Introduction to Heating furnace flue gas denitrification system in forging plant, SCR denitration system advantages, characteristics and principles

Heating furnace flue gas denitrification system in forging plantis an efficient, stable and environment-friendly flue gas denitrification technology.。The following is to introduce the Heating furnace flue gas denitrification system in forging plant:

1、Brief introduction of Heating furnace flue gas denitrification system in forging plant

Heating furnace flue gas denitrification system in forging plantit refers to the process of removing nitrogen oxides from flue gas to reduce environmental pollution. NOx is a pollutant harmful to the atmospheric environment, which has strong irritation and toxicity, and will lead to environmental problems such as acid rain and photochemical smog, and also endanger human health. The main principle of flue gas denitrification technology is to reduce NOx to nitrogen and water by adding appropriate reducing agent or catalyst in the combustion process or flue gas treatment system, so as to reduce NOx emission.,it is mainly composed of Temperature control and monitoring system, Flue gas mixing and distribution system, control system, Catalyst supply system and Catalyst reactor,productThe structural design is more advanced and reasonable.,in the course of work,Under the action of catalyst, reducing agents (such as ammonia, urea, etc.) react with nitrogen oxides in flue gas to convert them into harmless nitrogen and water vapor.,is a common Heating furnace flue gas denitrification system in forging plant,support customization。

Heating furnace flue gas denitrification system in forging plant

2、Structural characteristics of Heating furnace flue gas denitrification system in forging plant

The Heating furnace flue gas denitrification system in forging plant has the following structure

- Flue gas mixing and distribution system

- Catalytic reduction reaction

- control system

- Temperature control and monitoring

- Flue gas mixing and distribution

The mixed reducing agent and flue gas are fully mixed in the mixing tube and evenly distributed to the catalyst reactor through the distribution system.

Under the action of catalyst, the reductant and NOx in flue gas undergo selective catalytic reduction reaction to generate nitrogen and water vapor.

The whole Heating furnace flue gas denitrification system in forging plant is automatically controlled to ensure the stable operation of the system and achieve the expected denitration effect.

The temperature in the catalyst reactor is maintained within the optimal reaction temperature range through the temperature control and monitoring system.

Ensure that the flue gas and reducing agent are fully mixed in the reactor to improve the denitrification efficiency.

Heating furnace flue gas denitrification system in forging plant

3、Heating furnace flue gas denitrification system in forging plant function

Heating furnace flue gas denitrification system in forging plantit has the functions of Improve energy efficiency, Improve working conditions, Promote sustainable development, Improve working conditions and environmental protection,it is an ideal choice for customers to buy Heating furnace flue gas denitrification system in forging plant。

Heating furnace flue gas denitrification system in forging plant

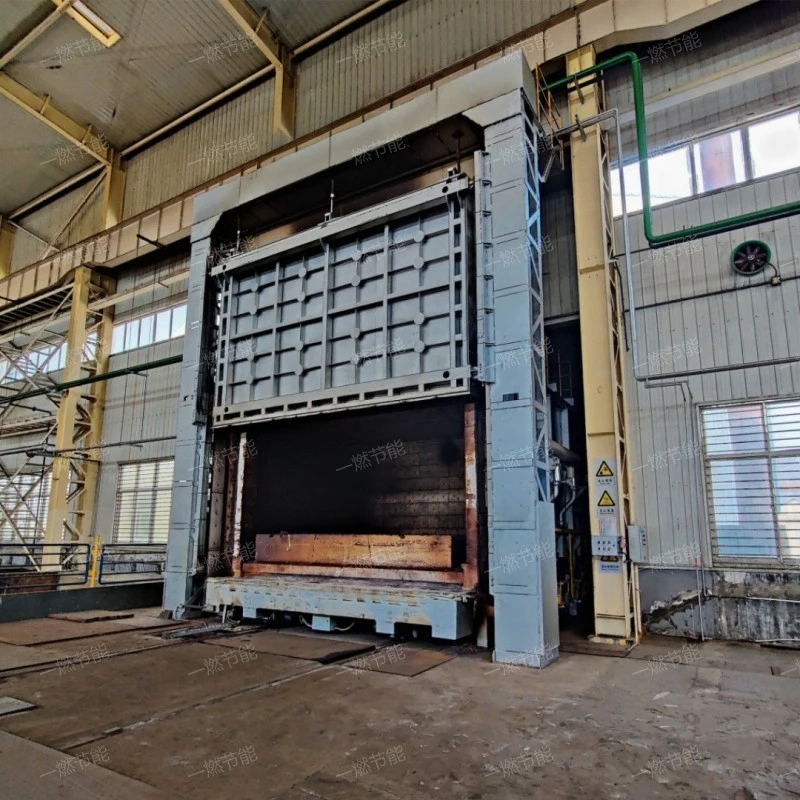

4、Heating furnace flue gas denitrification system in forging plant work site real shot

High-definition pictures for various Heating furnace flue gas denitrification system in forging plant, panoramic display,the product looks beautiful., reliable in quality and trustworthy.。

Heating furnace flue gas denitrification system in forging plant

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、How much is the Heating furnace flue gas denitrification system in forging plant?

The Heating furnace flue gas denitrification system in forging plant price is introduced as follows:

- raw material

- Model specification

- product function

- Cost input

- Service factor

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

One-combustion energy saving is a large Heating furnace flue gas denitrification system in forging plant manufacturer in Jinan, Shandong province, the Heating furnace flue gas denitrification system in forging plant of various specifications and models manufactured are affordable, reliable in quality, good in performance and perfect after-sales, which is a good choice for everyone to buy Heating furnace flue gas denitrification system in forging plant.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The cost of manufacturing Heating furnace flue gas denitrification system in forging plant varies from manufacturer to manufacturer. The higher the cost of manufacturing products, the higher the product price will be. On the other hand, the lower the production cost, the lower the product price, but the quality of products with high production cost is guaranteed, which can reduce the maintenance cost of customers.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Heating furnace flue gas denitrification system in forging plant price and service can meet the actual needs of customers.

Heating furnace flue gas denitrification system in forging plant

6、Company discount

Heating furnace flue gas denitrification system in forging plant is a new type of SCR denitration system introduced by Shandong yiran energy-saving environment protection co., ltd manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for cement plant and other industries. Now consult Heating furnace flue gas denitrification system in forging plant, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

One-combustion energy saving

Heating furnace flue gas denitrification system in forging plantWidely used in Promote sustainable development, Improve product quality, Meet the requirements of environmental protection, environmental protection and Flue gas denitrification,The structure is novel, special, advanced, reasonable and scientific.,structure mainly includes: Temperature control and monitoring system, Flue gas mixing and distribution system, Catalyst supply system, Catalyst reactor, control system and so on,the principle is simple.Under the action of catalyst, reducing agents (such as ammonia, urea, etc.) react with nitrogen oxides in flue gas to convert them into harmless nitrogen and water vapor.。

Related recommendation

-

What is a Aluminum alloy heating furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Low temperature natural gas trolley furnace and heating furnace working principle

2025-5-27 -

Introduction to Multi functional chain heat treatment furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

轧钢加热炉

2023-04-10 -

Introduction to Bright Well Heat Treatment Furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

What is a Car quenching furnace? Forging furnace specifications, models, and parameters

2025-5-27 -

What is a SCR catalytic oxidation flue gas denitrification equipment? Introduction to the principle of SCR denitration system structure

2025-5-27 -

Introduction to Trolley mold heating furnace, heating furnace specifications, model parameters

2025-5-27 -

What is a Automatic temperature control stepper industrial furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

Introduction to Multi functional chain heating furnace, how much is the price of the heating furnace?

2025-5-27