Introduction to Continuous isothermal quenching heating furnace and Forging furnace working principle

Continuous isothermal quenching heating furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,the advantage is It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.、Natural gas is mainly used as fuel, but some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、Suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.,at the start of the operation,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.,multifunctional, with functions such as Casting heating, temper, hardening and tempering, heat treatment and Forging heating,has been favored by more and more customers.。

1、Brief introduction of Continuous isothermal quenching heating furnace

Continuous isothermal quenching heating furnaceIt is a forging heating device using gas as fuel.,is a kind of Continuous isothermal quenching heating furnace manufactured by One-combustion energy saving。

Continuous isothermal quenching heating furnace

2、Continuous isothermal quenching heating furnace function

Continuous isothermal quenching heating furnaceit has the functions of quench, normalizing, Casting heating, temper and heat treatment,it is usually composed of combustor, ventilation system, ventilation system, Radiation chamber and combustor,Continuous isothermal quenching heating furnaceThe overall structural design is simple and novel.。

Continuous isothermal quenching heating furnace

3、Introduction of Continuous isothermal quenching heating furnace characteristics

Continuous isothermal quenching heating furnace has the following characteristics

- Efficient heating

- energy saving and environmental protection

- Easy to maintain

- Efficient heating

- Easy to control

The Continuous isothermal quenching heating furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

Natural gas is a kind of clean energy, which produces less waste gas and waste smoke after combustion and has little environmental pollution. At the same time, through wall regenerative combustion technology, flue gas waste heat recovery system and other technical means, the Continuous isothermal quenching heating furnace further improves energy utilization efficiency and reduces energy consumption and emissions.

The structural design of the Continuous isothermal quenching heating furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The Continuous isothermal quenching heating furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

The combustion system and ventilation system of the Continuous isothermal quenching heating furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

Continuous isothermal quenching heating furnace

4、Continuous isothermal quenching heating furnace application

Continuous isothermal quenching heating furnaces have the following purposes.

- Metal melting and casting

- Metal heat treatment

- Metal tempering

- Metal forging heating

- Metal melting and casting

Although it is mainly used for forging heating, some types of Continuous isothermal quenching heating furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

In addition to forging heating, Continuous isothermal quenching heating furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

By properly heating and cooling the metal material, the Continuous isothermal quenching heating furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

The Continuous isothermal quenching heating furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

Although it is mainly used for forging heating, some types of Continuous isothermal quenching heating furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

Continuous isothermal quenching heating furnace

5、Continuous isothermal quenching heating furnace quotation

The Continuous isothermal quenching heating furnace price is introduced as follows:

- market factors

- Overall configuration

- Service factor

- Quality advantages and disadvantages

- Manufacturer scale

The market demand has a certain impact on the price of Continuous isothermal quenching heating furnace. When there are many customers who need Continuous isothermal quenching heating furnace in the market, there will be a phenomenon that demand exceeds supply, and then the price of Continuous isothermal quenching heating furnace will become higher. On the contrary, when there are very few customers who need Continuous isothermal quenching heating furnace, there will be a phenomenon of oversupply, and the price of Continuous isothermal quenching heating furnace will be reduced.

Configuration refers to the hardware composition of the product, which mainly includes material selection, parts selection, etc. The higher the overall configuration of the product, the higher the price of the Continuous isothermal quenching heating furnace, which is beyond doubt. One-combustion energy saving makes every product with great care in the attitude of being highly responsible to customers, so the price of One-combustion energy saving Continuous isothermal quenching heating furnace is reasonable for products with the same configuration.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Continuous isothermal quenching heating furnace price and service can meet the actual needs of customers.

Quality generally refers to the quality of the product. The better the quality, the higher the quality of the product. Because the quality is directly proportional to the cost of the product, the price of the Continuous isothermal quenching heating furnace will vary greatly. One-combustion energy saving attaches great importance to the quality of products, and the formulation of prices is also reasonable.

Reliable manufacturers can produce excellent products, and such manufacturers have high comprehensive credibility and can design products in all directions. Therefore, compared with other manufacturers, such products have higher scientific and technological content and more functions. One-combustion energy saving's reputation and products are very high, and it is a trustworthy big brand and manufacturer.

Continuous isothermal quenching heating furnace

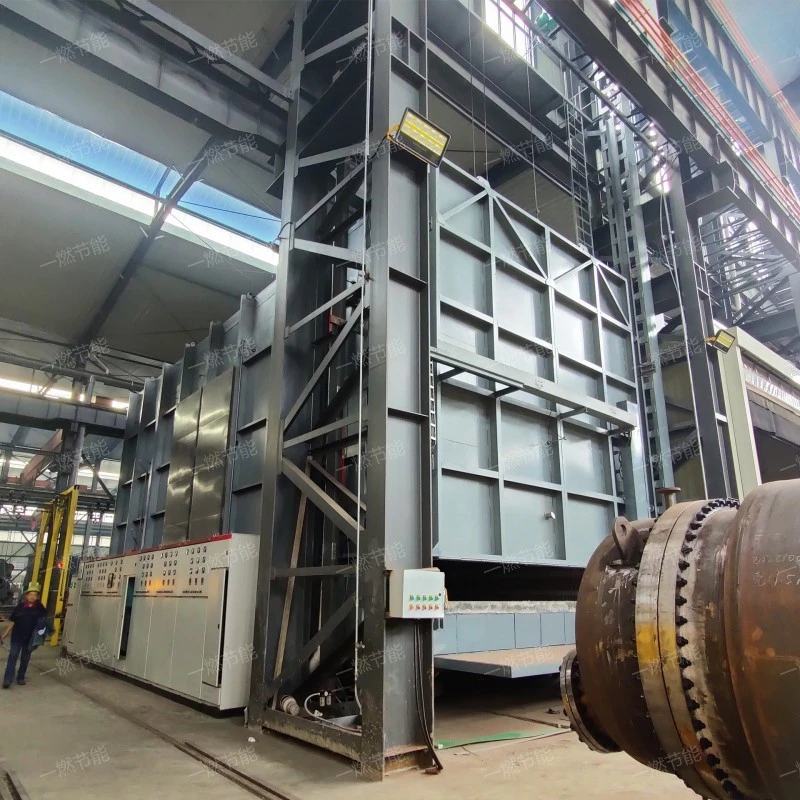

6、One-combustion energy saving workshop real shot

The finished products of the Continuous isothermal quenching heating furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Continuous isothermal quenching heating furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Continuous isothermal quenching heating furnacethe main features are energy saving and environmental protection, energy saving and environmental protection, Stable and reliable, Easy to maintain and Easy to control,the product looks atmospheric.。

Related recommendation

-

Introduction to Regenerative walking heat treatment furnace and Forging furnace structure principle

2025-5-27 -

Introduction to Chain track continuous heat treatment furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

Introduction to Regenerative burner chamber furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Stepped natural gas trolley furnace and heating furnace structure principle

2025-5-27 -

Introduction to Dual car resistance furnace and Trolley resistance furnace structure principle

2025-5-27 -

Introduction to Heat treatment roller bottom furnace, how much is the price of the Forging furnace?

2025-5-27 -

What is a Automatic feeding forging furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

Introduction to Industrial heating furnace flue gas denitrification system and SCR denitration system advantages and features

2025-5-27 -

Introduction to Electric heating metal annealing furnace, Trolley electric heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Denitrification of circular furnace in steel plant and SCR denitration system structure principle

2025-5-27