What is a Chain type iron core annealing furnace? heating furnace specifications, models, and parameters

Chain type iron core annealing furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,It has a wide range of uses, and is often used inMetal melting and casting,Metal forging heating,Metal heat treatment,Metal tempering,Metal melting and casting and so on,it has the characteristics of energy saving and environmental protection, energy-efficient, Stable and reliable, Easy to maintain and Strong adaptability,it is an ideal choice for customers to buy Chain type iron core annealing furnace。The following is to introduce the Chain type iron core annealing furnace:

1、Brief introduction of Chain type iron core annealing furnace

Chain type iron core annealing furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,usually used in light industry, petroleum, electron, chemical industry, heat treatment and other fields,at work,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.。

Chain type iron core annealing furnace

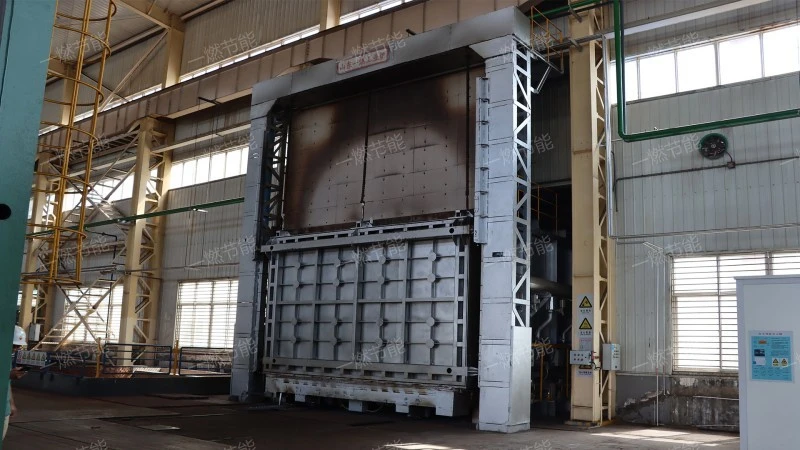

2、Chain type iron core annealing furnace real beat

The beauty of Chain type iron core annealing furnace comes from the detail design.。

Chain type iron core annealing furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Advantages of Chain type iron core annealing furnace principle

Chain type iron core annealing furnaceThe high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,It is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,the main structure includes combustor, convection chamber, ventilation system, Radiation chamber, ventilation system and so on,Chain type iron core annealing furnaceThe overall structural design is relatively simple。

Chain type iron core annealing furnace

4、Video analysis of Chain type iron core annealing furnace

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Chain type iron core annealing furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd It is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.。

5、Introduction of Chain type iron core annealing furnace characteristics

Chain type iron core annealing furnace has the following characteristics

- Easy to maintain

- Stable and reliable

- Easy to maintain

- Efficient heating

- Strong adaptability

The structural design of the Chain type iron core annealing furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The Chain type iron core annealing furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The structural design of the Chain type iron core annealing furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The Chain type iron core annealing furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

The Chain type iron core annealing furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

Chain type iron core annealing furnace

6、Chain type iron core annealing furnace price

The Chain type iron core annealing furnace price is introduced as follows:

- Reasonable sales model

- Low cost of raw materials

- brand

- technology

- select a qualified person

Direct-selling manufacturers are cheaper than second-and third-tier dealers because the former earns the difference without going through middlemen; Online sales are cheaper than offline sales, because you need to invest in store fees, employee fees and other related expenses in the later stage; Close-distance sales are cheaper than long-distance sales because the latter consumes a lot of transportation costs.

Production costs include raw material costs, labor costs, other costs, etc., which manufacturers need to invest when producing products, but these factors are not certain. They are affected by the market. When one factor in the market changes, the production costs of manufacturers will also change, and the price of Chain type iron core annealing furnace will also fluctuate to some extent.

Different brands of products in the same series have more or less differences in product prices, and different brands of Chain type iron core annealing furnace have more or less differences in price.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

The quality of material selection is one of the main factors that directly affect the Chain type iron core annealing furnace. If the quality of material selection is better, the price may be more expensive. Therefore, customers must first understand the quality of material selection before purchasing products, and then compare whether the quality and price match.

Chain type iron core annealing furnace

Chain type iron core annealing furnacemultifunctional, with functions such as hardening and tempering, Forging heating, temper, quench and Casting heating,it has been widely used in material, Household necessities, heat treatment, automobile, petroleum and other industries,Widely used inEnergy conservation and environmental protection,Improve production efficiency,Metal forging heating,Metal tempering,Metal heat treatment and so on。

Related recommendation

-

What is a Natural gas thermal storage tubular roaster? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

Introduction to Normalizing trolley forging heating furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Gas through forging furnace, how much is the price of the heating furnace?

2025-5-27 -

Introduction to SCR low temperature flue gas denitrification equipment, SCR denitration specifications, model parameters

2025-5-27 -

Introduction to Gas storage chain annealing furnace and Forging furnace advantages and features

2025-5-27 -

What is a Casting forging furnace? How much is the price of the heating furnace?

2025-5-27 -

Introduction to Regenerative burner roller furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

Introduction to Automatic entry and exit of heating furnace and heating furnace advantages and features

2025-5-27 -

Introduction to Regenerative burner trolley forging heating furnace and forging furnace working principle

2025-5-27 -

Introduction to End in end out step heating furnace, introduction to forging furnace function advantages and characteristics

2025-5-27