What is a Industrial quenching furnace denitrification? Introduction to the Working Principle of SCR denitration system

Industrial quenching furnace denitrificationit refers to the process of removing nitrogen oxides from flue gas to reduce environmental pollution. NOx is a pollutant harmful to the atmospheric environment, which has strong irritation and toxicity, and will lead to environmental problems such as acid rain and photochemical smog, and also endanger human health. The main principle of flue gas denitrification technology is to reduce NOx to nitrogen and water by adding appropriate reducing agent or catalyst in the combustion process or flue gas treatment system, so as to reduce NOx emission.,the product looks beautiful.,is a kind of high quality and low price Industrial quenching furnace denitrification,in the course of work,Under the action of catalyst, reducing agents (such as ammonia, urea, etc.) react with nitrogen oxides in flue gas to convert them into harmless nitrogen and water vapor.,has been favored by more and more customers.。

1、Brief introduction of Industrial quenching furnace denitrification

Industrial quenching furnace denitrificationdelective catalytic reduction technology is an efficient flue gas denitrification technology.。

Industrial quenching furnace denitrification

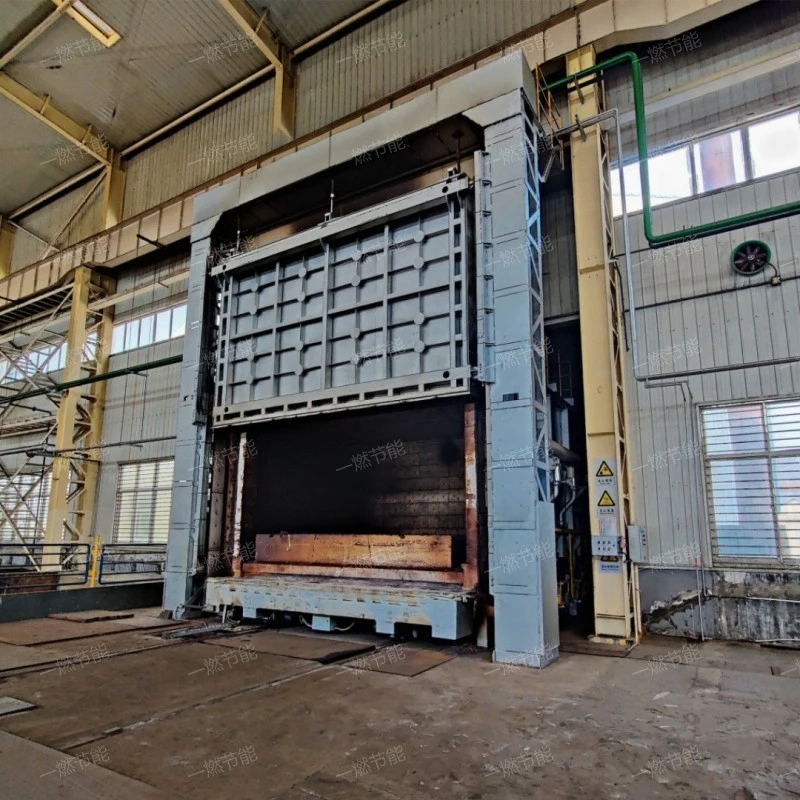

2、Physical picture of Industrial quenching furnace denitrification

High-definition picture shooting for various Industrial quenching furnace denitrification, all-round display, exquisite appearance, excellent quality and trustworthy.。

Industrial quenching furnace denitrification

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Industrial quenching furnace denitrification video detail

You can buy Industrial quenching furnace denitrification according to your needs and show you product videos.。

Industrial quenching furnace denitrification

As you can see from the live video.,One-combustion energy saving It is a product series that integrates environmental protection, Improve product quality, Promote sustainable development, Improve product quality and Flue gas denitrification。

4、Industrial quenching furnace denitrification function

Industrial quenching furnace denitrificationit has the functions of Promote sustainable development, Improve working conditions, Promote sustainable development, environmental protection and Improve energy efficiency,the product looks beautiful.,is a kind of high quality and low price Industrial quenching furnace denitrification,the main features are Environmental protection and pollution-free, High denitration efficiency, Less secondary pollution, Mature technology and Mature and stable technology,is a Industrial quenching furnace denitrification newly developed by One-combustion energy saving。

Industrial quenching furnace denitrification

5、Structural advantages of Industrial quenching furnace denitrification

The Industrial quenching furnace denitrification structure is introduced as follows:

- Reducing agent supply

- control system

- Reducing agent storage and supply system

- Reactor

- Flue gas mixing and distribution system

Reducing agents such as liquid pure ammonia or ammonia water (aqueous solution of ammonia) are evaporated and mixed with diluted air or flue gas.

The whole Industrial quenching furnace denitrification is automatically controlled, including the adjustment of reducing agent supply, flue gas flow and temperature, so as to ensure the stable operation of the system and achieve the expected denitrification effect.

Used to store and supply reducing agent (such as ammonia or urea solution) to the reactor.

It is the core component of Industrial quenching furnace denitrification technology, and it is equipped with catalyst to promote the chemical reaction between reductant and NOx.

Ensure that the flue gas and reducing agent are fully mixed in the reactor to improve the denitrification efficiency.

Industrial quenching furnace denitrification

6、Industrial quenching furnace denitrification price consultation

The Industrial quenching furnace denitrification price is introduced as follows:

- select a qualified person

- manufacturing cost

- service

- Company size

- Model specification

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

The manufacturer has a fixed raw material supplier, so that the raw material price given by the raw material supplier to the manufacturer will be lower, the raw material cost invested by the manufacturer will be reduced, and the price of the Industrial quenching furnace denitrification will also be reduced.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Industrial quenching furnace denitrification manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Industrial quenching furnace denitrification price can meet the purchasing needs of customers.

The nature of the manufacturer can also greatly affect the price of the Industrial quenching furnace denitrification. General manufacturers are divided into direct sellers, agents and middlemen. If they are direct selling manufacturers, there are not too many intermediate links, and their sales prices are low.

Products generally have a variety of specifications and models to meet the multiple needs of manufacturing. The same is true for Industrial quenching furnace denitrification, which have different models and different performances. Therefore, these are all factors that affect the price change of Industrial quenching furnace denitrification.

Industrial quenching furnace denitrification

Industrial quenching furnace denitrificationthat is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.,at the start of the operation,Ammonia gas or other suitable reducing agent (such as urea aqueous solution) is sprayed into the flue gas upstream of the catalyst at high temperature. Under the action of catalyst, the reducing agent selectively reacts with nitrogen oxides (NOx) in flue gas to generate pollution-free nitrogen and water vapor. Because NH3 is selective, it only reacts with NOx and basically does not react with O2, so this technology is called selective catalytic reduction denitrification.。

Related recommendation

-

Introduction to Resistance annealing furnace and Trolley resistance furnace structure principle

2025-5-27 -

Introduction to Trolley heat treatment resistance furnace, introduction to Trolley resistance furnace advantages and characteristics

2025-5-27 -

What is a Bright Annealing Electric Furnace? Introduction to the advantages, characteristics, and principles of the Trolley electric heating furnace

2025-5-27 -

Introduction to Steel plant circular furnace flue gas denitrification equipment, SCR flue gas denitrification advantages, characteristics and principles

2025-5-27 -

Introduction to Stepped tube billet heating furnace and heating furnace advantages and features

2025-5-27 -

What is a Automatic temperature control stepper industrial furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

Introduction to Catalytic reduction low-temperature denitrification equipment and SCR flue gas denitrification structure principle

2025-5-27 -

Introduction to Stepped beam automatic heating furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Roller bottom bright annealing furnace and Forging furnace working principle

2025-5-27 -

Introduction to De stress annealing heat treatment furnace and forging furnace working principle

2025-5-27