What is a Well type high-temperature heating furnace? Introduction to the advantages and characteristics of the heating furnace

Well type high-temperature heating furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,It can be used for Metal melting and casting, Metal forging heating, Metal heat treatment, Energy conservation and environmental protection, Metal melting and casting, Metal tempering and so on,Simple structure and reliable operation.,it mainly includes convection chamber, ventilation system, Radiation chamber, ventilation system and furnace chamber,was developed and designed by One-combustion energy saving。The following is to introduce the Well type high-temperature heating furnace:

1、Brief introduction of Well type high-temperature heating furnace

Well type high-temperature heating furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,at runtime,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.。

Well type high-temperature heating furnace

2、Well type high-temperature heating furnace function

Well type high-temperature heating furnacemultifunctional, with functions such as temper, normalizing, Forging heating, quench and Casting heating。

Well type high-temperature heating furnace

3、Well type high-temperature heating furnace application

Well type high-temperature heating furnaces have the following purposes.

- Metal forging heating

- Metal heat treatment

- Improve production efficiency

- Metal forging heating

- Improve production efficiency

The Well type high-temperature heating furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

In addition to forging heating, Well type high-temperature heating furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

The Well type high-temperature heating furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

The Well type high-temperature heating furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

The Well type high-temperature heating furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

Well type high-temperature heating furnace

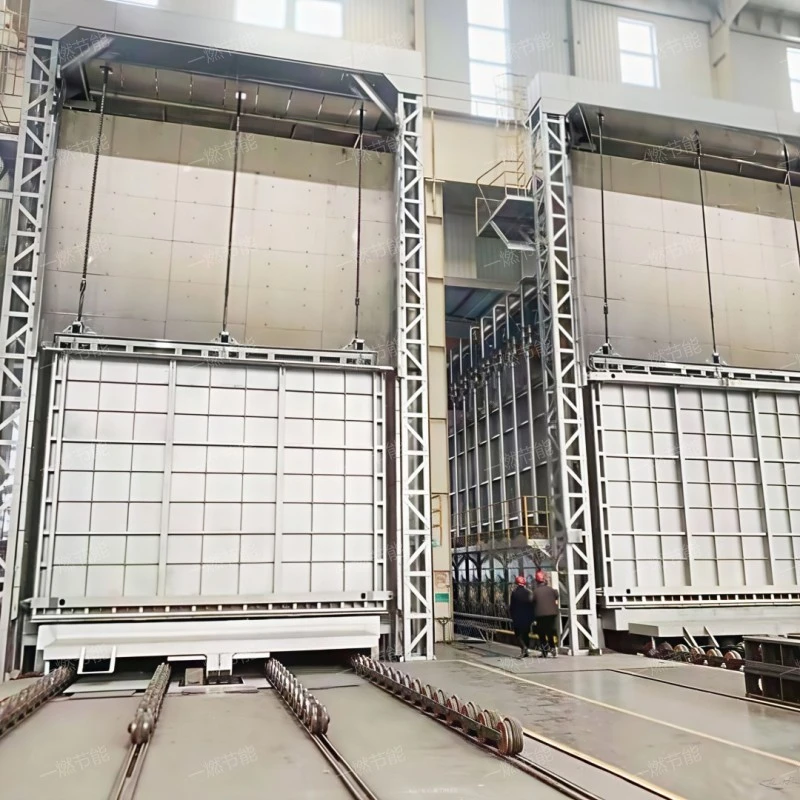

4、Well type high-temperature heating furnace real shot picture

HD pictures of Well type high-temperature heating furnace of different specifications and models。

Well type high-temperature heating furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Well type high-temperature heating furnace price concessions

The Well type high-temperature heating furnace price is introduced as follows:

- Cost input

- raw material

- product function

- Manufacturer's strength

- regional difference

When it comes to cost, I believe everyone has heard the saying "You get what you want for a price", which shows that the upfront cost of a product is directly proportional to its value. The upfront cost is high, the value is high, the quality is good, and the price is naturally high. The less the cost is, the lower the price is, and the quality is not good.

The quality of material selection is one of the main factors that directly affect the Well type high-temperature heating furnace. If the quality of material selection is better, the price may be more expensive. Therefore, customers must first understand the quality of material selection before purchasing products, and then compare whether the quality and price match.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The products manufactured by manufacturers of different scales are also different. Large-scale manufacturers have advanced production technology, the quality of products manufactured is reliable, and large-scale manufacturers have perfect after-sales service, which can provide greater protection for customers and the products manufactured are more cost-effective. Therefore, customers should try to choose large manufacturers to purchase.

There are differences in consumption levels in different regions, which directly affect the production and manufacturing costs of products. Generally speaking, the higher the consumption level, the higher the cost of producing products, and the higher the product cost, the higher the price naturally.

Well type high-temperature heating furnace

6、Company selection

Choosing a suitable Well type high-temperature heating furnace manufacturer requires comprehensive consideration of many aspects. First of all, we should examine the strength of manufacturers, including production capacity, R&D team and industry experience. Strong manufacturers can better ensure product supply and innovation ability. Secondly, product quality is the key, and it is evaluated by product certification, material selection and manufacturing process to ensure the durability of products. Product performance can not be ignored, so we should choose manufacturers with matching technical parameters, rich types and customized services according to actual needs. After-sales service is equally important. Professional and timely service team, perfect after-sales content and extensive service network can make users worry about nothing. In addition, market reputation is also an important reference. We can understand the reputation and status of manufacturers through customer evaluation, industry reputation and award-winning honor. Finally, it is necessary to analyze the price and cost performance, and on the premise of ensuring the quality and performance, choose a manufacturer with reasonable price and high cost performance, so as to purchase Well type high-temperature heating furnace products that meet the demand and have good cost performance.。

One-combustion energy saving

Well type high-temperature heating furnaceIt can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.、Natural gas is used as a heat source, resulting in less waste gas and smoke after combustion, and less pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.、Suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.、Using regenerative combustion system or advanced burner design can realize the uniform distribution of temperature in the furnace, ensure the uniform heating of metal materials and improve product quality.、Adopting advanced combustion technology and materials, it has a long service life and low maintenance cost.,It is a product series that integrates Improve production efficiency, Energy conservation and environmental protection, Metal melting and casting, Metal tempering and Metal heat treatment,at work,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.。

Related recommendation

-

What is a Environmentally friendly tubular roaster? Forging furnace specifications, models, and parameters

2025-5-27 -

What is a Automatic temperature control trolley heating furnace? Introduction to the Working Principle of forging furnace

2025-5-27 -

Introduction to High power industrial resistance furnace and Trolley resistance furnace structure principle

2025-5-27 -

What is a Steel chain quenching furnace? How much is the price of the heating furnace?

2025-5-27 -

Introduction to Mobile trolley heating furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

回火台车炉

2023-08-26 -

What is a Natural gas trolley forging furnace? Introduction to the Working Principle of forging furnace

2025-5-27 -

Introduction to Continuous roll solid solution quenching furnace, how much is the price of the forging furnace?

2025-5-27 -

What is a Rotary bottom continuous heating furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

Introduction to Natural gas storage tube quenching furnace, how much is the price of the heating furnace?

2025-5-27