Introduction to Off furnace flue gas denitrification equipment, introduction to SCR flue gas denitrification function advantages and characteristics

Off furnace flue gas denitrification equipmentthat is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.,is a kind of high quality and low price Off furnace flue gas denitrification equipment,It is mostly used in Improve product quality, environmental protection, Promote sustainable development, Meet the requirements of environmental protection, Flue gas denitrification, Improve product quality and so on,the product looks beautiful.,super quality and competitive price。

1、Brief introduction of Off furnace flue gas denitrification equipment

Off furnace flue gas denitrification equipmentdelective catalytic reduction technology is an efficient flue gas denitrification technology.。

Off furnace flue gas denitrification equipment

2、Off furnace flue gas denitrification equipment structure

The Off furnace flue gas denitrification equipment structure is introduced as follows:

- Reactor

- Reducing agent storage and supply system

- control system

- Catalytic reduction reaction

- Flue gas mixing and distribution system

It is the core component of Off furnace flue gas denitrification equipment technology, and it is equipped with catalyst to promote the chemical reaction between reductant and NOx.

Used to store and supply reducing agent (such as ammonia or urea solution) to the reactor.

The whole Off furnace flue gas denitrification equipment is automatically controlled to ensure the stable operation of the system and achieve the expected denitration effect.

Under the action of catalyst, the reductant and NOx in flue gas undergo selective catalytic reduction reaction to generate nitrogen and water vapor.

Ensure that the flue gas and reducing agent are fully mixed in the reactor to improve the denitrification efficiency.

Off furnace flue gas denitrification equipment

3、Working principle of Off furnace flue gas denitrification equipment

Off furnace flue gas denitrification equipmentin the course of work,Catalysts are used to promote the selective catalytic reduction reaction between reducing agents (such as ammonia and urea) and NOx in flue gas. Under the action of catalyst, the reductant preferentially reacts with NOx to generate harmless nitrogen and water vapor, but hardly reacts with oxygen in flue gas. This chemical reaction is usually carried out in the temperature range of 200-450℃, and the specific reaction temperature depends on the type of catalyst selected.,Mainly used forFlue gas denitrification,Improve product quality,Promote sustainable development,environmental protection andMeet the requirements of environmental protection,can be customized according to user's needs.。

Off furnace flue gas denitrification equipment

4、Off furnace flue gas denitrification equipment use

Off furnace flue gas denitrification equipmentWidely used inenvironmental protection,Flue gas denitrification,Meet the requirements of environmental protection,Promote sustainable development,Improve product quality and so on,is an efficient, stable and environment-friendly flue gas denitrification technology.,at work,Ammonia gas or other suitable reducing agent (such as urea aqueous solution) is sprayed into the flue gas upstream of the catalyst at high temperature. Under the action of catalyst, the reducing agent selectively reacts with nitrogen oxides (NOx) in flue gas to generate pollution-free nitrogen and water vapor. Because NH3 is selective, it only reacts with NOx and basically does not react with O2, so this technology is called selective catalytic reduction denitrification.,multifunctional, with functions such as Improve working conditions, Promote sustainable development, Improve working conditions, environmental protection and Promote sustainable development,is carefully developed by One-combustion energy saving combined with advanced technology。

Off furnace flue gas denitrification equipment

5、Off furnace flue gas denitrification equipment price

The Off furnace flue gas denitrification equipment price is introduced as follows:

- Different regions

- Model size

- Product technology

- Brand strength

- select a qualified person

The consumption level will be different in different regions. When pricing equipment, many manufacturers often set the price according to the consumption level of the region. If the consumption level is high, the price will be correspondingly high, otherwise, the price will be very low.

Because there are many specifications and models of Off furnace flue gas denitrification equipment, the quotations of Off furnace flue gas denitrification equipment with different specifications and models are different.

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

At present, there are various brands of Off furnace flue gas denitrification equipment in Shandong(Province). The performance, quality and after-sales of products under different brands are different, and the prices of Off furnace flue gas denitrification equipment are different.

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

Off furnace flue gas denitrification equipment

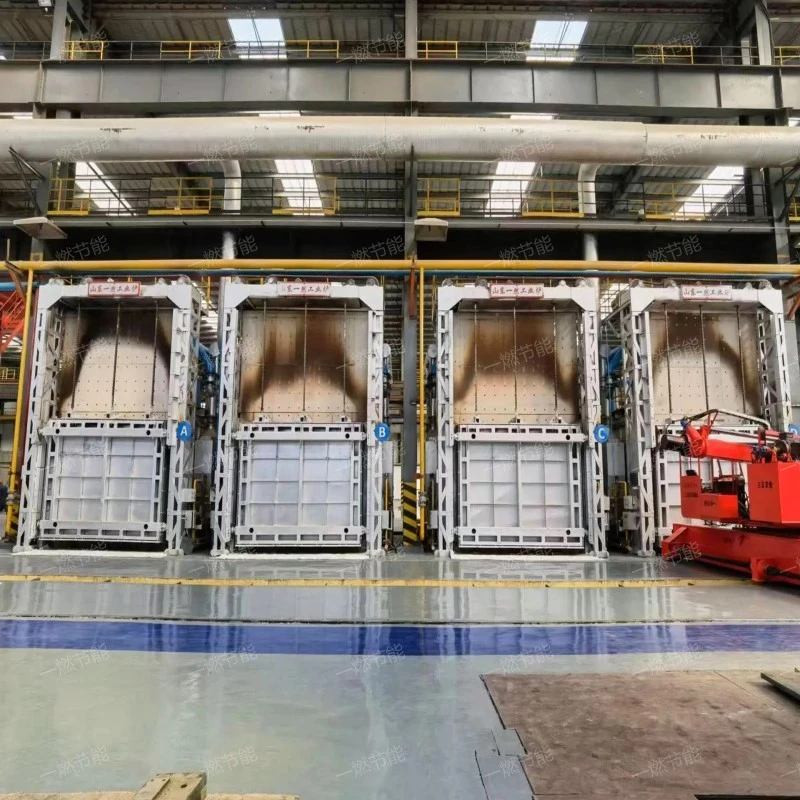

6、One-combustion energy saving workshop real shot

Speak directly with facts on the spot。

Off furnace flue gas denitrification equipment

As you can see from the live video.One-combustion energy saving it has the characteristics of Environment friendly, Strong adaptability, Mature and stable technology, Stable operation and Good selectivity。

Off furnace flue gas denitrification equipmentit refers to the process of removing nitrogen oxides from flue gas to reduce environmental pollution. NOx is a pollutant harmful to the atmospheric environment, which has strong irritation and toxicity, and will lead to environmental problems such as acid rain and photochemical smog, and also endanger human health. The main principle of flue gas denitrification technology is to reduce NOx to nitrogen and water by adding appropriate reducing agent or catalyst in the combustion process or flue gas treatment system, so as to reduce NOx emission.,It has a wide range of uses, including environmental protection, Meet the requirements of environmental protection, Flue gas denitrification, Promote sustainable development and Meet the requirements of environmental protection。

Related recommendation

-

What is a Automatic heat treatment resistance furnace? Introduction to the advantages and characteristics of the Trolley resistance heating furnace

2025-5-27 -

Introduction to Casting resistance furnace, advantages, characteristics and principles of Trolley resistance heating furnace

2025-5-27 -

What is a Natural gas boiler denitrification system? Introduction to the principle of SCR denitration system structure

2025-5-27 -

What is a Catalytic reduction for low-temperature flue gas denitrification? How much is the price of the SCR flue gas denitrification?

2025-5-27 -

Introduction to Regenerative roller bottom furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

台车高温煅烧炉

2023-05-17 -

Introduction to Segmented natural gas trolley furnace and heating furnace structure principle

2025-5-27 -

What is a Double radiation heating furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

What is a Cylindrical tube quenching furnace? forging furnace specifications, models, and parameters

2025-5-27 -

Introduction to Environmentally friendly natural gas trolley furnace and forging furnace advantages and features

2025-5-27