Introduction to High temperature SCR denitration system and SCR denitration system structure principle

High temperature SCR denitration systemthe full name is selective catalytic reduction technology, which is an advanced flue gas denitrification technology.,the product looks beautiful.,features include Mature technology, Strong adaptability, Strong adaptability, Promote sustainable development and Economically feasible,it is an ideal choice for customers to buy High temperature SCR denitration system。

1、Brief introduction of High temperature SCR denitration system

High temperature SCR denitration systemthat is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.。

High temperature SCR denitration system

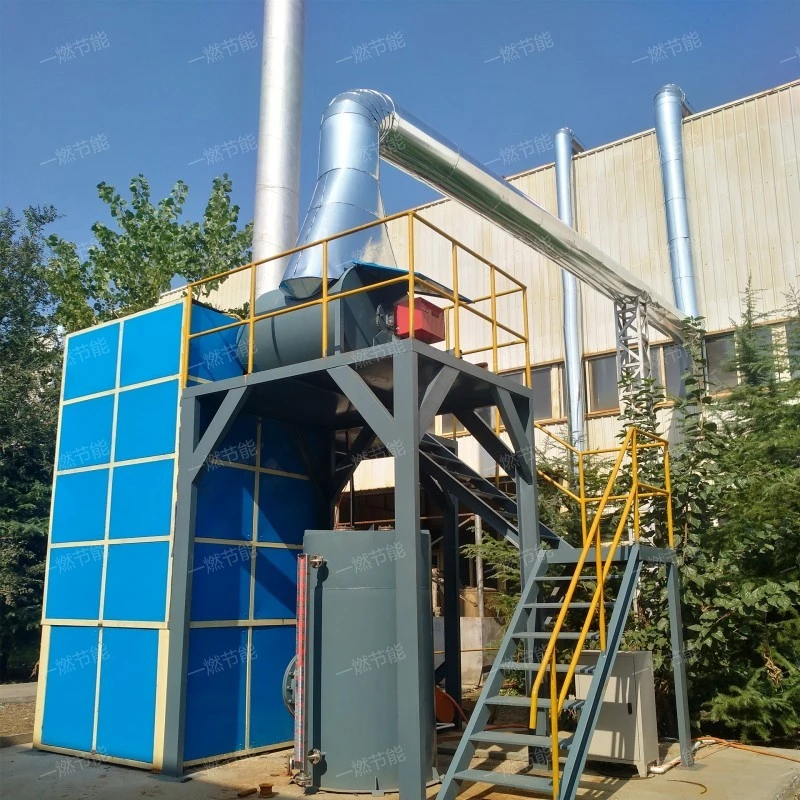

2、High temperature SCR denitration system customer scene picture

High temperature SCR denitration system styles and designs are diverse, specifications and models can be customized according to customer needs, providing high-definition pictures for new and old customers' reference.。

High temperature SCR denitration system

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、High temperature SCR denitration system function

High temperature SCR denitration systemit has the functions of Promote sustainable development, environmental protection, Improve energy efficiency, Improve working conditions and Promote sustainable development,has been favored by more and more customers.。

High temperature SCR denitration system

4、High temperature SCR denitration system use

High temperature SCR denitration systemIt has a wide range of uses, including Meet the requirements of environmental protection, Promote sustainable development, Improve product quality, Meet the requirements of environmental protection and environmental protection,is carefully developed by One-combustion energy saving combined with advanced technology。

High temperature SCR denitration system

5、High temperature SCR denitration system HD real shot

On-site aerial photography of High temperature SCR denitration system。

High temperature SCR denitration system

As you can see from the live video.,One-combustion energy saving the product looks atmospheric.。

6、High temperature SCR denitration system price concessions

The High temperature SCR denitration system price is introduced as follows:

- product function

- marketing channel

- product costs

- Model size

- raw material

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

One-combustion energy saving has long used the sales method of small profits but quick turnover to sell products, and the product price, market price and ex-factory price are the same. The purpose of this is to improve the sales volume of products and the visibility of enterprises.

A High temperature SCR denitration system needs to spend a lot of manufacturing costs from research and development to production to sales, including raw material costs, technical costs, labor costs, etc. The higher the manufacturing cost, the higher the price will be.

Because there are many specifications and models of High temperature SCR denitration system, the quotations of High temperature SCR denitration system with different specifications and models are different.

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

High temperature SCR denitration system

High temperature SCR denitration systemit is widely used incement plant,cement plant,iron and steel plant,metallurgy,building materials and other industries,at the start of the operation,Ammonia gas or other suitable reducing agent (such as urea aqueous solution) is sprayed into the flue gas upstream of the catalyst at high temperature. Under the action of catalyst, the reducing agent selectively reacts with nitrogen oxides (NOx) in flue gas to generate pollution-free nitrogen and water vapor. Because NH3 is selective, it only reacts with NOx and basically does not react with O2, so this technology is called selective catalytic reduction denitrification.。

Related recommendation

-

What is a Well type trolley furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

Introduction to Fully automatic heating furnace and forging furnace advantages and features

2025-5-27 -

Introduction to Regenerative natural gas step heat treatment furnace and forging furnace advantages and features

2025-5-27 -

Introduction to Off furnace denitrification, advantages, characteristics and principles of SCR denitration system

2025-5-27 -

Introduction to Catalytic flue gas denitrification system, how much is the price of the SCR denitration?

2025-5-27 -

What is a Industrial quenching furnace denitrification? Introduction to the Working Principle of SCR denitration system

2025-5-27 -

What is a Regenerative gas chain annealing furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

What is a SCR flue gas catalytic denitrification equipment? Introduction to the principle of SCR flue gas denitrification structure

2025-5-27 -

Introduction to Split flow forging furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

Introduction to Heat treatment resistance heating furnace, introduction to Trolley resistance furnace advantages and characteristics

2025-5-27