What is a Three-stage gas heating furnace? Introduction to the principle of forging furnace structure

Three-stage gas heating furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,usually used in automobile, surface treatment, Household necessities, machinery, building materials and other fields,is developed and improved by One-combustion energy saving。

1、Brief introduction of Three-stage gas heating furnace

Three-stage gas heating furnaceIt is a forging heating device using gas as fuel.,It can be used for Metal heat treatment, Metal melting and casting, Metal forging heating, Improve production efficiency, Metal heat treatment, Metal tempering and so on,is a popular Three-stage gas heating furnace,widely used in Machinery manufacturing, shipping, material, petroleum, heat treatment and other fields,the product looks atmospheric.。

Three-stage gas heating furnace

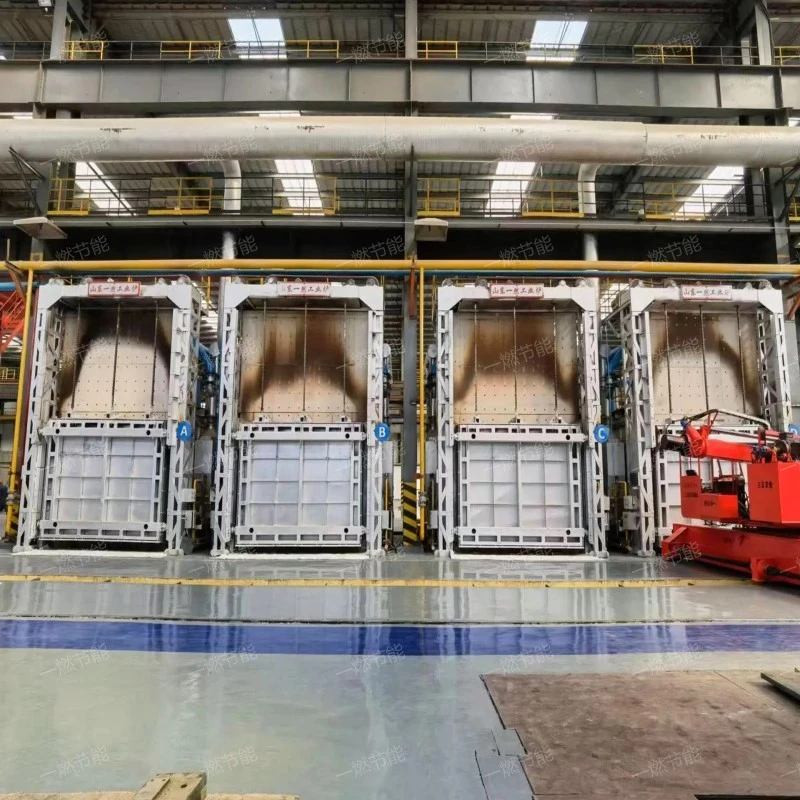

2、Three-stage gas heating furnace HD real picture

Three-stage gas heating furnace HD real shot, showing the product style.。

Three-stage gas heating furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Three-stage gas heating furnace application

Three-stage gas heating furnaces have the following purposes.

- Improve production efficiency

- Metal tempering

- Metal melting and casting

- Energy conservation and environmental protection

- Metal heat treatment

The Three-stage gas heating furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

By properly heating and cooling the metal material, the Three-stage gas heating furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

Although it is mainly used for forging heating, some types of Three-stage gas heating furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

The Three-stage gas heating furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

In addition to forging heating, Three-stage gas heating furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

Three-stage gas heating furnace

4、Three-stage gas heating furnace advantage

The advantages of Three-stage gas heating furnace are as follows:

- Uniform heating

- Wide application range

- Multiple fuel options

- clean energy

- easy to operate

The Three-stage gas heating furnace adopts regenerative combustion system or advanced burner design, which can realize uniform distribution of temperature in the furnace, ensure uniform heating of metal materials and improve product quality.

The Three-stage gas heating furnace is suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.

Although the Three-stage gas heating furnace mainly uses natural gas as fuel, some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.

Natural gas, as a clean energy source, produces less waste gas and dust after combustion, which has little pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.

The operation interface of the Three-stage gas heating furnace is friendly and easy for operators to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.

Three-stage gas heating furnace

5、Three-stage gas heating furnace principle

Three-stage gas heating furnaceat work,The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,it has the functions of Casting heating, hardening and tempering, Forging heating, normalizing and anneal,is a common Three-stage gas heating furnace,it can be used in electron, pharmacy, war industry, automobile, petroleum and other industries,has been favored by more and more customers.。

Three-stage gas heating furnace

6、One-combustion energy saving's strength

The company has many years of Three-stage gas heating furnace manufacturing experience, large scale and strong strength.。

One-combustion energy saving

Three-stage gas heating furnaceit is usually composed of recovery of waste heat, ventilation system, ventilation system, furnace chamber and Radiation chamber,This productThe structural design is more advanced and reasonable.,It is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.。

Related recommendation

-

What is a Double pass heating furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

What is a Pre embedded annealing heating furnace? Introduction to the advantages and characteristics of the Forging furnace

2025-5-27 -

调质台车锻造加热炉

2023-08-05 -

Introduction to Anchor chain industrial furnace, how much is the price of the Forging furnace?

2025-5-27 -

模具台车锻造加热炉

2023-09-16 -

Introduction to Top cylinder heating furnace, how much is the price of the Forging furnace?

2025-5-27 -

Introduction to Well type high-temperature quenching furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Resistance heating roasting furnace and Trolley resistance furnace structure principle

2025-5-27 -

Introduction to Multi tube bright annealing furnace, heating furnace specifications, model parameters

2025-5-27 -

What is a Low temperature trolley forging furnace? Introduction to the Working Principle of forging furnace

2025-5-27