Brief introduction and functional advantages of Segmented annealing heat treatment furnace

Segmented annealing heat treatment furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.。The following is to introduce the Segmented annealing heat treatment furnace:

1、Brief introduction of Segmented annealing heat treatment furnace

Segmented annealing heat treatment furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,It is mostly used in Metal forging heating, Metal heat treatment, Energy conservation and environmental protection, Metal tempering, Metal melting and casting, Improve production efficiency and so on,is designed by One-combustion energy saving with advanced technology。

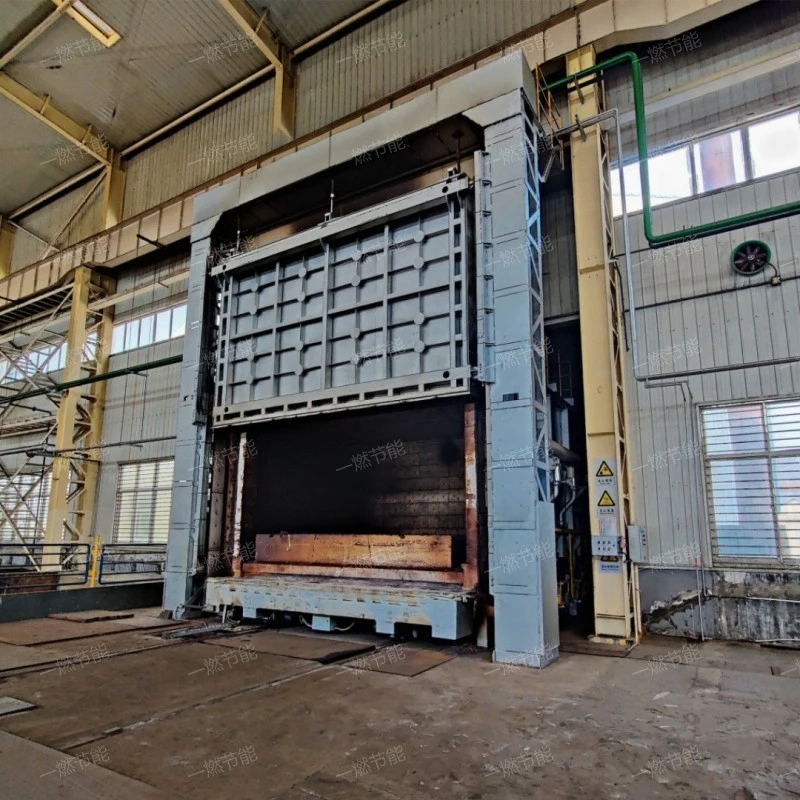

Segmented annealing heat treatment furnace

2、Working principle of Segmented annealing heat treatment furnace

Segmented annealing heat treatment furnaceat work,The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,Cheap and high quality。

Segmented annealing heat treatment furnace

3、Segmented annealing heat treatment furnace explanation video

On-site aerial photography of Segmented annealing heat treatment furnace。

Segmented annealing heat treatment furnace

As you can see from the live video.,One-combustion energy saving widely used inlight industry,surface treatment,material,war industry,automobile and other industries。

4、Introduction of Segmented annealing heat treatment furnace characteristics

Segmented annealing heat treatment furnace has the following characteristics

- Easy to maintain

- energy saving and environmental protection

- Easy to control

- Efficient heating

- Stable and reliable

The structural design of the Segmented annealing heat treatment furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

Natural gas is a kind of clean energy, which produces less waste gas and waste smoke after combustion and has little environmental pollution. At the same time, through wall regenerative combustion technology, flue gas waste heat recovery system and other technical means, the Segmented annealing heat treatment furnace further improves energy utilization efficiency and reduces energy consumption and emissions.

By adjusting the burner and ventilation system, the temperature and atmosphere in the furnace can be accurately controlled to meet the heating requirements of different metal materials.

The Segmented annealing heat treatment furnace can heat the metal to the required forging temperature in a very short time, reducing the loss caused by the oxidation of the metal.

The Segmented annealing heat treatment furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

Segmented annealing heat treatment furnace

5、Segmented annealing heat treatment furnace price consultation

The Segmented annealing heat treatment furnace price is introduced as follows:

- product function

- After-sales service level

- market competition

- Model specification

- product configuration

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Segmented annealing heat treatment furnace manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Segmented annealing heat treatment furnace price can meet the purchasing needs of customers.

Market supply and demand is the inevitable law of market development, with more market supply, less demand and lower product prices; The market supply is small, and people's demand is large. "Things are scarce and expensive", the product price will increase accordingly, and the price of One-combustion energy saving Segmented annealing heat treatment furnace will also conform to this market law.

The same product, even with different specifications and models and different configurations, has different costs, so the price will be different.

Usually, the quotation of Segmented annealing heat treatment furnace changes with its configuration, but the quotation is different according to the different needs of customers and different product configurations.

Segmented annealing heat treatment furnace

6、One-combustion energy saving company service

Customers should not only consider quality, performance and price factors when purchasing Segmented annealing heat treatment furnace, but also consider the after-sales service of manufacturers. Good after-sales service can reduce many unnecessary troubles for customers. One-combustion energy saving Factory always adheres to the service attitude of "customer is God", implements high-standard and high-quality after-sales service attitude, conducts regular customer satisfaction surveys, and strictly supervises the quality of after-sales service, so as to relieve customers' purchasing concerns and make purchasing customers completely worry-free.。

One-combustion energy saving

Segmented annealing heat treatment furnaceThe metal material can be heated to the required temperature in a short time, and the production efficiency is improved.、Using regenerative combustion system or advanced burner design can realize the uniform distribution of temperature in the furnace, ensure the uniform heating of metal materials and improve product quality.、Efficient combustion and waste heat recovery system can significantly reduce energy consumption, thus reducing operating costs.、It can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.、Usually equipped with intelligent control system, it can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.,It is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,at the start of the operation,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.。

Related recommendation

-

What is a Metallurgical heating furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

室式电阻炉

2023-03-13 -

井式天然气台车炉

2023-09-11 -

What is a Large scale tubular roaster? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

台车高温退火炉

2023-05-19 -

What is a Solid state heat treatment furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

Introduction to Isothermal spheroidization annealing industrial furnace, how much is the price of the heating furnace?

2025-5-27 -

What is a Automatic opening and closing resistance furnace? Introduction to the advantages and characteristics of Trolley resistance heating furnace functions

2025-5-27 -

Introduction to Titanium alloy heat treatment trolley furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

Introduction to Roller bottom guide rail annealing furnace and Forging furnace advantages and features

2025-5-27