Introduction to Aluminum alloy heat treatment electric furnace, Trolley electric heating furnace advantages, characteristics and principles

Aluminum alloy heat treatment electric furnaceis a kind of high-temperature heating equipment with high efficiency, environmental protection and easy control.。

1、Brief introduction of Aluminum alloy heat treatment electric furnace

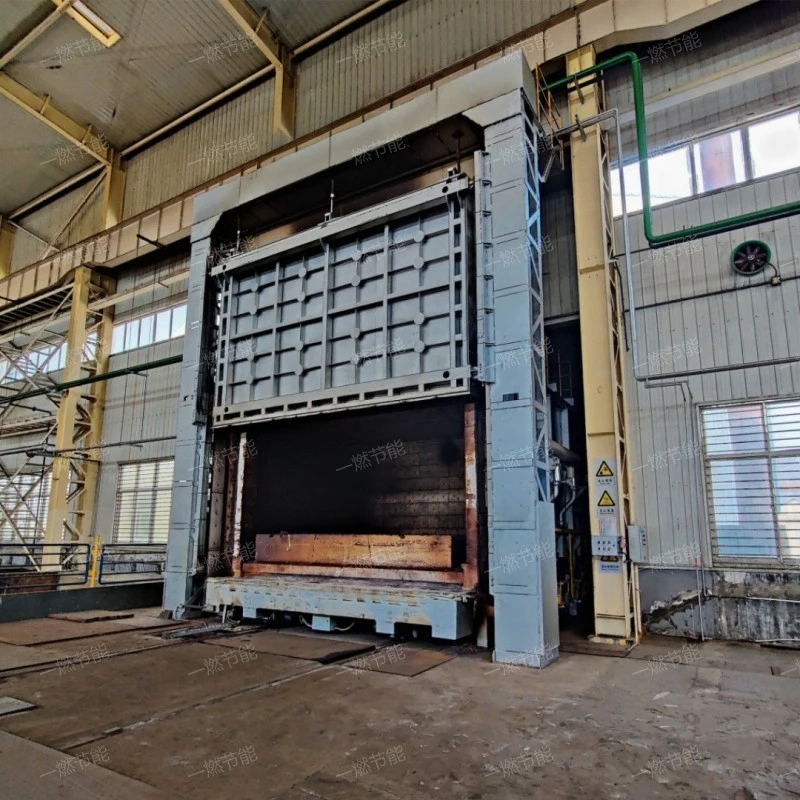

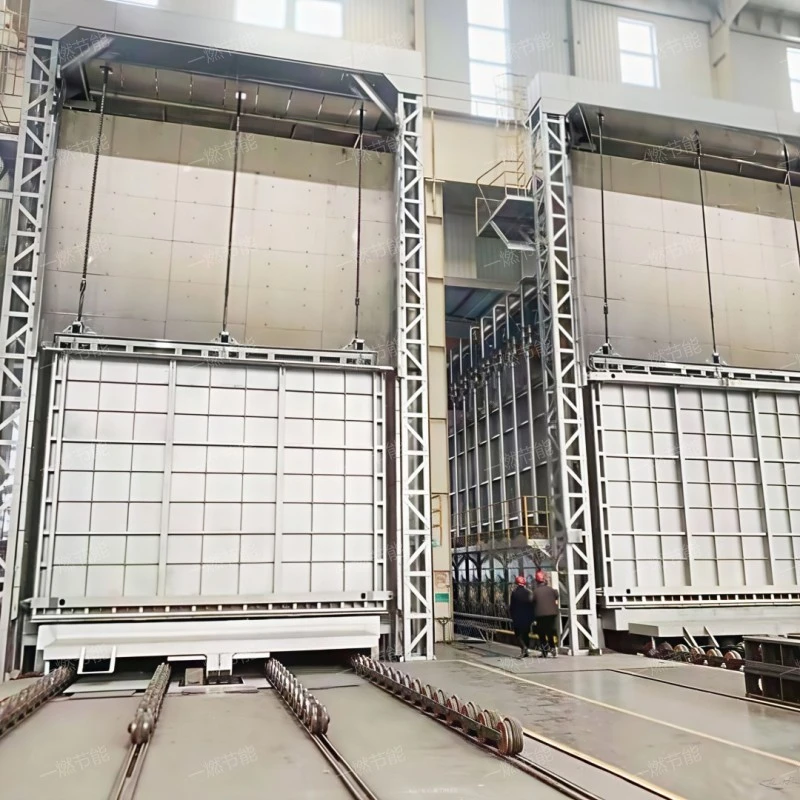

Aluminum alloy heat treatment electric furnaceis an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.,it can be used in machinery, glass, chemical industry, fireproofing, New material development and other industries,it has the functions of anneal, hardening and tempering, Casting heating, heat treatment and temper,the product looks beautiful.,it is mainly composed of heating element, fire door, furnace shell, Temperature control system and furnace chamber,This Aluminum alloy heat treatment electric furnaceSimple structure and advanced technology.。

Aluminum alloy heat treatment electric furnace

2、Aluminum alloy heat treatment electric furnace use

The purpose of Aluminum alloy heat treatment electric furnace is introduced as follows:

- New material development

- powder metallurgy

- Ceramic and glass industries

- Metal heat treatment

- Metal melting and casting

Used for synthesis and heat treatment of special materials and new materials.

Used for sintering and heat treatment of powder.

Used for baking and annealing of ceramics and glass.

Such as quenching, normalizing, annealing, tempering, etc.

Used for melting low melting point metals and alloys.

Aluminum alloy heat treatment electric furnace

3、Aluminum alloy heat treatment electric furnace structure composition

The Aluminum alloy heat treatment electric furnace structure is introduced as follows:

- thermal insulation (material)

- control system

- furnace body

- fire door

- base

Thermal insulation materials are used to reduce heat loss and keep the temperature in the furnace stable. Commonly used thermal insulation materials include ceramic fibers, refractory fibers, etc. These materials have the characteristics of [commodity characteristics].

The control system is the command center of the Aluminum alloy heat treatment electric furnace, which is usually composed of temperature controller, power regulator and thermocouple. These components work together to realize real-time monitoring and automatic adjustment of the temperature in the furnace.

The furnace body is usually made of high-temperature and corrosion-resistant materials, such as high-quality steel plates, refractory bricks and ceramic fibers. These materials can withstand thermal stress and mechanical stress at high temperature, ensuring the stability and durability of the furnace body.

The furnace Aluminum alloy heat treatment electric furnace is the passage for operators to enter and leave the furnace, and it also plays a certain sealing role. It can effectively prevent the heat in the furnace from leaking out and the cold air from outside from entering, and ensure the stability of the temperature in the furnace.

Used to support the whole Aluminum alloy heat treatment electric furnace and ensure its stability.

Aluminum alloy heat treatment electric furnace

4、Aluminum alloy heat treatment electric furnace principle

Aluminum alloy heat treatment electric furnaceat runtime,It is the thermal effect of current, that is, when current passes through a conductor with a certain resistance, electric energy will be converted into heat energy, which will make the resistor heat up and transfer heat to the materials in the furnace.,is a common Aluminum alloy heat treatment electric furnace,usually used in metallurgy, Special material, machinery, pottery and porcelain, New material development and other fields。

Aluminum alloy heat treatment electric furnace

5、Aluminum alloy heat treatment electric furnace introduction video

Speak directly with facts on the spot。

Aluminum alloy heat treatment electric furnace

As you can see from the live video.,One-combustion energy saving it is mainly composed of furnace chamber, fire door, furnace shell, heating element and Temperature control system,productThe structural design is more advanced and reasonable.。

6、Aluminum alloy heat treatment electric furnace quotation

The Aluminum alloy heat treatment electric furnace price is introduced as follows:

- Sales model

- Company size

- specifications and models

- raw material

- Different regions

Each manufacturer's sales model is different, and the preferential degree of products is also different. Some manufacturers adopt the mode of "thin profit and quick turnover", and the price is relatively cheap. Some manufacturers sell their products at high prices to earn high profits. When purchasing products, they must compare the prices to avoid being cheated.

At present, there are many manufacturers of products on the market, some of which belong to direct selling manufacturers and some belong to middlemen. Direct selling manufacturers will cost less than middlemen, so the quotation for products will be lower. Therefore, it is recommended that customers buy products from direct selling manufacturers of Aluminum alloy heat treatment electric furnace. In addition, even direct selling manufacturers have different capital status, strength level and technology, and the quotation for Aluminum alloy heat treatment electric furnace will be different.

There are many specifications and models of Aluminum alloy heat treatment electric furnace in the market now. Under normal circumstances, the price of large-sized Aluminum alloy heat treatment electric furnace is definitely higher than that of small-sized Aluminum alloy heat treatment electric furnace.

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

One-combustion energy saving has a geographical advantage, where the transportation is developed, the product transportation cost is low, and the price and consumption level are also low, which provides a good sales environment for Aluminum alloy heat treatment electric furnace.

Aluminum alloy heat treatment electric furnace

Aluminum alloy heat treatment electric furnaceThe temperature control precision is high, and the Aluminum alloy heat treatment electric furnace is equipped with advanced temperature control system, which can accurately control the temperature in the furnace and ensure the stability and reliability of the process.、The temperature uniformity is good, and the temperature distribution in the Aluminum alloy heat treatment electric furnace is relatively uniform, which is helpful to reduce the temperature gradient in the heating process of the workpiece and improve the heating quality.、Fast heating, the Aluminum alloy heat treatment electric furnace can quickly raise the temperature to the set temperature, shorten the heating time and improve the production efficiency. In particular, the heating Aluminum alloy heat treatment electric furnace is directly heated, and the current directly passes through the material, so the heating speed is faster.、The safety is high, and the Aluminum alloy heat treatment electric furnace is electrically controlled, which has higher safety than the fuel stove and can effectively avoid potential safety hazards such as fire and explosion.、Wide application range, the Aluminum alloy heat treatment electric furnace is suitable for heating workpieces of various shapes and sizes, and can meet the heating requirements of different industries and processes.,It can be used for quench, Metal heat treatment heating, Heating before metal forging, Melting of low melting point metal, anneal, anneal and so on。

Related recommendation

-

What is a Step furnace denitrification? Introduction to the advantages and characteristics of the SCR denitration system

2025-5-27 -

What is a Thermal insulation annealing furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

What is a Local annealing furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

What is a Rail car forging heating furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

Introduction to Resistance heating metal annealing furnace, how much is the price of the Trolley electric heating furnace?

2025-5-27 -

What is a Stick style isothermal quenching furnace? Introduction to the advantages and characteristics of the Forging furnace

2025-5-27 -

Introduction to Chain type quenching heat treatment furnace, forging furnace specifications, model parameters

2025-5-27 -

Introduction to Automatic temperature control electric heating furnace, Trolley electric furnace specifications, model parameters

2025-5-27 -

Introduction to Gas trolley furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

辊底式炉

2023-03-30