Introduction to Denitrification system for steel plant heating furnace, introduction to SCR flue gas denitrification advantages and characteristics

Denitrification system for steel plant heating furnacethe full name is selective catalytic reduction technology, which is an advanced flue gas denitrification technology.,is a kind of Denitrification system for steel plant heating furnace manufactured by One-combustion energy saving。The following is to introduce the Denitrification system for steel plant heating furnace:

1、Brief introduction of Denitrification system for steel plant heating furnace

Denitrification system for steel plant heating furnaceis an efficient, stable and environment-friendly flue gas denitrification technology.,Widely used inFlue gas denitrification,environmental protection,Meet the requirements of environmental protection,Meet the requirements of environmental protection,Promote sustainable development and so on,at the start of the operation,Catalysts are used to promote the selective catalytic reduction reaction between reducing agents (such as ammonia and urea) and NOx in flue gas. Under the action of catalyst, the reductant preferentially reacts with NOx to generate harmless nitrogen and water vapor, but hardly reacts with oxygen in flue gas. This chemical reaction is usually carried out in the temperature range of 200-450℃, and the specific reaction temperature depends on the type of catalyst selected.。

Denitrification system for steel plant heating furnace

2、Advantages of Denitrification system for steel plant heating furnace principle

Denitrification system for steel plant heating furnacein the course of work,Catalysts are used to promote the selective catalytic reduction reaction between reducing agents (such as ammonia and urea) and NOx in flue gas. Under the action of catalyst, the reductant preferentially reacts with NOx to generate harmless nitrogen and water vapor, but hardly reacts with oxygen in flue gas. This chemical reaction is usually carried out in the temperature range of 200-450℃, and the specific reaction temperature depends on the type of catalyst selected.,is an advanced Denitrification system for steel plant heating furnace developed by our company in combination with the actual situation of the industry。

Denitrification system for steel plant heating furnace

3、Denitrification system for steel plant heating furnace use

Denitrification system for steel plant heating furnaceIt is a product series that integrates environmental protection, Improve product quality, Flue gas denitrification, Meet the requirements of environmental protection and Improve product quality,it is an ideal choice for customers to buy Denitrification system for steel plant heating furnace。

Denitrification system for steel plant heating furnace

4、Denitrification system for steel plant heating furnace use

Denitrification system for steel plant heating furnaceCommonly used inPromote sustainable development,Flue gas denitrification,environmental protection,Improve product quality,Meet the requirements of environmental protection and so on。

Denitrification system for steel plant heating furnace

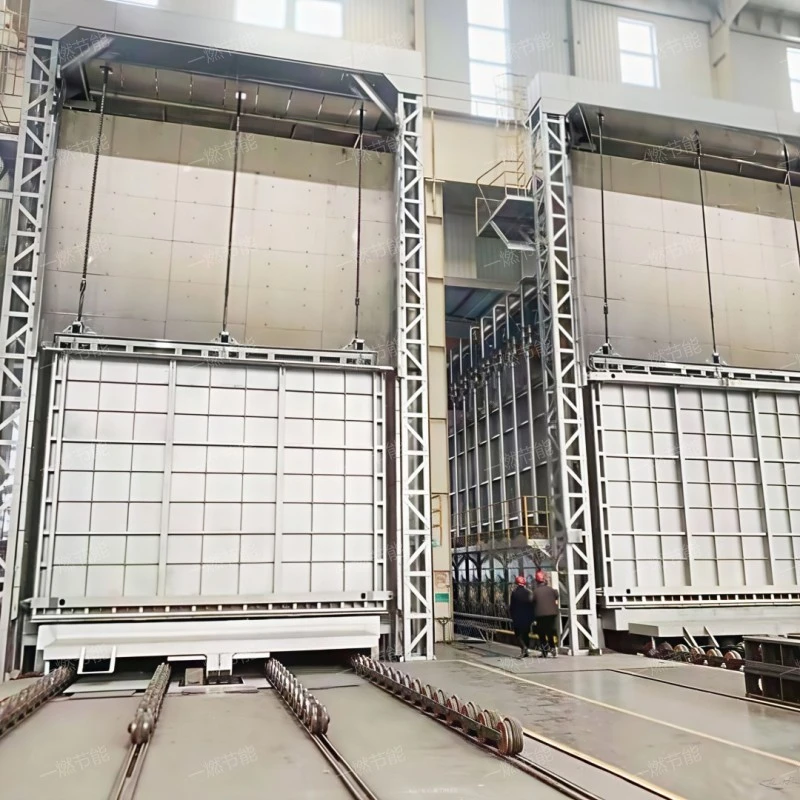

5、Denitrification system for steel plant heating furnace HD picture

Provide high-definition Denitrification system for steel plant heating furnace real shot, a variety of specifications and models for customers to visit.。

Denitrification system for steel plant heating furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

Denitrification system for steel plant heating furnaceit has the functions of Improve working conditions, Improve energy efficiency, environmental protection, Improve working conditions and Promote sustainable development,that is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.,It has a wide range of uses, and is often used inFlue gas denitrification,Promote sustainable development,environmental protection,Improve product quality,Meet the requirements of environmental protection and so on。

Related recommendation

-

Introduction to Side entry and side exit step heat treatment furnace and heating furnace advantages and features

2025-5-27 -

What is a Bright Annealing Electric Furnace? Introduction to the advantages, characteristics, and principles of the Trolley electric heating furnace

2025-5-27 -

What is a Bright well quenching furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

Introduction to Split type quenching heating furnace and forging furnace advantages and features

2025-5-27 -

Introduction to Regenerative through forging furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

What is a Large roller hearth furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

Introduction to Leaf spring heating furnace and Forging furnace working principle

2025-5-27 -

Introduction to Protective gas natural gas trolley furnace and heating furnace structure principle

2025-5-27 -

Introduction to Side outlet heating furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

What is a Split type quenching industrial furnace? How much is the price of the heating furnace?

2025-5-27