Introduction to Energy saving resistance heating furnace, introduction to Trolley resistance furnace advantages and characteristics

Energy saving resistance heating furnaceis an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.,it can be used in fireproofing, pottery and porcelain, New material development, electron, building materials and other industries,The overall structural design is simple, diverse and beautiful.,it is usually composed of Temperature control system, furnace chamber, fire door, thermal insulation (material) and heating element,support customization。The following is to introduce the Energy saving resistance heating furnace:

1、Brief introduction of Energy saving resistance heating furnace

Energy saving resistance heating furnaceis a kind of high-temperature heating equipment with high efficiency, environmental protection and easy control.,is a kind of high quality and low price Energy saving resistance heating furnace,it is an ideal choice for customers to buy Energy saving resistance heating furnace。

Energy saving resistance heating furnace

2、Energy saving resistance heating furnace use

The purpose of Energy saving resistance heating furnace is introduced as follows:

- Metal melting and casting

- Metal heat treatment

- Ceramic and glass industries

- powder metallurgy

- New material development

Used for melting low melting point metals and alloys.

Such as quenching, normalizing, annealing, tempering, etc.

Used for baking and annealing of ceramics and glass.

Used for sintering and heat treatment of powder.

Used for synthesis and heat treatment of special materials and new materials.

Energy saving resistance heating furnace

3、Energy saving resistance heating furnace principle

Energy saving resistance heating furnacein the course of work,It is the thermal effect of current, that is, when current passes through a conductor with a certain resistance, electric energy will be converted into heat energy, which will make the resistor heat up and transfer heat to the materials in the furnace.,is a popular Energy saving resistance heating furnace,It can be used for Powder metallurgy sintering, Roasting and annealing of glass ceramics, Melting of low melting point metal, Heating before metal forging, anneal, Metal heat treatment heating and so on,it has the functions of Casting heating, anneal, normalizing, normalizing and quench,the product looks atmospheric.。

Energy saving resistance heating furnace

4、Energy saving resistance heating furnace function

Energy saving resistance heating furnaceit has the functions of Casting heating, Forging heating, hardening and tempering, anneal and temper,Mainly used foranneal,braze welding,Melting of low melting point metal,hardening and tempering andRoasting and annealing of glass ceramics,is a Energy saving resistance heating furnace,reliable quality,The price is relatively low.。

Energy saving resistance heating furnace

5、Energy saving resistance heating furnace price advantage

The Energy saving resistance heating furnace price is introduced as follows:

- Brand strength

- product function

- raw material

- product model

- market competition

At present, there are various brands of Energy saving resistance heating furnace in Shandong(Province). The performance, quality and after-sales of products under different brands are different, and the prices of Energy saving resistance heating furnace are different.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The quality of material selection is one of the main factors that directly affect the Energy saving resistance heating furnace. If the quality of material selection is better, the price may be more expensive. Therefore, customers must first understand the quality of material selection before purchasing products, and then compare whether the quality and price match.

Different models will have different specifications, which will lead to greater differences in the comprehensive configuration of products, which will also lead to greater changes in prices.

Market change is the main factor that affects the price level. Because of the instability and uncertainty of the market, the sales price of Energy saving resistance heating furnace will fluctuate greatly, and the market changes are various.

Energy saving resistance heating furnace

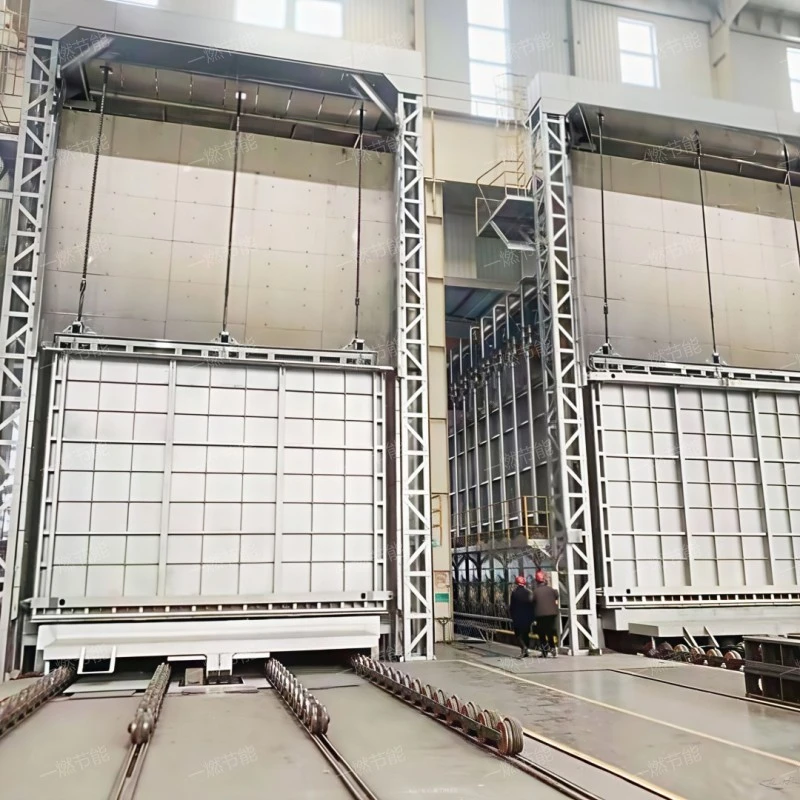

6、Real-time shooting in One-combustion energy saving's production workshop

The finished products of the Energy saving resistance heating furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Energy saving resistance heating furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Energy saving resistance heating furnaceWidely used in Heating before metal forging, quench, normalizing, anneal and braze welding,Simple operation, relatively simple Energy saving resistance heating furnace operation, easy to realize automatic control, and helpful to improve production efficiency.、The temperature control precision is high, and the Energy saving resistance heating furnace is equipped with advanced temperature control system, which can accurately control the temperature in the furnace and ensure the stability and reliability of the process.、The energy utilization rate is high, and the Energy saving resistance heating furnace has no heat loss caused by the exhaust gas of the fuel furnace in the working process, so the energy utilization rate is higher, which is helpful to save energy and reduce production costs.、High thermal efficiency, higher than traditional heating equipment such as flame furnace.、The electrothermal conversion efficiency is high, and the Energy saving resistance heating furnace can efficiently convert electric energy into heat energy, which is higher than the thermal efficiency of the traditional flame furnace.,Commonly used inRoasting and annealing of glass ceramics,normalizing,braze welding,quench,hardening and tempering and so on。

Related recommendation

-

What is a Medium temperature well tube furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Metal gas trolley furnace, forging furnace specifications, model parameters

2025-5-27 -

Introduction to Multi chamber roasting furnace, heating furnace specifications, model parameters

2025-5-27 -

What is a Rail car forging furnace? How much is the price of the heating furnace?

2025-5-27 -

Introduction to Car baking furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

What is a Full fiber heat treatment furnace? heating furnace specifications, models, and parameters

2025-5-27 -

What is a Full fiber trolley heating furnace? How much is the price of the heating furnace?

2025-5-27 -

Introduction to Catalytic reduction denitrification and SCR denitration structure principle

2025-5-27 -

What is a High temperature continuous quenching heat treatment furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

What is a Indirect heating heat treatment furnace? Introduction to the principle of Forging furnace structure

2025-5-27