Introduction to Double beam walking back and forth furnace, introduction to heating furnace advantages and characteristics

Double beam walking back and forth furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,is an advanced Double beam walking back and forth furnace developed by our company in combination with the actual situation of the industry。

1、Brief introduction of Double beam walking back and forth furnace

Double beam walking back and forth furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,is a kind of high quality and low price Double beam walking back and forth furnace,is developed and improved by One-combustion energy saving。

Double beam walking back and forth furnace

2、Double beam walking back and forth furnace structure composition

The Double beam walking back and forth furnace structure is introduced as follows:

- combustor

- combustor

- convection chamber

- Radiation chamber

- Waste heat recovery system

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

The heat load of the main place for Double beam walking back and forth furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

Double beam walking back and forth furnace

3、Video analysis of Double beam walking back and forth furnace

On-site aerial photography of Double beam walking back and forth furnace。

Double beam walking back and forth furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd features include Stable and reliable, energy saving and environmental protection, energy-efficient, Easy to control and Easy to maintain。

4、Double beam walking back and forth furnace use

The purpose of Double beam walking back and forth furnace is introduced as follows:

- Metal heat treatment

- Metal tempering

- Metal heat treatment

- Energy conservation and environmental protection

- Improve production efficiency

In addition to forging heating, Double beam walking back and forth furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

By properly heating and cooling the metal material, the Double beam walking back and forth furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

In addition to forging heating, Double beam walking back and forth furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

The Double beam walking back and forth furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

The Double beam walking back and forth furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

Double beam walking back and forth furnace

5、How much is the Double beam walking back and forth furnace?

The Double beam walking back and forth furnace price is introduced as follows:

- technology content

- service

- Configuration difference

- Quality advantages and disadvantages

- brand

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Double beam walking back and forth furnace manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Double beam walking back and forth furnace price can meet the purchasing needs of customers.

Products of the same style, different configurations, the product price is definitely different, therefore, the Double beam walking back and forth furnace price is affected by the configuration, and the price varies.

Quality generally refers to the quality of the product. The better the quality, the higher the quality of the product. Because the quality is directly proportional to the cost of the product, the price of the Double beam walking back and forth furnace will vary greatly. One-combustion energy saving attaches great importance to the quality of products, and the formulation of prices is also reasonable.

Different brands of products in the same series have more or less differences in product prices, and different brands of Double beam walking back and forth furnace have more or less differences in price.

Double beam walking back and forth furnace

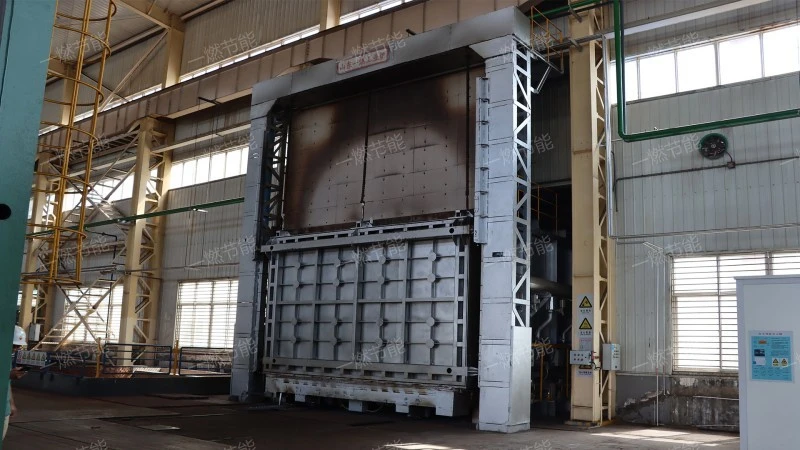

6、High-definition map of One-combustion energy saving workshop

The finished products of the Double beam walking back and forth furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Double beam walking back and forth furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Double beam walking back and forth furnaceIt is a forging heating device using gas as fuel.,It has the functions of Metal heat treatment, Metal melting and casting, Energy conservation and environmental protection, Metal forging heating and Improve production efficiency。

Related recommendation

-

What is a High manganese steel trolley forging furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Circular deep well furnace and heating furnace working principle

2025-5-27 -

Introduction to Gas-fired regenerative walking industrial furnace and heating furnace structure principle

2025-5-27 -

What is a Electric heating continuous annealing furnace? Introduction to the advantages and characteristics of the Trolley resistance heating furnace

2025-5-27 -

What is a Roll trolley forging furnace? Introduction to the Working Principle of forging furnace

2025-5-27 -

Introduction to Environmental protection chain furnace and heating furnace working principle

2025-5-27 -

What is a Rotary step heating furnace? heating furnace specifications, models, and parameters

2025-5-27 -

What is a Double car baking furnace? Introduction to the advantages and characteristics of heating furnace functions

2025-5-27 -

Introduction to Denitrification equipment for steel pipe heating furnace and SCR denitration structure principle

2025-5-27 -

Introduction to High temperature multi well heating furnace and Forging furnace advantages and features

2025-5-27