Introduction to Split type annealing heating furnace, forging furnace specifications, model parameters

Split type annealing heating furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,features include energy saving and environmental protection, energy-efficient, Easy to control, Stable and reliable and Easy to maintain,It has the functions of Metal forging heating, Metal heat treatment, Improve production efficiency, Metal forging heating and Metal tempering。The following is to introduce the Split type annealing heating furnace:

1、Brief introduction of Split type annealing heating furnace

Split type annealing heating furnaceIt is a forging heating device using gas as fuel.,it is widely used in building materials, war industry, surface treatment, petroleum and automobile,Simple structure and reliable operation.,it is mainly composed of furnace chamber, convection chamber, furnace chamber, recovery of waste heat and combustor,has been favored by more and more customers.。

Split type annealing heating furnace

2、Advantages of Split type annealing heating furnace principle

Split type annealing heating furnaceat work,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.。

Split type annealing heating furnace

3、Introduction of Split type annealing heating furnace characteristics

Split type annealing heating furnace has the following characteristics

- Easy to maintain

- Easy to control

- Stable and reliable

- Easy to maintain

- Strong adaptability

The structural design of the Split type annealing heating furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The combustion system and ventilation system of the Split type annealing heating furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

The Split type annealing heating furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The structural design of the Split type annealing heating furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The Split type annealing heating furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

Split type annealing heating furnace

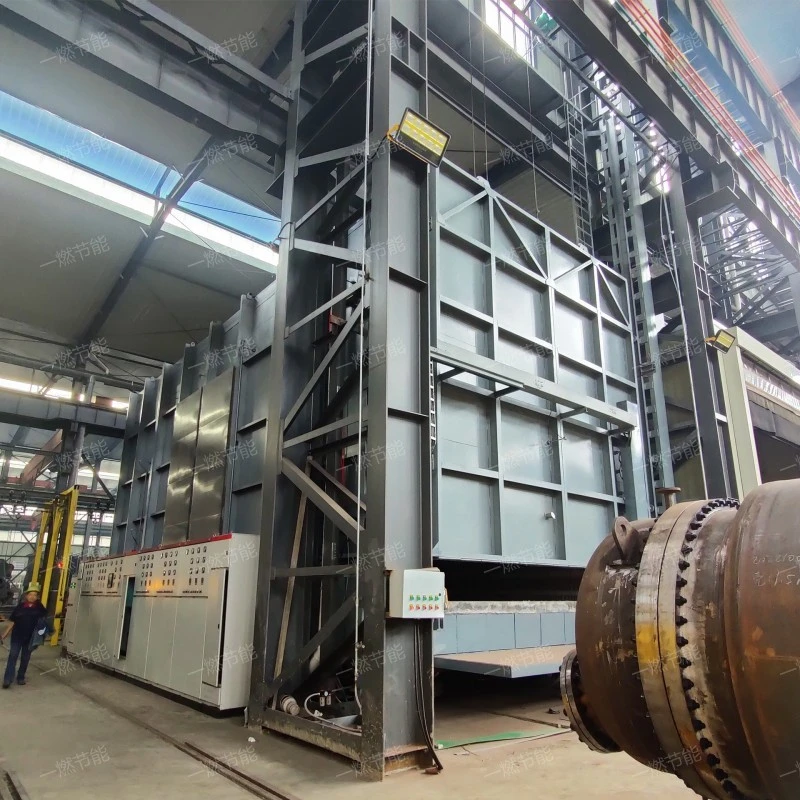

4、Split type annealing heating furnace field real shot

Exquisite design, excellent material selection, reliable quality and high-definition pictures for our customers to visit.。

Split type annealing heating furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Split type annealing heating furnace function

Split type annealing heating furnacemultifunctional, with functions such as Casting heating, Forging heating, temper, normalizing and quench,it can be used in electron, building materials, machinery, shipping, surface treatment and other industries,It is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,It can be used for Metal heat treatment, Improve production efficiency, Energy conservation and environmental protection, Metal melting and casting, Improve production efficiency, Energy conservation and environmental protection and so on,Easy to maintain,energy saving and environmental protection,Strong adaptability,Stable and reliable,Easy to control。

Split type annealing heating furnace

6、Split type annealing heating furnace quotation

The Split type annealing heating furnace price is introduced as follows:

- Reasonable cost

- product function

- quality

- select a qualified person

- type of operation

One-combustion energy saving has a large production scale, strong manufacturing strength and high degree of automation in product production. In such a manufacturing environment, the cost of manufacturing Split type annealing heating furnace in One-combustion energy saving is greatly reduced.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The price of Split type annealing heating furnace is affected by the quality of products. Only when the products are of good quality can we create greater profits for customers and recover the costs for customers as soon as possible. However, products with good quality have a lot of investment in technology, manpower and time, so their prices are higher than those of ordinary products. On the contrary, the products of general quality are equal in effort and gain, and the sales price is also low. But there are exceptions. Many manufacturers often adopt the mode of small profits but quick turnover. If customers can choose products with high cost performance, it is a good choice for long-term investment.

Different manufacturers have different material selection standards. The better the quality of the selected materials, the more expensive the products will be. On the contrary, the prices will be low. However, to avoid customers being deceived, compare several products of the same specification and model before deciding to purchase.

There are direct selling manufacturers and agents in the market. Agents are higher than direct selling manufacturers, mainly because agents get goods from manufacturers, sell them to customers and earn the difference from middlemen, so the natural price is higher.

Split type annealing heating furnace

Split type annealing heating furnaceit has the structure of ventilation system, Radiation chamber, ventilation system, convection chamber and recovery of waste heat,the main features are Easy to control, energy saving and environmental protection, energy-efficient, Strong adaptability and Stable and reliable,it is widely used inshipping,pharmacy,aerospace,light industry,Machinery manufacturing and other industries。

Related recommendation

-

天然气贯通炉

2023-03-09 -

Introduction to Car industrial annealing furnace and forging furnace advantages and features

2025-5-27 -

Introduction to Trolley industrial electric heating furnace, Trolley electric heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Double trolley aluminum alloy furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

What is a Rapid Annealing Heating Furnace? forging furnace specifications, models, and parameters

2025-5-27 -

What is a Carbon fiber trolley forging furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

台车式光亮退火炉

2023-07-08 -

Introduction to Adjustable temperature resistance furnace, introduction to Trolley resistance furnace advantages and characteristics

2025-5-27 -

What is a Stick type continuous heat treatment furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

Introduction to Round tube annealing furnace, advantages, characteristics and principles of forging furnace

2025-5-27