Introduction to Resistance quenching furnace, introduction to Trolley resistance furnace advantages and characteristics

Resistance quenching furnaceis an industrial furnace that uses electric current to generate heat energy through resistive materials, thus heating workpieces or materials.,Widely used in Heating before metal forging, anneal, Roasting and annealing of glass ceramics, braze welding and quench,multifunctional, with functions such as Casting heating, normalizing, heat treatment, hardening and tempering and quench,it is an ideal choice for customers to buy Resistance quenching furnace。The following is to introduce the Resistance quenching furnace:

1、Brief introduction of Resistance quenching furnace

Resistance quenching furnaceis an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.,It can be used for Melting of low melting point metal, Heating before metal forging, normalizing, Powder metallurgy sintering, hardening and tempering, Metal heat treatment heating and so on,the product looks atmospheric.,is a common Resistance quenching furnace,Simple structure and reliable operation.,it is mainly composed of heating element, fire door, furnace chamber, furnace chamber and fire door。

Resistance quenching furnace

2、Resistance quenching furnace structure composition

The Resistance quenching furnace structure is introduced as follows:

- thermal insulation (material)

- Temperature control system

- furnace body

- base

- furnace shell

Thermal insulation materials are used to reduce heat loss and keep the temperature in the furnace stable. Commonly used thermal insulation materials include ceramic fibers, refractory fibers, etc. These materials have the characteristics of [commodity characteristics].

The temperature control system is used to accurately control the temperature in the furnace to meet different process requirements.

The furnace body is usually made of high-temperature and corrosion-resistant materials, such as high-quality steel plates, refractory bricks and ceramic fibers. These materials can withstand thermal stress and mechanical stress at high temperature, ensuring the stability and durability of the furnace body.

Used to support the whole Resistance quenching furnace and ensure its stability.

The furnace shell is usually made of steel plate for protection.

Resistance quenching furnace

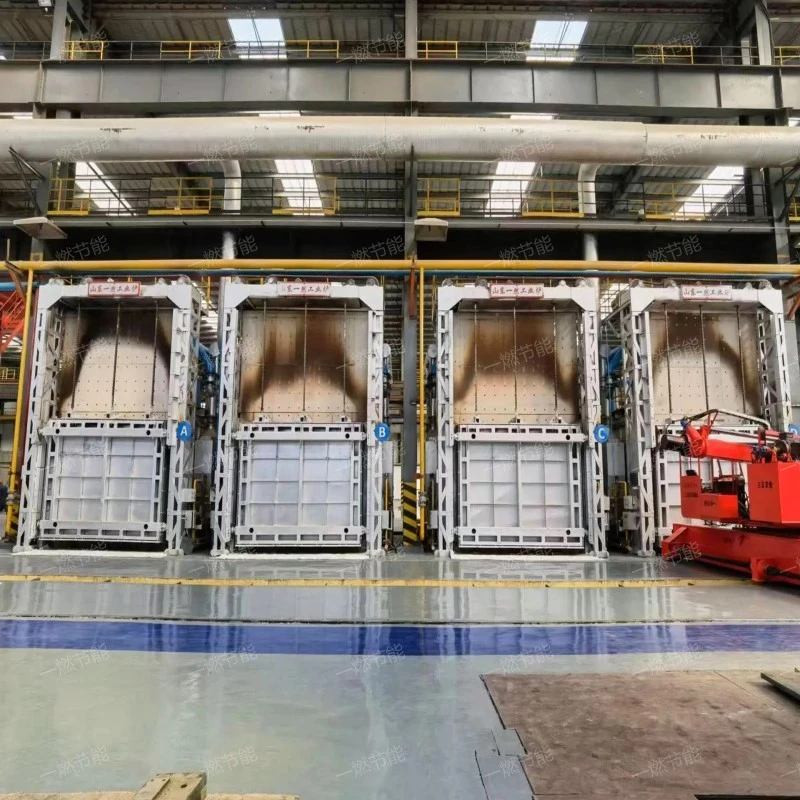

3、Resistance quenching furnace video live broadcast

Speak directly with facts on the spot。

Resistance quenching furnace

As you can see from the live video.,One-combustion energy saving widely used inNew material development,metallurgy,electron,fireproofing,electron and other industries。

4、Resistance quenching furnace principle

Resistance quenching furnaceat the start of the operation,It is the thermal effect of current, that is, when current passes through a conductor with a certain resistance, electric energy will be converted into heat energy, which will make the resistor heat up and transfer heat to the materials in the furnace.,it has the structure of Temperature control system, furnace shell, fire door, heating element and thermal insulation (material),is a popular Resistance quenching furnace,Widely used in braze welding, Melting of low melting point metal, Heating before metal forging, anneal and quench,the product looks beautiful.。

Resistance quenching furnace

5、Resistance quenching furnace use

The purpose of Resistance quenching furnace is introduced as follows:

- powder metallurgy

- Ceramic and glass industries

- Metal heat treatment

- Metal melting and casting

- New material development

Used for sintering and heat treatment of powder.

Used for baking and annealing of ceramics and glass.

Such as quenching, normalizing, annealing, tempering, etc.

Used for melting low melting point metals and alloys.

Used for synthesis and heat treatment of special materials and new materials.

Resistance quenching furnace

6、Resistance quenching furnace function

Resistance quenching furnacemultifunctional, with functions such as Casting heating, hardening and tempering, heat treatment, temper and normalizing,Commonly used innormalizing,Metal heat treatment heating,Roasting and annealing of glass ceramics,hardening and tempering,Powder metallurgy sintering and so on,the principle is simple.Thermal effect based on current. When current passes through resistive materials (such as resistance wires, resistance bands, etc.), due to the existence of resistance, electric energy will be converted into heat energy, which will make the resistive materials heat up. This heat is then transferred to the workpiece or material in the furnace to achieve the purpose of heating.。

Resistance quenching furnace

Resistance quenching furnacegenerally, it is composed of heating element, Temperature control system, thermal insulation (material), furnace shell, furnace chamber and other major components,This productThe overall structural design is simple, diverse and beautiful.,is an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.,Thermal effect based on current. When current passes through resistive materials (such as resistance wires, resistance bands, etc.), due to the existence of resistance, electric energy will be converted into heat energy, which will make the resistive materials heat up. This heat is then transferred to the workpiece or material in the furnace to achieve the purpose of heating.。

Related recommendation

-

Introduction to Double bridge trolley electric furnace and Trolley electric furnace advantages and features

2025-5-27 -

Introduction to Tubular quenching furnace and heating furnace working principle

2025-5-27 -

What is a Large chamber heating furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

Introduction to Chain heating furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

Introduction to Dual car industrial annealing furnace, how much is the price of the Forging furnace?

2025-5-27 -

Introduction to Gas walking furnace, forging furnace specifications, model parameters

2025-5-27 -

What is a Gas tube furnace? How much is the price of the forging furnace?

2025-5-27 -

What is a Trolley industrial furnace? Introduction to the advantages and characteristics of heating furnace functions

2025-5-27 -

Introduction to Deep well heat treatment furnace and Forging furnace advantages and features

2025-5-27 -

Introduction to Electric energy-saving industrial furnace, how much is the price of the Trolley electric heating furnace?

2025-5-27