Introduction to Continuous roll quenching and tempering heat treatment furnace and Forging furnace working principle

Continuous roll quenching and tempering heat treatment furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,can be customized according to user's needs.。

1、Brief introduction of Continuous roll quenching and tempering heat treatment furnace

Continuous roll quenching and tempering heat treatment furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.。

Continuous roll quenching and tempering heat treatment furnace

2、Continuous roll quenching and tempering heat treatment furnace use

The purpose of Continuous roll quenching and tempering heat treatment furnace is introduced as follows:

- Metal forging heating

- Metal tempering

- Metal melting and casting

- Improve production efficiency

- Metal forging heating

The Continuous roll quenching and tempering heat treatment furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

By properly heating and cooling the metal material, the Continuous roll quenching and tempering heat treatment furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

Although it is mainly used for forging heating, some types of Continuous roll quenching and tempering heat treatment furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

The Continuous roll quenching and tempering heat treatment furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

The Continuous roll quenching and tempering heat treatment furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

Continuous roll quenching and tempering heat treatment furnace

3、Continuous roll quenching and tempering heat treatment furnace characteristics

The Continuous roll quenching and tempering heat treatment furnace features are as follows:

- Efficient heating

- Stable and reliable

- energy saving and environmental protection

- Easy to maintain

- Stable and reliable

The Continuous roll quenching and tempering heat treatment furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

The Continuous roll quenching and tempering heat treatment furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

Natural gas is a kind of clean energy, which produces less waste gas and waste smoke after combustion and has little environmental pollution. At the same time, through wall regenerative combustion technology, flue gas waste heat recovery system and other technical means, the Continuous roll quenching and tempering heat treatment furnace further improves energy utilization efficiency and reduces energy consumption and emissions.

The structural design of the Continuous roll quenching and tempering heat treatment furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The Continuous roll quenching and tempering heat treatment furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

Continuous roll quenching and tempering heat treatment furnace

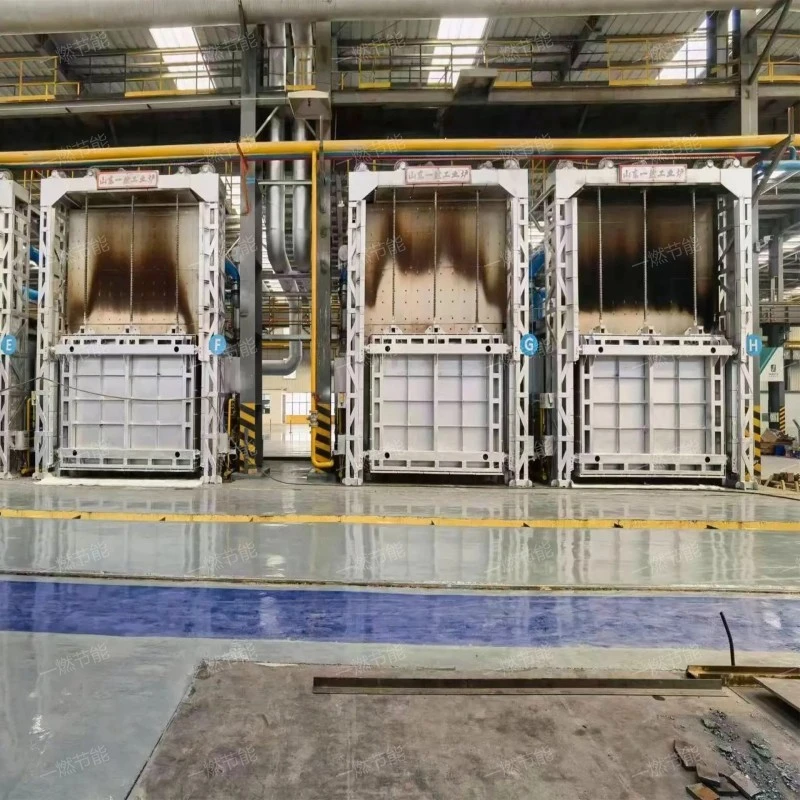

4、Continuous roll quenching and tempering heat treatment furnace field real shot

Continuous roll quenching and tempering heat treatment furnace HD real shot, showing the product style.。

Continuous roll quenching and tempering heat treatment furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Video analysis of Continuous roll quenching and tempering heat treatment furnace

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site Continuous roll quenching and tempering heat treatment furnacet operation, and helps customers to deeply understand the Continuous roll quenching and tempering heat treatment furnace production process and production site, and gain favorable comments and recognition from customers.。

Continuous roll quenching and tempering heat treatment furnace

As you can see from the live video.,One-combustion energy saving the product looks beautiful.。

6、Continuous roll quenching and tempering heat treatment furnace price concessions

The Continuous roll quenching and tempering heat treatment furnace price is introduced as follows:

- Proper management mode

- product model

- product quality

- market competition

- Manufacturer scale

Each manufacturer's sales model is different, and the preferential degree of products is also different. Some manufacturers adopt the mode of "thin profit and quick turnover", and the price is relatively cheap. Some manufacturers sell their products at high prices to earn high profits. When purchasing products, they must compare the prices to avoid being cheated.

Different customers need different output, different specifications, different product configurations, and their Continuous roll quenching and tempering heat treatment furnace prices are also different. The bigger the specification, the stronger the performance of the product and the higher the quotation.

The selling price of excellent quality products is also high, so customers should also consider the quality and price of products comprehensively in the process of purchasing products, so as to buy products with high cost performance.

When the market demand for Continuous roll quenching and tempering heat treatment furnace is relatively high, manufacturers will raise the price in order to get more profits. On the contrary, when the market demand for this product is low, manufacturers will lower the price in order to sell the remaining products as soon as possible.

Although there are many manufacturers of products in Jinan, there are certain differences in the scale and strength of each manufacturer. Some manufacturers are large in scale and strength, some are small in scale, and some manufacturers do not have their own production workshops and belong to middlemen. Relatively speaking, the prices of products formulated by middlemen are higher.

Continuous roll quenching and tempering heat treatment furnace

Continuous roll quenching and tempering heat treatment furnaceit has the characteristics of energy-efficient, energy saving and environmental protection, Stable and reliable, Strong adaptability and Easy to maintain,It is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.。

Related recommendation

-

Introduction to SCR medium temperature flue gas denitrification, SCR denitration system advantages, characteristics and principles

2025-5-27 -

What is a Titanium alloy heat treatment trolley forging heating furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

What is a Local annealing furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

Introduction to Gas storage gas trolley furnace and Forging furnace working principle

2025-5-27 -

Introduction to Trolley type low-temperature annealing furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Carbon fiber gas trolley furnace, how much is the price of the forging furnace?

2025-5-27 -

What is a Side door trolley furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

What is a Bright Annealing Resistance Furnace? Introduction to the Working Principle of Trolley resistance heating furnace

2025-5-27 -

What is a Multi stage natural gas trolley furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Energy saving and environmentally friendly chamber furnace, how much is the price of the forging furnace?

2025-5-27