Introduction to Automatic opening and closing electric heating furnace and Trolley electric furnace advantages and features

Automatic opening and closing electric heating furnaceis an industrial furnace that uses electric current to generate heat energy through resistive materials, thus heating workpieces or materials.,it has been widely used in building materials, fireproofing, Special material, New material development, electron and other industries,Strong customization, the Automatic opening and closing electric heating furnace can be customized according to the actual needs of users, such as heating power, furnace size, temperature control accuracy, etc., to meet the requirements of specific processes.、The electrothermal conversion efficiency is high, and the Automatic opening and closing electric heating furnace can efficiently convert electric energy into heat energy, which is higher than the thermal efficiency of the traditional flame furnace.、The safety is high, and the Automatic opening and closing electric heating furnace is electrically controlled, which has higher safety than the fuel stove and can effectively avoid potential safety hazards such as fire and explosion.、Wide application range, the Automatic opening and closing electric heating furnace is suitable for heating workpieces of various shapes and sizes, and can meet the heating requirements of different industries and processes.、Easy to control, accurate temperature control, and easy to realize automatic control.,favorable price,reliable quality。The following is to introduce the Automatic opening and closing electric heating furnace:

1、Brief introduction of Automatic opening and closing electric heating furnace

Automatic opening and closing electric heating furnaceis an industrial equipment that uses electric current to generate heat through a resistor to heat materials.,It is the thermal effect of current, that is, when current passes through a conductor with a certain resistance, electric energy will be converted into heat energy, which will make the resistor heat up and transfer heat to the materials in the furnace.,it has the functions of Forging heating, hardening and tempering, normalizing, quench and anneal,is a kind of high quality and low price Automatic opening and closing electric heating furnace,at work,Thermal effect based on current. When current passes through resistive materials (such as resistance wires, resistance bands, etc.), due to the existence of resistance, electric energy will be converted into heat energy, which will make the resistive materials heat up. This heat is then transferred to the workpiece or material in the furnace to achieve the purpose of heating.。

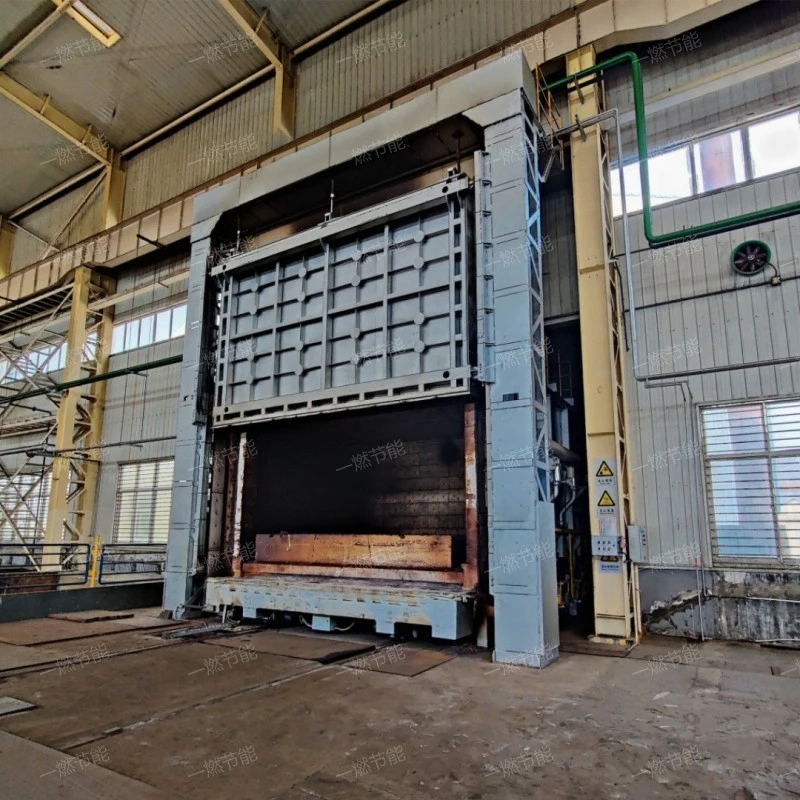

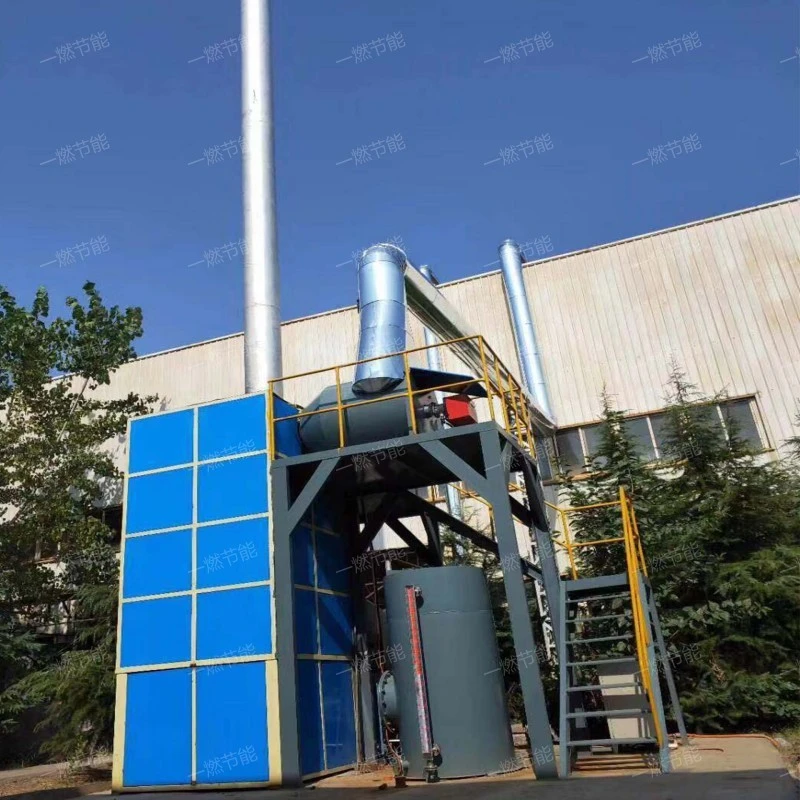

Automatic opening and closing electric heating furnace

2、Working principle of Automatic opening and closing electric heating furnace

Automatic opening and closing electric heating furnaceat runtime,It is the thermal effect of current, that is, when current passes through a conductor with a certain resistance, electric energy will be converted into heat energy, which will make the resistor heat up and transfer heat to the materials in the furnace.。

Automatic opening and closing electric heating furnace

3、Automatic opening and closing electric heating furnace structure

The Automatic opening and closing electric heating furnace structure is introduced as follows:

- furnace body

- control system

- thermal insulation (material)

- furnace shell

- furnace chamber

The furnace body is usually made of high-temperature and corrosion-resistant materials, such as high-quality steel plates, refractory bricks and ceramic fibers. These materials can withstand thermal stress and mechanical stress at high temperature, ensuring the stability and durability of the furnace body.

The control system is the command center of the Automatic opening and closing electric heating furnace, which is usually composed of temperature controller, power regulator and thermocouple. These components work together to realize real-time monitoring and automatic adjustment of the temperature in the furnace.

Thermal insulation materials are used to reduce heat loss and keep the temperature in the furnace stable. Commonly used thermal insulation materials include ceramic fibers, refractory fibers, etc. These materials have the characteristics of [commodity characteristics].

The furnace shell is usually made of steel plate for protection.

Refractory materials are built in the furnace to withstand high temperature.

Automatic opening and closing electric heating furnace

4、Automatic opening and closing electric heating furnace working site

Speak directly with facts on the spot。

Automatic opening and closing electric heating furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd the product looks beautiful.。

5、Automatic opening and closing electric heating furnace price

The Automatic opening and closing electric heating furnace price is introduced as follows:

- product model

- regional advantages

- brand

- product function

- technology

Because the specifications and models of products are different, their specifications and configurations are not the same. As we all know, the cost of products with high configuration will be higher, and vice versa, because there is a close relationship between product sales price and specifications and models.

One-combustion energy saving address:Jinan, Shandong province, the transportation here is developed and convenient, and the products can be transported to the designated place in a short time, which saves customers a sum of transportation expenses.

Different brands of products in the same series have more or less differences in product prices, and different brands of Automatic opening and closing electric heating furnace have more or less differences in price.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

Automatic opening and closing electric heating furnace

6、How to choose the right product manufacturer?

Choosing a suitable Automatic opening and closing electric heating furnace manufacturer requires comprehensive consideration of many aspects. First of all, we should examine the strength of manufacturers, including production capacity, R&D team and industry experience. Strong manufacturers can better ensure product supply and innovation ability. Secondly, product quality is the key, and it is evaluated by product certification, material selection and manufacturing process to ensure the durability of products. Product performance can not be ignored, so we should choose manufacturers with matching technical parameters, rich types and customized services according to actual needs. After-sales service is equally important. Professional and timely service team, perfect after-sales content and extensive service network can make users worry about nothing. In addition, market reputation is also an important reference. We can understand the reputation and status of manufacturers through customer evaluation, industry reputation and award-winning honor. Finally, it is necessary to analyze the price and cost performance, and on the premise of ensuring the quality and performance, choose a manufacturer with reasonable price and high cost performance, so as to purchase Automatic opening and closing electric heating furnace products that meet the demand and have good cost performance.。

One-combustion energy saving

Automatic opening and closing electric heating furnacethe advantage is Simple operation, relatively simple Automatic opening and closing electric heating furnace operation, easy to realize automatic control, and helpful to improve production efficiency.、Environmental protection, energy saving, no pollutants generated by fuel combustion, in line with environmental protection requirements; At the same time, due to high thermal efficiency, energy consumption is relatively low.、The service life is long, and the key components such as furnace body and electric heating element are made of high quality materials, which has high durability and stability.、The temperature uniformity is good, and the temperature distribution in the Automatic opening and closing electric heating furnace is relatively uniform, which is helpful to reduce the temperature gradient in the heating process of the workpiece and improve the heating quality.、Long service life. The main parts of the Automatic opening and closing electric heating furnace, such as electric heating elements and furnace, are made of high-quality materials, which have high durability and stability and long service life.,is a Automatic opening and closing electric heating furnace,is a kind of high-temperature heating equipment with high efficiency, environmental protection and easy control.。

Related recommendation

-

What is a Trolley type preheating furnace? Introduction to the Working Principle of forging furnace

2025-5-27 -

Introduction to Isothermal multi well heating furnace and forging furnace advantages and features

2025-5-27 -

Introduction to Casting resistance heating furnace, introduction to Trolley resistance furnace advantages and characteristics

2025-5-27 -

What is a Medium temperature natural gas trolley furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Mold quenching resistance heating furnace and Trolley resistance furnace structure principle

2025-5-27 -

What is a Automatic feeding and discharging forging furnace? Introduction to the advantages and characteristics of the Forging furnace

2025-5-27 -

What is a Horizontal steel pipe heating furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27 -

Introduction to Dual car quenching furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

轨道燃气台车炉

2023-08-19 -

What is a SCR catalytic denitrification? How much is the price of the SCR denitration?

2025-5-27