Introduction to Energy saving trolley forging furnace, introduction to Forging furnace function advantages and characteristics

Energy saving trolley forging furnaceIt is a forging heating device using gas as fuel.,widely used in machinery, petroleum, war industry, automobile, metallurgy and other fields,is designed by One-combustion energy saving with advanced technology。The following is to introduce the Energy saving trolley forging furnace:

1、Brief introduction of Energy saving trolley forging furnace

Energy saving trolley forging furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.。

Energy saving trolley forging furnace

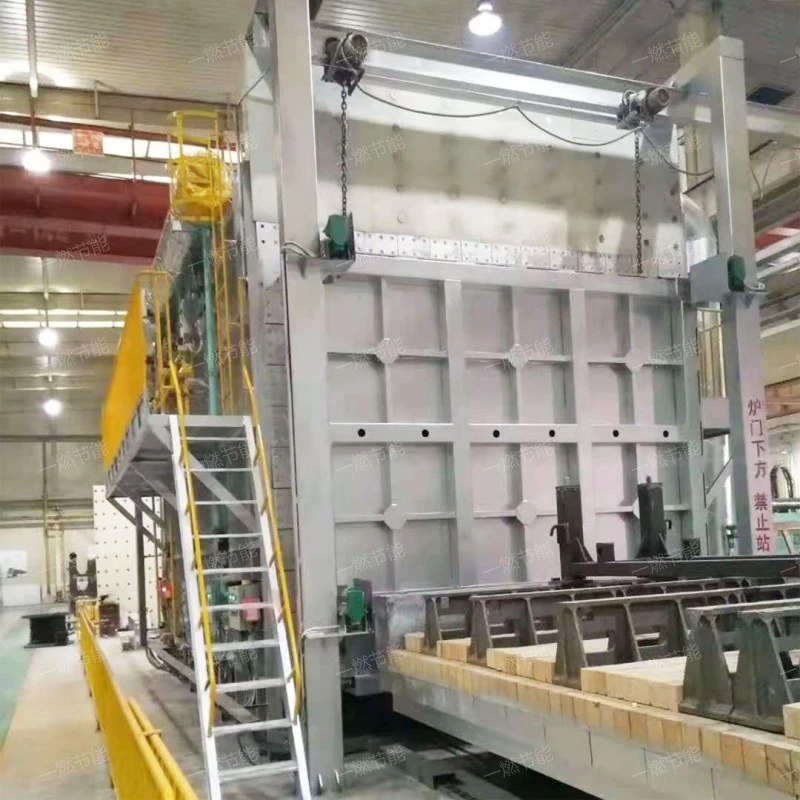

2、Energy saving trolley forging furnace field real shot

The following pictures can be used for reference by new and old customers.。

Energy saving trolley forging furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Energy saving trolley forging furnace field real shot

You can buy Energy saving trolley forging furnace according to your needs and show you product videos.。

Energy saving trolley forging furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.。

4、Structural characteristics of Energy saving trolley forging furnace

The Energy saving trolley forging furnace has the following structure

- Radiation chamber

- combustor

- ventilation system

- convection chamber

- Waste heat recovery system

The heat load of the main place for Energy saving trolley forging furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

The material is heated by convection heat transfer of high temperature flue gas discharged from the radiation chamber. Flue gas washes the tube wall of the furnace tube at a high speed to carry out effective convection heat transfer, and its heat load accounts for about 20%-30% of the whole furnace. The convection chamber is generally arranged above the radiation chamber, and some are placed on the ground alone. In order to improve the heat transfer effect, nail head tubes or finned tubes are often used in furnace tubes.

Used to recover the exhaust heat of the heating furnace. There are two kinds of recovery methods, one is to recover by preheating combustion air, so that the recovered heat can return to the furnace again; The other is to use another recovery system to recover heat. The former is called air preheating mode, and the latter is usually called waste heat boiler mode.

Energy saving trolley forging furnace

5、Working principle of Energy saving trolley forging furnace

Energy saving trolley forging furnaceat work,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,it has the functions of hardening and tempering, Casting heating, heat treatment, anneal and temper,It is a forging heating device using gas as fuel.,It has the functions of Energy conservation and environmental protection, Metal tempering, Metal forging heating, Metal melting and casting and Metal heat treatment,it can be used in heat treatment, machinery, Household necessities, surface treatment, Machinery manufacturing and other industries。

Energy saving trolley forging furnace

6、Energy saving trolley forging furnace function

Energy saving trolley forging furnacemultifunctional, with functions such as normalizing, Forging heating, anneal, Casting heating and heat treatment,the advantage is It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、Suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.、Natural gas is mainly used as fuel, but some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.、Natural gas is used as a heat source, resulting in less waste gas and smoke after combustion, and less pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.、Adopting advanced combustion technology and control system can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.,It is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,Simple structure and reliable operation.,it is usually composed of furnace chamber, combustor, recovery of waste heat, ventilation system and Radiation chamber,Structure consists of convection chamber, ventilation system, furnace chamber, recovery of waste heat, convection chamber and so on。

Energy saving trolley forging furnace

Energy saving trolley forging furnaceis a popular Energy saving trolley forging furnace,multifunctional, with functions such as temper, hardening and tempering, Forging heating, quench and normalizing,It can be used for Metal forging heating, Metal melting and casting, Metal heat treatment, Metal tempering, Energy conservation and environmental protection, Improve production efficiency and so on。

Related recommendation

-

What is a Chain plate forging furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

Introduction to Metal Heat Treatment Natural Gas Trolley Furnace and heating furnace working principle

2025-5-27 -

Introduction to Fully automatic multi well heating furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

What is a Full fiber medium temperature natural gas trolley furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Large industrial resistance furnace, introduction to Trolley resistance furnace advantages and characteristics

2025-5-27 -

Introduction to Well type annealing furnace, how much is the price of the Forging furnace?

2025-5-27 -

What is a Rotary bottom annular heating furnace? forging furnace specifications, models, and parameters

2025-5-27 -

What is a Automatic temperature regulating chain with annealing furnace? Introduction to the advantages and characteristics of heating furnace functions

2025-5-27 -

What is a Pressure type annealing industrial furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27 -

Introduction to Deep well high-temperature annealing furnace, introduction to Forging furnace advantages and characteristics

2025-5-27