What is a Low temperature SCR denitrification? Introduction to the advantages and characteristics of the SCR flue gas denitrification

Low temperature SCR denitrificationis an efficient, stable and environment-friendly flue gas denitrification technology.,at the start of the operation,Under the action of catalyst, reducing agents (such as ammonia, urea, etc.) react with nitrogen oxides in flue gas to convert them into harmless nitrogen and water vapor.,The structural design is more advanced and reasonable.,it is usually composed of Catalyst reactor, Temperature control and monitoring system, control system, Catalyst supply system and Flue gas mixing and distribution system,multifunctional, with functions such as environmental protection, Promote sustainable development, Improve energy efficiency, environmental protection and Improve working conditions,it is an ideal choice for customers to buy Low temperature SCR denitrification。

1、Brief introduction of Low temperature SCR denitrification

Low temperature SCR denitrificationthat is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.,the main features are Stable operation, High denitration efficiency, Good selectivity, Mature technology and Strong adaptability。

Low temperature SCR denitrification

2、Low temperature SCR denitrification application

Low temperature SCR denitrificationIt is a product series that integrates Promote sustainable development, Flue gas denitrification, environmental protection, Improve product quality and Improve product quality,has been favored by more and more customers.。

Low temperature SCR denitrification

3、Structural advantages of Low temperature SCR denitrification

The Low temperature SCR denitrification has the following structure

- Flue gas mixing and distribution

- Catalytic reduction reaction

- control system

- Reactor

- Flue gas mixing and distribution

The mixed reducing agent and flue gas are fully mixed in the mixing tube and evenly distributed to the catalyst reactor through the distribution system.

Under the action of catalyst, the reductant and NOx in flue gas undergo selective catalytic reduction reaction to generate nitrogen and water vapor.

The whole Low temperature SCR denitrification is automatically controlled, including the adjustment of reducing agent supply, flue gas flow and temperature, so as to ensure the stable operation of the system and achieve the expected denitrification effect.

It is the core component of Low temperature SCR denitrification technology, and it is equipped with catalyst to promote the chemical reaction between reductant and NOx.

The mixed reducing agent and flue gas are fully mixed in the mixing tube and evenly distributed to the catalyst reactor through the distribution system.

Low temperature SCR denitrification

4、Video analysis of Low temperature SCR denitrification

You can buy Low temperature SCR denitrification according to your needs and show you product videos.。

Low temperature SCR denitrification

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd it is mainly composed of Catalyst reactor, Temperature control and monitoring system, Flue gas mixing and distribution system, Catalyst supply system and control system,This productThe overall structural design is relatively simple and compact.。

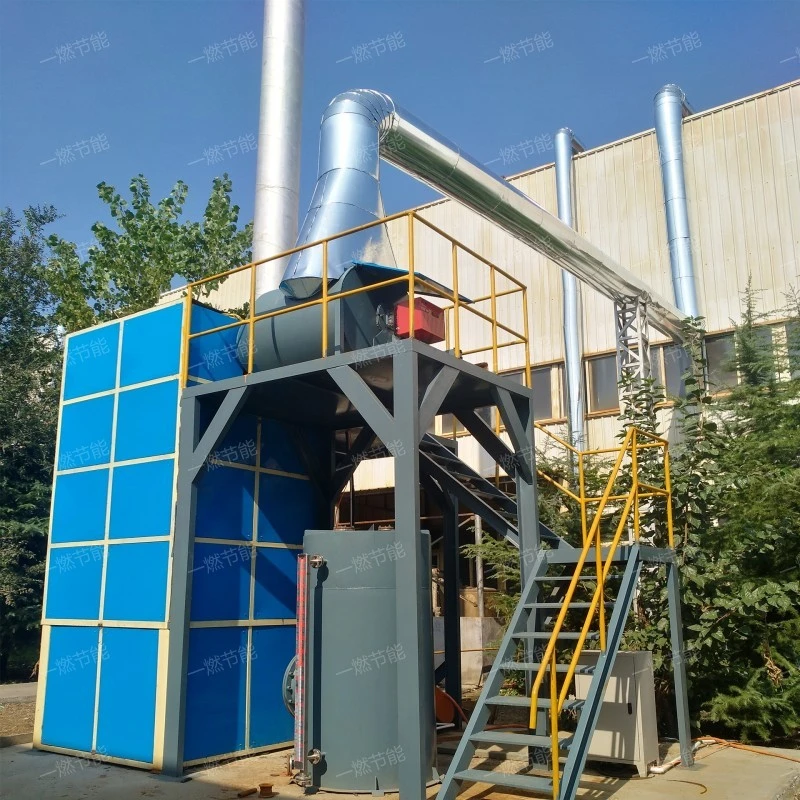

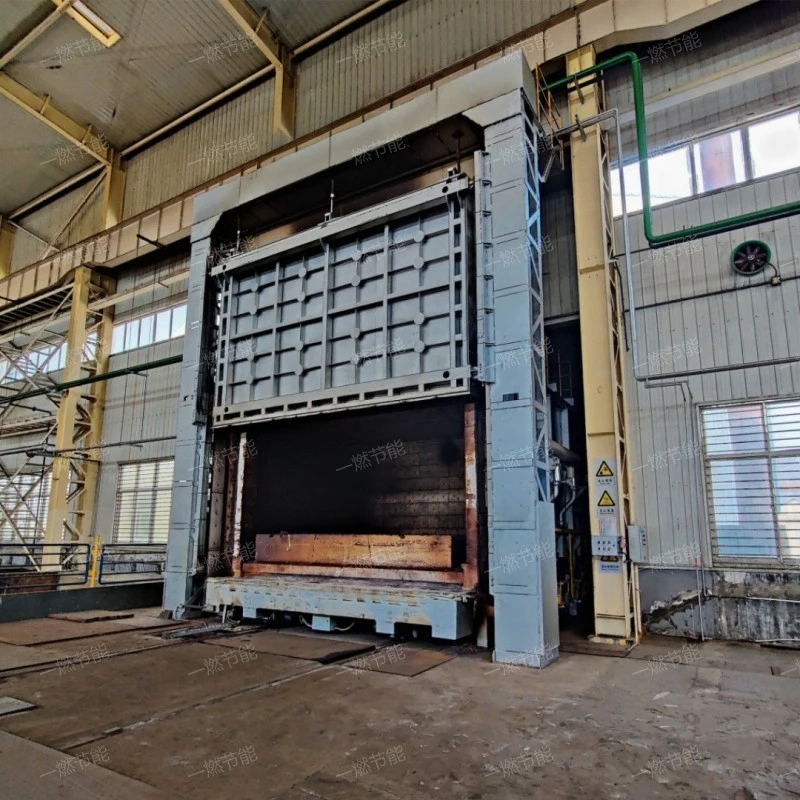

5、Low temperature SCR denitrification work site real shot

HD pictures of Low temperature SCR denitrification of different specifications and models。

Low temperature SCR denitrification

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

Low temperature SCR denitrificationit has the functions of Promote sustainable development, environmental protection, Improve energy efficiency, Improve working conditions and Promote sustainable development,at work,Catalysts are used to promote the selective catalytic reduction reaction between reducing agents (such as ammonia and urea) and NOx in flue gas. Under the action of catalyst, the reductant preferentially reacts with NOx to generate harmless nitrogen and water vapor, but hardly reacts with oxygen in flue gas. This chemical reaction is usually carried out in the temperature range of 200-450℃, and the specific reaction temperature depends on the type of catalyst selected.。

Related recommendation

-

What is a Energy saving and environmentally friendly chain annealing furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

What is a Dual car rapid quenching furnace? How much is the price of the heating furnace?

2025-5-27 -

What is a Multi tube continuous bright annealing furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

What is a High temperature all fiber trolley forging heating furnace? Forging furnace specifications, models, and parameters

2025-5-27 -

膜壳焙烧炉

2023-04-11 -

Introduction to Low temperature oxidation flue gas denitrification equipment outside the furnace and SCR flue gas denitrification advantages and features

2025-5-27 -

What is a Stepping bottom annular heating furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Regenerative burner heat treatment chain furnace and forging furnace advantages and features

2025-5-27 -

What is a Direct heating furnace? How much is the price of the heating furnace?

2025-5-27 -

Introduction to Well type heating furnace and forging furnace advantages and features

2025-5-27