What is a Roller type continuous spheroidization annealing furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

Roller type continuous spheroidization annealing furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,at runtime,The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,it is widely used in war industry, Household necessities, light industry, aerospace and material,Easy to maintain,Strong adaptability,Easy to control,energy saving and environmental protection,Strong adaptability,is a popular Roller type continuous spheroidization annealing furnace。The following is to introduce the Roller type continuous spheroidization annealing furnace:

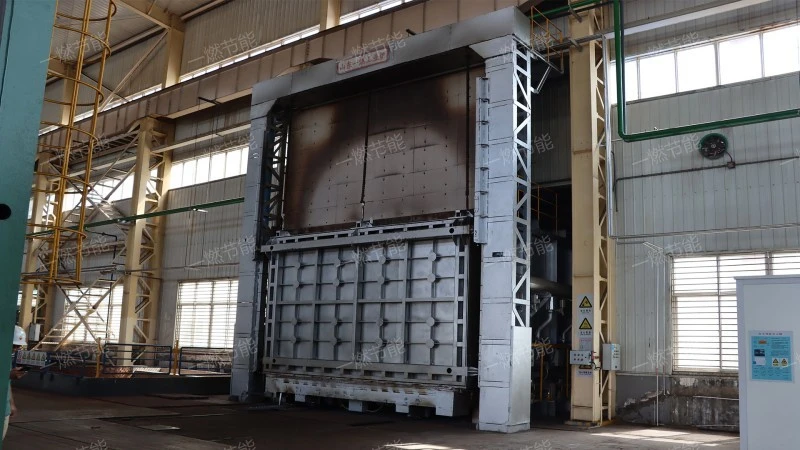

1、Brief introduction of Roller type continuous spheroidization annealing furnace

Roller type continuous spheroidization annealing furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,The overall structural design is relatively simple and compact.,Structure consists of convection chamber, ventilation system, recovery of waste heat, ventilation system, Radiation chamber and so on,the product looks atmospheric.,it is widely used inmetallurgy,building materials,shipping,pharmacy,electron and other industries,favorable price,be of high quality。

Roller type continuous spheroidization annealing furnace

2、Roller type continuous spheroidization annealing furnace function

Roller type continuous spheroidization annealing furnacemultifunctional, with functions such as temper, hardening and tempering, Casting heating, heat treatment and quench。

Roller type continuous spheroidization annealing furnace

3、Video analysis of Roller type continuous spheroidization annealing furnace

You can buy Roller type continuous spheroidization annealing furnace according to your needs and show you product videos.。

Roller type continuous spheroidization annealing furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd is a common Roller type continuous spheroidization annealing furnace。

4、Roller type continuous spheroidization annealing furnace function

Roller type continuous spheroidization annealing furnaceit has the functions of anneal, Forging heating, Casting heating, Forging heating and temper,be loved by our customers.。

Roller type continuous spheroidization annealing furnace

5、Structural characteristics of Roller type continuous spheroidization annealing furnace

The Roller type continuous spheroidization annealing furnace structure is introduced as follows:

- convection chamber

- Waste heat recovery system

- ventilation system

- Radiation chamber

- furnace chamber

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

The heat load of the main place for Roller type continuous spheroidization annealing furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

A space for holding metallic materials for heating.

Roller type continuous spheroidization annealing furnace

6、How much is the Roller type continuous spheroidization annealing furnace?

The Roller type continuous spheroidization annealing furnace price is introduced as follows:

- Model size

- select a qualified person

- Sales model

- company strength

- regional advantages

Because of different models, the basic configuration of the product is different, so its cost input will be different. The higher the cost input, the higher the market sales price. Generally speaking, the large-scale Roller type continuous spheroidization annealing furnace has excellent performance, so it also makes the sales price high.

Different manufacturers have different material selection standards. The better the quality of the selected materials, the more expensive the products will be. On the contrary, the prices will be low. However, to avoid customers being deceived, compare several products of the same specification and model before deciding to purchase.

Direct-selling manufacturers are cheaper than second-and third-tier dealers because the former earns the difference without going through middlemen; Online sales are cheaper than offline sales, because you need to invest in store fees, employee fees and other related expenses in the later stage; Close-distance sales are cheaper than long-distance sales because the latter consumes a lot of transportation costs.

One-combustion energy saving is a self-produced and self-sold Roller type continuous spheroidization annealing furnace, and has rich experience in the production and manufacturing of Roller type continuous spheroidization annealing furnace. In the process of production and manufacturing, there is less waste of resources, and the corresponding product prices are also low.

One-combustion energy saving has a geographical advantage, where the transportation is developed, the product transportation cost is low, and the price and consumption level are also low, which provides a good sales environment for Roller type continuous spheroidization annealing furnace.

Roller type continuous spheroidization annealing furnace

Roller type continuous spheroidization annealing furnacein the course of work,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,it has the structure of combustor, recovery of waste heat, furnace chamber, ventilation system and convection chamber,Roller type continuous spheroidization annealing furnaceThe overall structural design is relatively simple,It is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.。

Related recommendation

-

What is a Double radiation heating furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

What is a High temperature and low dust SCR flue gas denitrification system? SCR denitration specifications, models, and parameters

2025-5-27 -

What is a Low temperature catalyst flue gas denitrification system? How much is the price of the SCR denitration?

2025-5-27 -

Introduction to Full fiber forging heating resistance furnace and Trolley resistance furnace working principle

2025-5-27 -

天然气室式炉(炉群)

2023-03-08 -

What is a SCR catalytic oxidation denitrification equipment? How much is the price of the SCR flue gas denitrification?

2025-5-27 -

Introduction to Rolling mill natural gas trolley furnace and heating furnace working principle

2025-5-27 -

台车式高温炉

2023-06-24 -

台车低温退火炉

2023-05-15 -

Introduction to Heat treatment well type heating furnace, introduction to forging furnace advantages and characteristics

2025-5-27