Introduction to Angle iron heating furnace, how much is the price of the heating furnace?

Angle iron heating furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,It has a wide range of uses, and is often used inMetal tempering,Energy conservation and environmental protection,Metal melting and casting,Improve production efficiency,Metal forging heating and so on,at the start of the operation,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、Efficient combustion and waste heat recovery system can significantly reduce energy consumption, thus reducing operating costs.、Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials.、Suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.,it is usually composed of furnace chamber, recovery of waste heat, furnace chamber, Radiation chamber and convection chamber,This productThe overall structural design is simple, diverse and beautiful.。The following is to introduce the Angle iron heating furnace:

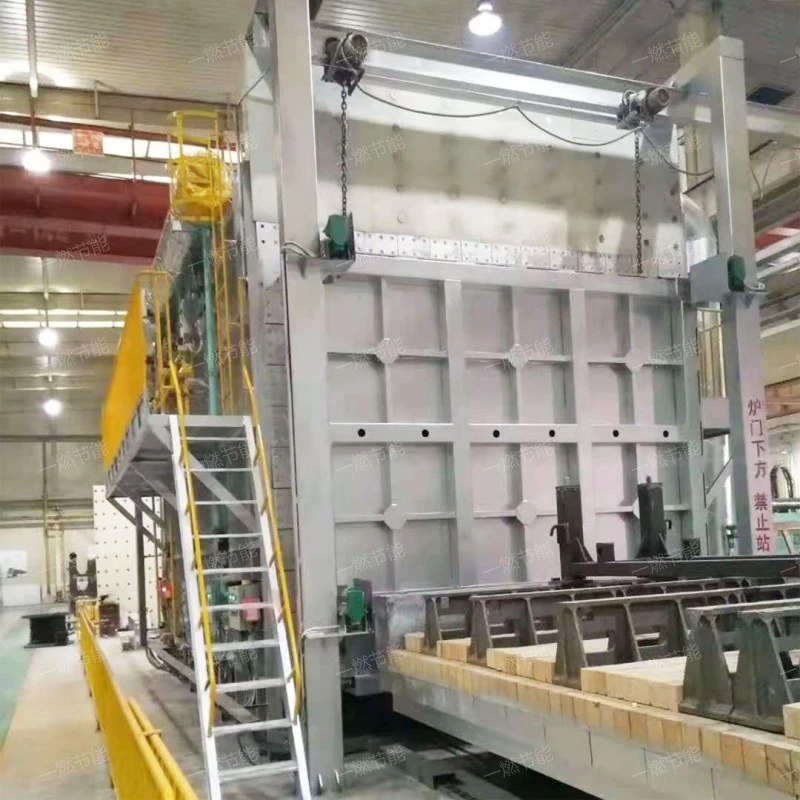

1、Brief introduction of Angle iron heating furnace

Angle iron heating furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,the product looks beautiful.,features include Easy to control, energy-efficient, Strong adaptability, Easy to control and energy-efficient。

Angle iron heating furnace

2、Working principle of Angle iron heating furnace

Angle iron heating furnacein the course of work,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,favorable price。

Angle iron heating furnace

3、Structural advantages of Angle iron heating furnace

The Angle iron heating furnace has the following structure

- Radiation chamber

- Waste heat recovery system

- ventilation system

- convection chamber

- combustor

The heat load of the main place for Angle iron heating furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Angle iron heating furnace

4、Functional advantages of Angle iron heating furnace

Angle iron heating furnaces have the following advantages.

- Improve product quality

- Uniform heating

- Multiple fuel options

- Extend the service life of equipment

- Wide application range

Because the Angle iron heating furnace can realize uniform heating and precise control, it is helpful to improve the product quality and yield of metal materials.

The Angle iron heating furnace adopts regenerative combustion system or advanced burner design, which can realize uniform distribution of temperature in the furnace, ensure uniform heating of metal materials and improve product quality.

Although the Angle iron heating furnace mainly uses natural gas as fuel, some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.

The Angle iron heating furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The Angle iron heating furnace is suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.

Angle iron heating furnace

5、How much is the Angle iron heating furnace?

The Angle iron heating furnace price is introduced as follows:

- brand

- technology

- market factors

- Model specification

- deploy

Different brands of products in the same series have more or less differences in product prices, and different brands of Angle iron heating furnace have more or less differences in price.

The more advanced the technology, the higher the price will be, otherwise the equipment price will be low, and users must pay attention to whether their own technology meets the production requirements when purchasing equipment.

The difference between the supply and demand of manufacturers and customers will also affect the Angle iron heating furnace price. When the demand of customers on the market increases and the supply of products by manufacturers is small, the Angle iron heating furnace price will increase with the increase of demand. On the contrary, when the supply of product manufacturers on the market exceeds the demand of customers, the Angle iron heating furnace price will decrease.

The same type of equipment, with different models and sizes, has different investment costs, so the quotations to customers are naturally different. Generally speaking, the larger the model, the higher the price, and the smaller the model, the lower the price.

The higher the hardware configuration, the greater the product cost, so the sales price of such products will be higher. One-combustion energy saving pays special attention to the hardware configuration of products, so One-combustion energy saving Angle iron heating furnace has a higher cost performance.

Angle iron heating furnace

6、One-combustion energy saving's after-sales service

One-combustion energy saving adheres to the service concept of "being honest, doing things according to rules, pioneering and innovating, mutual benefit and win-win", and serves every customer wholeheartedly to create quality products and intimate services for customers.。

One-combustion energy saving

Angle iron heating furnacefeatures include Easy to maintain, Stable and reliable, energy saving and environmental protection, Strong adaptability and Easy to control,at work,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,The structure is novel, special, advanced, reasonable and scientific.,generally, it is composed of combustor, ventilation system, ventilation system, recovery of waste heat, ventilation system and other major components。

Related recommendation

-

Introduction to Double trolley tempering furnace and Forging furnace working principle

2025-5-27 -

What is a Round tube rotary roasting furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

What is a Trolley forging furnace in heat treatment workshop? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Stepping bottom quenching and tempering furnace and forging furnace working principle

2025-5-27 -

Introduction to Large trolley electric furnace, Trolley electric furnace specifications, model parameters

2025-5-27 -

Introduction to Multi functional trolley forging heating furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

Introduction to Three stage walking industrial furnace, how much is the price of the heating furnace?

2025-5-27 -

Introduction to Resistance continuous tempering furnace, Trolley electric heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Annealing gas trolley furnace, how much is the price of the forging furnace?

2025-5-27 -

What is a Continuous positive furnace? heating furnace specifications, models, and parameters

2025-5-27