Introduction to SCR medium temperature denitrification and SCR flue gas denitrification working principle

SCR medium temperature denitrificationthe full name is selective catalytic reduction technology, which is an advanced flue gas denitrification technology.。The following is to introduce the SCR medium temperature denitrification:

1、Brief introduction of SCR medium temperature denitrification

SCR medium temperature denitrificationthat is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.,The structural design is more advanced and reasonable.,Structure consists of Flue gas mixing and distribution system, control system, Catalyst supply system, Temperature control and monitoring system, Catalyst reactor and so on,is a common SCR medium temperature denitrification,it has the functions of Improve working conditions, Improve energy efficiency, environmental protection, Improve working conditions and Improve energy efficiency,usually used in Gas power plant, building materials, metallurgy, iron and steel plant, coal-fired power station and other fields。

SCR medium temperature denitrification

2、Advantages of SCR medium temperature denitrification principle

SCR medium temperature denitrificationin the course of work,Ammonia gas or other suitable reducing agent (such as urea aqueous solution) is sprayed into the flue gas upstream of the catalyst at high temperature. Under the action of catalyst, the reducing agent selectively reacts with nitrogen oxides (NOx) in flue gas to generate pollution-free nitrogen and water vapor. Because NH3 is selective, it only reacts with NOx and basically does not react with O2, so this technology is called selective catalytic reduction denitrification.,the product looks atmospheric.,Widely used inFlue gas denitrification,Improve product quality,Meet the requirements of environmental protection,environmental protection,Meet the requirements of environmental protection and so on。

SCR medium temperature denitrification

3、SCR medium temperature denitrification structure composition

The SCR medium temperature denitrification structure is introduced as follows:

- Reducing agent storage and supply system

- control system

- Reactor

- Flue gas mixing and distribution system

- Reducing agent supply

Used to store and supply reducing agent (such as ammonia or urea solution) to the reactor.

The whole SCR medium temperature denitrification is automatically controlled to ensure the stable operation of the system and achieve the expected denitration effect.

It is the core component of SCR medium temperature denitrification technology, and it is equipped with catalyst to promote the chemical reaction between reductant and NOx.

Ensure that the flue gas and reducing agent are fully mixed in the reactor to improve the denitrification efficiency.

Reducing agents such as liquid pure ammonia or ammonia water (aqueous solution of ammonia) are evaporated and mixed with diluted air or flue gas.

SCR medium temperature denitrification

4、SCR medium temperature denitrification display

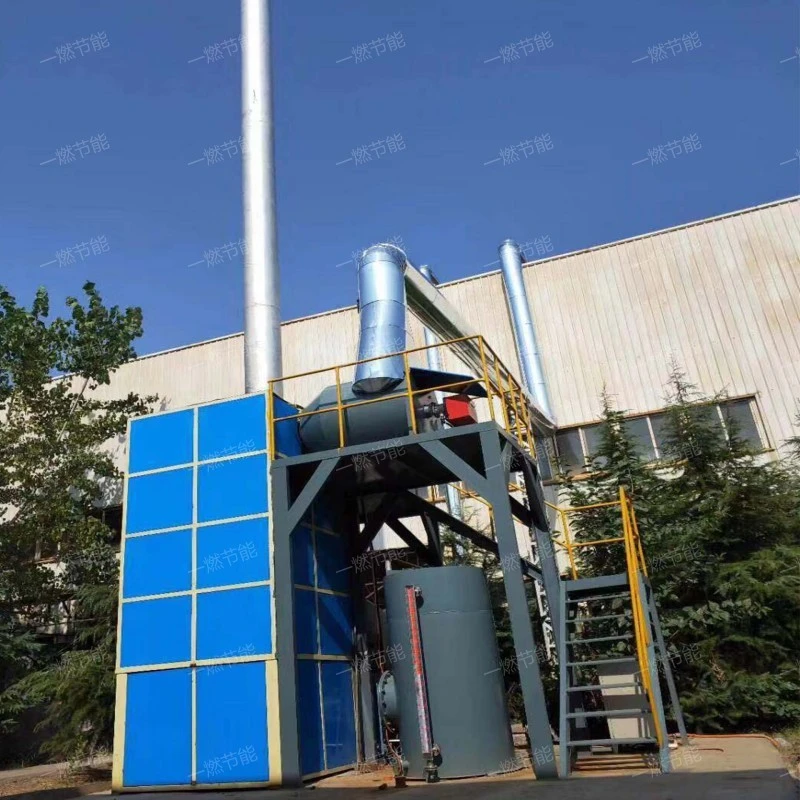

The SCR medium temperature denitrification is designed by One-combustion energy saving with advanced technology, and the product has high performance advantages. In order to facilitate our customers to find a satisfactory SCR flue gas denitrification more quickly, the following high-definition pictures are provided for reference.。

SCR medium temperature denitrification

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、SCR medium temperature denitrification function

SCR medium temperature denitrificationmultifunctional, with functions such as Promote sustainable development, environmental protection, Improve working conditions, environmental protection and Promote sustainable development,it is an ideal choice for customers to buy SCR medium temperature denitrification。

SCR medium temperature denitrification

6、SCR medium temperature denitrification price advantage

The SCR medium temperature denitrification price is introduced as follows:

- raw material

- market demand

- Service factor

- model

- Brand strength

The higher the cost of materials, the higher the price will be. In the process of purchasing, customers need to make a detailed understanding of the materials selected for manufacturing products.

If there is a large demand for SCR medium temperature denitrification in the market, the price of products will naturally be high. On the other hand, if the supply of this equipment exceeds demand, then manufacturers will have inventory accumulation. In order to dispose of these products as soon as possible, some manufacturers will sell them by lowering the price of products, so the price will be very low.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the SCR medium temperature denitrification price and service can meet the actual needs of customers.

Different models will have different specifications, which will lead to greater differences in the comprehensive configuration of products, which will also lead to greater changes in prices.

At present, there are various brands of SCR medium temperature denitrification in Jinan, Shandong province. The performance, quality and after-sales of products under different brands are different, and the prices of SCR medium temperature denitrification are different.

SCR medium temperature denitrification

SCR medium temperature denitrificationdelective catalytic reduction technology is an efficient flue gas denitrification technology.,the principle is simple.Catalysts are used to promote the selective catalytic reduction reaction between reducing agents (such as ammonia and urea) and NOx in flue gas. Under the action of catalyst, the reductant preferentially reacts with NOx to generate harmless nitrogen and water vapor, but hardly reacts with oxygen in flue gas. This chemical reaction is usually carried out in the temperature range of 200-450℃, and the specific reaction temperature depends on the type of catalyst selected.,is a popular SCR medium temperature denitrification。

Related recommendation

-

Introduction to Pit type heat treatment quenching furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

What is a Stepping industrial furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Multi tube continuous annealing furnace and forging furnace working principle

2025-5-27 -

What is a Air quenching natural gas trolley furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

Introduction to Regenerative burner stepper heating furnace and heating furnace working principle

2025-5-27 -

防爆台车锻造炉

2023-08-10 -

What is a Chain continuous heating furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

What is a Full fiber annealing trolley furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

Introduction to SCR catalytic oxidation flue gas denitrification, advantages, characteristics and principles of SCR flue gas denitrification

2025-5-27 -

What is a Multi stage trolley forging heating furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27