Introduction to Low temperature catalytic flue gas denitrification system, SCR denitration specifications, model parameters

Low temperature catalytic flue gas denitrification systemis an efficient, stable and environment-friendly flue gas denitrification technology.,has been favored by more and more customers.。The following is to introduce the Low temperature catalytic flue gas denitrification system:

1、Brief introduction of Low temperature catalytic flue gas denitrification system

Low temperature catalytic flue gas denitrification systemit refers to the process of removing nitrogen oxides from flue gas to reduce environmental pollution. NOx is a pollutant harmful to the atmospheric environment, which has strong irritation and toxicity, and will lead to environmental problems such as acid rain and photochemical smog, and also endanger human health. The main principle of flue gas denitrification technology is to reduce NOx to nitrogen and water by adding appropriate reducing agent or catalyst in the combustion process or flue gas treatment system, so as to reduce NOx emission.,Ammonia gas or other suitable reducing agent (such as urea aqueous solution) is sprayed into the flue gas upstream of the catalyst at high temperature. Under the action of catalyst, the reducing agent selectively reacts with nitrogen oxides (NOx) in flue gas to generate pollution-free nitrogen and water vapor. Because NH3 is selective, it only reacts with NOx and basically does not react with O2, so this technology is called selective catalytic reduction denitrification.,usually used in Gas power plant, iron and steel plant, coal-fired power station, Gas power plant, cement plant and other fields,multifunctional, with functions such as Promote sustainable development, Improve working conditions, Promote sustainable development, environmental protection and Improve energy efficiency,is a kind of Low temperature catalytic flue gas denitrification system manufactured by One-combustion energy saving。

Low temperature catalytic flue gas denitrification system

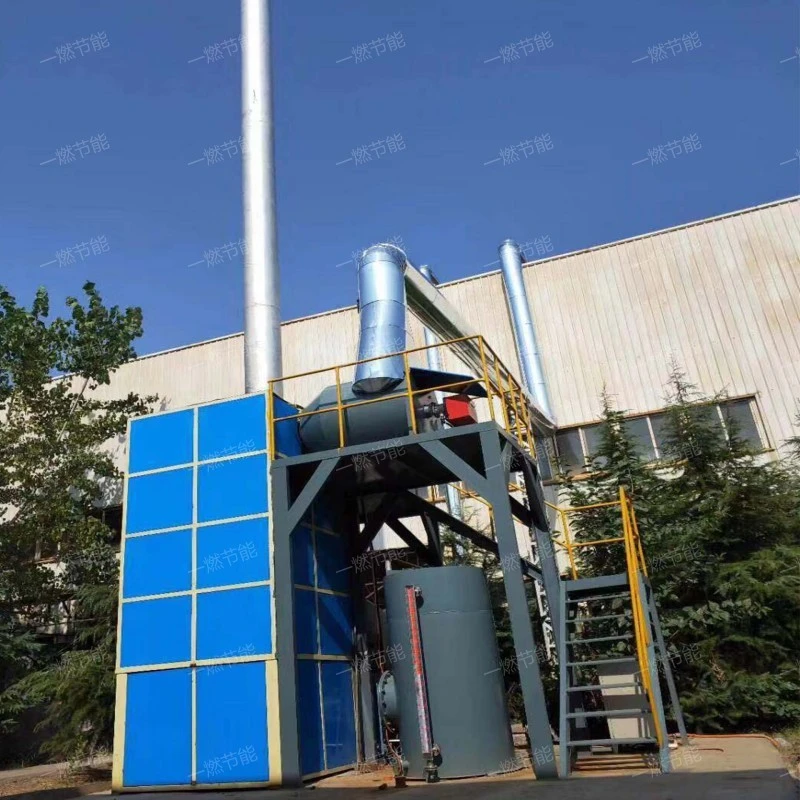

2、Low temperature catalytic flue gas denitrification system field real shot

On-site aerial photography of Low temperature catalytic flue gas denitrification system。

Low temperature catalytic flue gas denitrification system

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd the product looks atmospheric.。

3、Low temperature catalytic flue gas denitrification system HD picture real shot

There are many specifications and models of Low temperature catalytic flue gas denitrification system, which can be selected by users at will. The high-definition factory map is available for our customers to visit.。

Low temperature catalytic flue gas denitrification system

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

4、Low temperature catalytic flue gas denitrification system application

Low temperature catalytic flue gas denitrification systemCommonly used inFlue gas denitrification,Improve product quality,Promote sustainable development,Promote sustainable development,Improve product quality and so on,at the start of the operation,Ammonia gas or other suitable reducing agent (such as urea aqueous solution) is sprayed into the flue gas upstream of the catalyst at high temperature. Under the action of catalyst, the reducing agent selectively reacts with nitrogen oxides (NOx) in flue gas to generate pollution-free nitrogen and water vapor. Because NH3 is selective, it only reacts with NOx and basically does not react with O2, so this technology is called selective catalytic reduction denitrification.。

Low temperature catalytic flue gas denitrification system

5、Low temperature catalytic flue gas denitrification system price advantage

The Low temperature catalytic flue gas denitrification system price is introduced as follows:

- market demand

- After-sales service level

- Low cost of raw materials

- mass discrepancy

- select a qualified person

The market demand has a certain impact on the price of Low temperature catalytic flue gas denitrification system. When there are many customers who need Low temperature catalytic flue gas denitrification system in the market, there will be a phenomenon that demand exceeds supply, and then the price of Low temperature catalytic flue gas denitrification system will become higher. On the contrary, when there are very few customers who need Low temperature catalytic flue gas denitrification system, there will be a phenomenon of oversupply, and the price of Low temperature catalytic flue gas denitrification system will be reduced.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Low temperature catalytic flue gas denitrification system price and service can meet the actual needs of customers.

The production cost determines the price. The production cost here mainly includes technology, materials, technology, manpower and other related factors, among which the technology content is high, and the cost is relatively high, but the performance will be better; The better the quality of raw materials, the greater the cost and the longer the overall life of the product; If the manufacturer has a rational manufacturing process and strict production management system, and can make full use of human and material resources, then it can reduce the waste of expenses and production costs to a great extent, and the Low temperature catalytic flue gas denitrification system just meets this condition, so as to ensure the high-tech content and high quality of products, it can also enjoy low prices.

The selling price of excellent quality products is also high, so customers should also consider the quality and price of products comprehensively in the process of purchasing products, so as to buy products with high cost performance.

The raw materials used by manufacturers of different products will definitely be different. Some manufacturers use good raw materials for processing, and the cost of producing and manufacturing products is definitely high. If the quality of products produced by manufacturers is not guaranteed and the materials used are not very good, then the production cost of products will be low, and the price will be very low.

Low temperature catalytic flue gas denitrification system

6、High-definition picture display of One-combustion energy saving workshop

The finished products of the Low temperature catalytic flue gas denitrification system factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Low temperature catalytic flue gas denitrification system factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Low temperature catalytic flue gas denitrification systemit has been widely used in building materials, iron and steel plant, metallurgy, coal-fired power station, Gas power plant and other industries,at work,Catalysts are used to promote the selective catalytic reduction reaction between reducing agents (such as ammonia and urea) and NOx in flue gas. Under the action of catalyst, the reductant preferentially reacts with NOx to generate harmless nitrogen and water vapor, but hardly reacts with oxygen in flue gas. This chemical reaction is usually carried out in the temperature range of 200-450℃, and the specific reaction temperature depends on the type of catalyst selected.,The structural design is more advanced and reasonable.,it mainly includes Temperature control and monitoring system, Flue gas mixing and distribution system, Catalyst reactor, Catalyst supply system and control system。

Related recommendation

-

What is a Automatic quenching heat treatment furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27 -

Introduction to Double chamber annealing furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Resistance heating roasting furnace and Trolley resistance furnace structure principle

2025-5-27 -

What is a Fully automatic step-by-step heat treatment furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

What is a Aluminum shell heating furnace? Introduction to the advantages and characteristics of heating furnace functions

2025-5-27 -

What is a Trolley high-temperature furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

Introduction to SCR oxidation denitrification equipment, how much is the price of the SCR flue gas denitrification?

2025-5-27 -

What is a Energy saving and environmentally friendly tube furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

Introduction to Regenerative gas roller bottom furnace and Forging furnace advantages and features

2025-5-27 -

What is a Resistance heating energy-saving industrial furnace? Introduction to the advantages and characteristics of Trolley resistance furnace functions

2025-5-27