Introduction to Staged roasting furnace and Forging furnace structure principle

Staged roasting furnaceIt is a forging heating device using gas as fuel.。

1、Brief introduction of Staged roasting furnace

Staged roasting furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,is developed and improved by One-combustion energy saving。

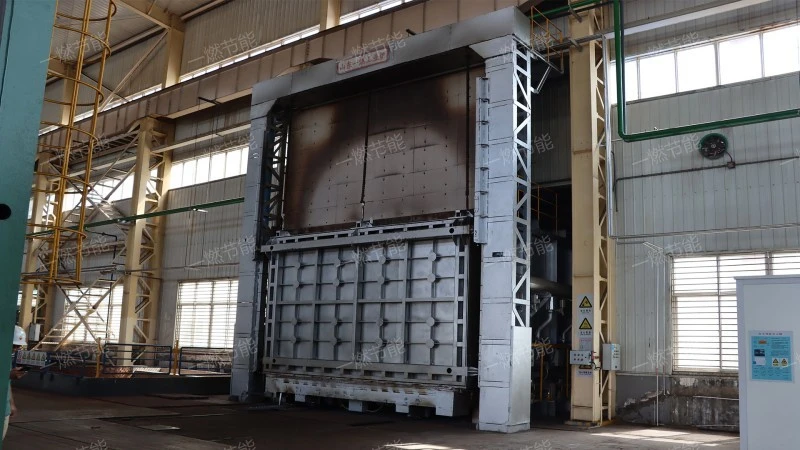

Staged roasting furnace

2、Working principle of Staged roasting furnace

Staged roasting furnaceat the start of the operation,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,The structure is novel, special, advanced, reasonable and scientific.,it is mainly composed of recovery of waste heat, Radiation chamber, furnace chamber, ventilation system and convection chamber,It is mostly used in Metal tempering, Improve production efficiency, Metal tempering, Metal forging heating, Energy conservation and environmental protection, Improve production efficiency and so on,features include Easy to maintain, Stable and reliable, Strong adaptability, Easy to control and Stable and reliable,be loved by our customers.。

Staged roasting furnace

3、Staged roasting furnace advantage

The advantages of Staged roasting furnace are as follows:

- Extend the service life of equipment

- Reduce operating costs

- Intelligent control

- easy to operate

- Efficient combustion

The Staged roasting furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The efficient combustion and waste heat recovery system of the Staged roasting furnace can significantly reduce energy consumption, thus reducing operating costs.

The Staged roasting furnace is usually equipped with an intelligent control system, which can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.

The operation interface of the Staged roasting furnace is friendly and easy for operators to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.

The Staged roasting furnace adopts advanced combustion technology and control system, which can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.

Staged roasting furnace

4、Staged roasting furnace structure composition

The Staged roasting furnace has the following structure

- combustor

- furnace chamber

- Radiation chamber

- ventilation system

- Waste heat recovery system

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

A space for holding metallic materials for heating.

The heat load of the main place for Staged roasting furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

Staged roasting furnace

5、How much is the Staged roasting furnace?

The Staged roasting furnace price is introduced as follows:

- product function

- marketing channel

- brand

- Configuration level

- region

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Each manufacturer's sales model is different, and the preferential degree of products is also different. Some manufacturers adopt the mode of "thin profit and quick turnover", and the price is relatively cheap. Some manufacturers sell their products at high prices to earn high profits. When purchasing products, they must compare the prices to avoid being cheated.

Different brands of products in the same series have more or less differences in product prices, and different brands of Staged roasting furnace have more or less differences in price.

Configuration refers to the hardware composition of the product, which mainly includes material selection, parts selection, etc. The higher the overall configuration of the product, the higher the price of the Staged roasting furnace, which is beyond doubt. One-combustion energy saving makes every product with great care in the attitude of being highly responsible to customers, so the price of One-combustion energy saving Staged roasting furnace is reasonable for products with the same configuration.

The consumption level will be different in different regions. When pricing equipment, many manufacturers often set the price according to the consumption level of the region. If the consumption level is high, the price will be correspondingly high, otherwise, the price will be very low.

Staged roasting furnace

6、One-combustion energy saving's after-sales service

Users should not only consider the quality, performance and price factors when buying Staged roasting furnace, but also consider the after-sales service of manufacturers. Good after-sales service can reduce many unnecessary troubles for customers. One-combustion energy saving manufacturers always adhere to the service attitude of "customer is God", implement high-standard and high-quality after-sales service attitude, conduct regular customer satisfaction surveys, and strictly supervise the quality of after-sales service, so as to relieve customers' purchase worries and make buyers completely worry-free.。

One-combustion energy saving

Staged roasting furnaceIt is a product series that integrates Metal heat treatment, Metal forging heating, Energy conservation and environmental protection, Metal melting and casting and Metal heat treatment,it is widely used inshipping,Household necessities,light industry,pharmacy,surface treatment and other industries。

Related recommendation

-

What is a Composite quenching furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

What is a Double head annealing heat treatment furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27 -

What is a Multi chamber rapid heating furnace? heating furnace specifications, models, and parameters

2025-5-27 -

Introduction to Kiln car trolley forging heating furnace, how much is the price of the Forging furnace?

2025-5-27 -

What is a Double chamber quenching heat treatment furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27 -

模具天然气台车炉

2023-09-17 -

Introduction to Full fiber forging heating electric furnace, Trolley electric furnace specifications, model parameters

2025-5-27 -

Introduction to Heating furnace denitrification and SCR denitration system structure principle

2025-5-27 -

Introduction to Resistance positive furnace, how much is the price of the Trolley electric heating furnace?

2025-5-27 -

What is a Medium temperature trolley resistance heating furnace? Introduction to the advantages and characteristics of the Trolley resistance heating furnace

2025-5-27