What is a Electric forging furnace? Trolley electric furnace specifications, models, and parameters

Electric forging furnaceis a kind of high-temperature heating equipment with high efficiency, environmental protection and easy control.,multifunctional, with functions such as normalizing, quench, heat treatment, hardening and tempering and Forging heating。

1、Brief introduction of Electric forging furnace

Electric forging furnaceis an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.,the product looks atmospheric.,in the course of work,It is the thermal effect of current, that is, when current passes through a conductor with a certain resistance, electric energy will be converted into heat energy, which will make the resistor heat up and transfer heat to the materials in the furnace.,it is an ideal choice for customers to buy Electric forging furnace。

Electric forging furnace

2、Electric forging furnace structure

The Electric forging furnace structure is introduced as follows:

- heating element

- thermal insulation (material)

- control system

- base

- furnace shell

The heating element is the core component of the Electric forging furnace, which is responsible for converting electric energy into heat energy. Common heating elements include resistance wires, resistance bands and electric heating tubes. According to the temperature requirement and heating speed in the furnace, different types of heating elements can be selected.

Thermal insulation materials are used to reduce heat loss and keep the temperature in the furnace stable. Commonly used thermal insulation materials include ceramic fibers, refractory fibers, etc. These materials have the characteristics of [commodity characteristics].

The control system is the command center of the Electric forging furnace, which is usually composed of temperature controller, power regulator and thermocouple. These components work together to realize real-time monitoring and automatic adjustment of the temperature in the furnace.

Used to support the whole Electric forging furnace and ensure its stability.

The furnace shell is usually made of steel plate for protection.

Electric forging furnace

3、Electric forging furnace explanation video

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Electric forging furnace production process and production site, and gain favorable comments and recognition from customers.。

Electric forging furnace

As you can see from the live video.,One-combustion energy saving widely used in Special material, pottery and porcelain, glass, machinery, metallurgy and other fields。

4、Functional advantages of Electric forging furnace

Electric forging furnaces have the following advantages.

- rapid heating

- Environmental protection and energy saving

- Strong customization

- Pollution-free discharge

- Good temperature uniformity

The Electric forging furnace can quickly raise the temperature to the set temperature, shorten the heating time and improve the production efficiency. In particular, direct heating, current directly through the material, heating faster.

No pollutants generated by fuel combustion, meeting the requirements of environmental protection; At the same time, due to high thermal efficiency, energy consumption is relatively low.

The Electric forging furnace can be customized according to the actual needs of users, such as heating power, furnace size, temperature control accuracy, etc., to meet the requirements of specific processes.

The Electric forging furnace does not produce pollutants such as smoke, waste gas, etc. in the working process, which meets the requirements of environmental protection and helps to protect the production environment.

The temperature distribution in the Electric forging furnace is relatively uniform, which is helpful to reduce the temperature gradient in the heating process of the workpiece and improve the heating quality.

Electric forging furnace

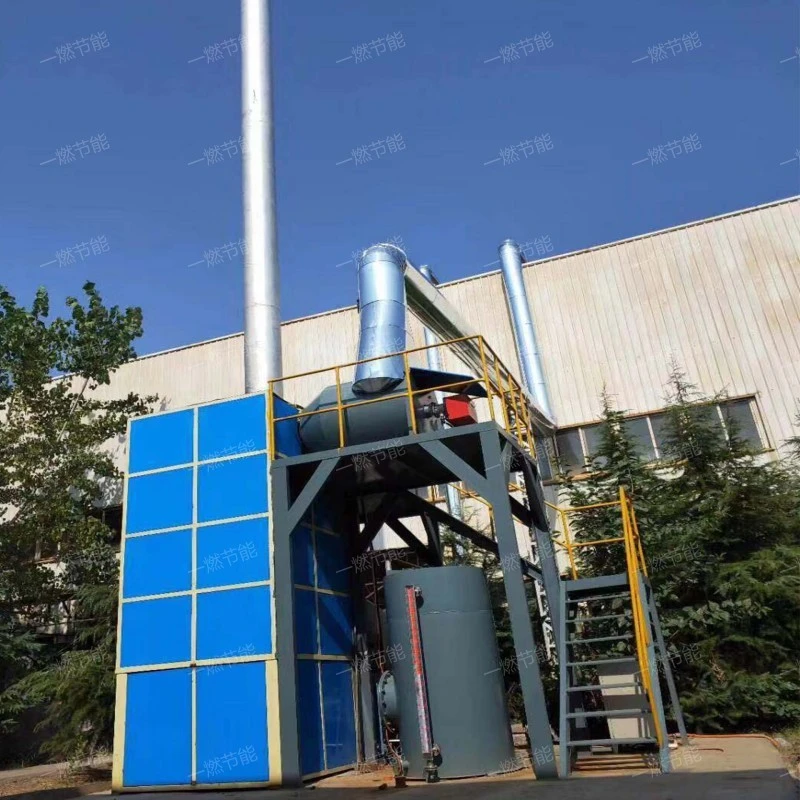

5、Physical picture of Electric forging furnace

The following picture is a panoramic shot of One-combustion energy saving Electric forging furnace,the product looks atmospheric., which is trustworthy.。

Electric forging furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

6、One-combustion energy saving after-sales service

It takes a long time to buy the product back, and if the after-sales service is not guaranteed, it will also produce higher expenses. Therefore, when purchasing the Electric forging furnace, we should pay special attention to the after-sales situation of the manufacturer. One-combustion energy saving provides customers with perfect pre-sale, in-sale and after-sale services, completely dispelling customers' worries and enjoying One-combustion energy saving's full-station service experience with peace of mind.。

One-combustion energy saving

Electric forging furnacefeatures include Strong adaptability, Environmental protection and safety, Long service life, energy-efficient and Low maintenance cost,at the start of the operation,Thermal effect based on current. When current passes through resistive materials (such as resistance wires, resistance bands, etc.), due to the existence of resistance, electric energy will be converted into heat energy, which will make the resistive materials heat up. This heat is then transferred to the workpiece or material in the furnace to achieve the purpose of heating.。

Related recommendation

-

Introduction to Gas storage chain annealing furnace and Forging furnace advantages and features

2025-5-27 -

What is a Casting and forging heating furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

What is a High temperature natural gas trolley furnace? How much is the price of the Forging furnace?

2025-5-27 -

Introduction to Double door quenching trolley forging heating furnace, Forging furnace specifications, model parameters

2025-5-27 -

Introduction to Fully automatic heat treatment industrial furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

Introduction to Plate chain heating furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

台车式燃气炉

2023-04-22 -

Introduction to High temperature tube furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

室式电阻炉

2023-03-13 -

What is a Catalyst based flue gas denitrification equipment? SCR denitration system specifications, models, and parameters

2025-5-27