What is a Automatic temperature control through forging furnace? How much is the price of the heating furnace?

Automatic temperature control through forging furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,the advantage is Using regenerative combustion system or advanced burner design can realize the uniform distribution of temperature in the furnace, ensure the uniform heating of metal materials and improve product quality.、It can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、It can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.、Natural gas is mainly used as fuel, but some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.,The structure is novel, special, advanced, reasonable and scientific.,it is usually composed of furnace chamber, Radiation chamber, ventilation system, ventilation system and recovery of waste heat,is designed by One-combustion energy saving with advanced technology。The following is to introduce the Automatic temperature control through forging furnace:

1、Brief introduction of Automatic temperature control through forging furnace

Automatic temperature control through forging furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,The price is relatively low.,modern technology。

Automatic temperature control through forging furnace

2、Automatic temperature control through forging furnace function

Automatic temperature control through forging furnaceit has the functions of quench, hardening and tempering, anneal, normalizing and heat treatment,it has the characteristics of energy-efficient, Strong adaptability, energy saving and environmental protection, Easy to maintain and Stable and reliable,It has a wide range of uses, including Metal heat treatment, Metal forging heating, Improve production efficiency, Metal melting and casting and Metal melting and casting,at the start of the operation,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.,it is an ideal choice for customers to buy Automatic temperature control through forging furnace。

Automatic temperature control through forging furnace

3、Introduction of Automatic temperature control through forging furnace characteristics

Automatic temperature control through forging furnace has the following characteristics

- Stable and reliable

- Efficient heating

- energy saving and environmental protection

- Easy to control

- Easy to maintain

The Automatic temperature control through forging furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The Automatic temperature control through forging furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

As a clean energy source, gas produces less waste gas and waste smoke after combustion, which is beneficial to environmental protection. At the same time, some Automatic temperature control through forging furnaces are also equipped with waste heat recovery system, which further improves the energy utilization efficiency.

By adjusting the burner and ventilation system, the temperature and atmosphere in the furnace can be accurately controlled to meet the heating requirements of different metal materials.

The structural design of the Automatic temperature control through forging furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

Automatic temperature control through forging furnace

4、Structural advantages of Automatic temperature control through forging furnace

The Automatic temperature control through forging furnace has the following structure

- Radiation chamber

- convection chamber

- Waste heat recovery system

- furnace chamber

- Radiation chamber

The heat load of the main place for Automatic temperature control through forging furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

Used to recover the exhaust heat of the heating furnace. There are two kinds of recovery methods, one is to recover by preheating combustion air, so that the recovered heat can return to the furnace again; The other is to use another recovery system to recover heat. The former is called air preheating mode, and the latter is usually called waste heat boiler mode.

A space for holding metallic materials for heating.

The heat load of the main place for Automatic temperature control through forging furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Automatic temperature control through forging furnace

5、Automatic temperature control through forging furnace price advantage

The Automatic temperature control through forging furnace price is introduced as follows:

- Product technology

- Self quality

- Manufacturer's sales model

- market quotation

- product model

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

Quality generally refers to the quality of the product. The better the quality, the higher the quality of the product. Because the quality is directly proportional to the cost of the product, the price of the Automatic temperature control through forging furnace will vary greatly. One-combustion energy saving attaches great importance to the quality of products, and the formulation of prices is also reasonable.

Direct-selling manufacturers are cheaper than second-and third-tier dealers because the former earns the difference without going through middlemen; Online sales are cheaper than offline sales, because you need to invest in store fees, employee fees and other related expenses in the later stage; Close-distance sales are cheaper than long-distance sales because the latter consumes a lot of transportation costs.

If there is a large demand for Automatic temperature control through forging furnace in the market, the price of Automatic temperature control through forging furnace will naturally become higher. On the contrary, if the supply of this product exceeds demand, then manufacturers will have inventory accumulation. In order to dispose of these products as soon as possible, some manufacturers will sell them by lowering the price of products, so the price will become lower.

There are many specifications and models of Automatic temperature control through forging furnace in the market now. Under normal circumstances, the price of large-sized Automatic temperature control through forging furnace is definitely higher than that of small-sized Automatic temperature control through forging furnace.

Automatic temperature control through forging furnace

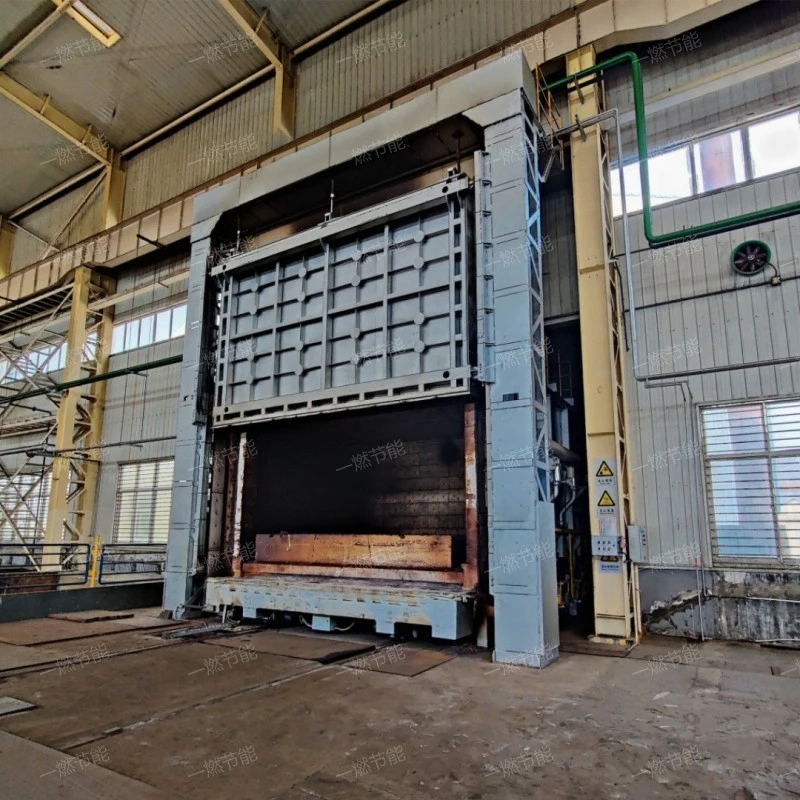

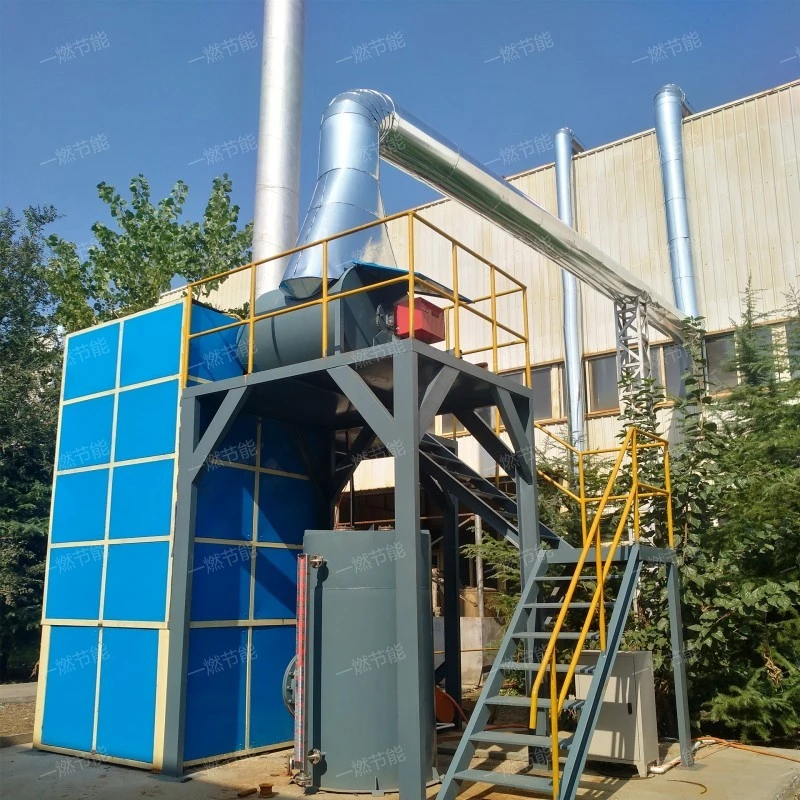

6、High-definition picture display of One-combustion energy saving workshop

The finished products of the Automatic temperature control through forging furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Automatic temperature control through forging furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Automatic temperature control through forging furnacefeatures include Stable and reliable, Easy to control, Stable and reliable, Easy to maintain and energy saving and environmental protection,widely used inchemical industry,heat treatment,Household necessities,metallurgy,Machinery manufacturing and other industries,is a popular Automatic temperature control through forging furnace。

Related recommendation

-

Introduction to Automatic temperature control through heating furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

回火台车炉

2023-08-26 -

What is a Energy saving and environmentally friendly chain grate furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

What is a Profile heating furnace? Forging furnace specifications, models, and parameters

2025-5-27 -

What is a Quenching and tempering annealing heat treatment furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

Introduction to Long bar material heating furnace, how much is the price of the Forging furnace?

2025-5-27 -

What is a Trolley circulating furnace? Introduction to the Working Principle of forging furnace

2025-5-27 -

Introduction to Low temperature tempering resistance heating furnace, advantages, characteristics and principles of Trolley resistance heating furnace

2025-5-27 -

Introduction to Energy saving roller bottom furnace and Forging furnace structure principle

2025-5-27 -

Introduction to Catalytic flue gas denitrification system, how much is the price of the SCR denitration?

2025-5-27