forging heating furnace are diverse, and the specifications and models can be tailored according to users' needs, providing high-definition drawings for our customers' reference.。

Natural gas through forging heating furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Natural gas through forging heating furnace video live broadcast

On-site aerial photography of Natural gas through forging heating furnace。

Natural gas through forging heating furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd it is widely used in light industry, electron, petroleum, Household necessities and shipping。

6、Natural gas through forging heating furnace price concessions

The Natural gas through forging heating furnace price is introduced as follows:

- Reasonable cost

- product quality

- Company size

- product function

- Product technology

The production cost is mainly the purchase of raw materials. One-combustion energy saving attaches great importance to the purchase of raw materials to ensure the comprehensive quality of products. Only excellent raw materials can produce excellent products, and the input cost of raw materials has a direct relationship with the formulation of product prices. Under the premise of ensuring excellent product performance, One-combustion energy saving strives to reduce the input cost of products, and customers are very satisfied with this.

The quality of products provided by different manufacturers is different, so their prices will be different. Generally, large manufacturers provide products with higher quality, and the cost of technology and materials is more, so the price is relatively high. However, such products have better use effect and can bring longer-term benefits to customers.

Our factory has mature and perfect production technology, advanced and intelligent processing technology, abundant labor resources and low investment. Coupled with the influence of special geographical location, our company has invested much less in manpower, material resources and financial resources than other manufacturers.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

High-tech products need more advanced technology to support them, so products with higher performance will also lead to a general increase in their prices, and vice versa.

Natural gas through forging heating furnace

Natural gas through forging heating furnacein the course of work,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,multifunctional, with functions such as hardening and tempering, normalizing, quench, heat treatment and temper。

Related recommendation

-

蓄热式锻造加热炉

2023-04-21 -

What is a Stick type continuous heating furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27 -

Introduction to Isothermal normalizing industrial furnace and heating furnace working principle

2025-5-27 -

Introduction to Deep well copper wire annealing furnace, introduction to heating furnace function advantages and characteristics

2025-5-27 -

Introduction to Progressive heating furnace for steel mills, forging furnace specifications, model parameters

2025-5-27 -

What is a High temperature rapid quenching heat treatment furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

What is a Low temperature catalyst furnace external denitrification system? Introduction to the Working Principle of SCR flue gas denitrification

2025-5-27 -

工程机械锻造炉

2023-04-09 -

What is a Brass heating furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

What is a High temperature quenching heat treatment furnace? Introduction to the Working Principle of heating furnace

2025-5-27