Introduction to Continuous quenching and tempering heating furnace and heating furnace advantages and features

Continuous quenching and tempering heating furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,the product looks beautiful.。The following is to introduce the Continuous quenching and tempering heating furnace:

1、Brief introduction of Continuous quenching and tempering heating furnace

Continuous quenching and tempering heating furnaceIt is a forging heating device using gas as fuel.,it is widely used in petroleum, heat treatment, building materials, automobile and shipping,at work,The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,Commonly used inMetal melting and casting,Metal tempering,Metal heat treatment,Energy conservation and environmental protection,Energy conservation and environmental protection and so on,is a kind of Continuous quenching and tempering heating furnace manufactured by One-combustion energy saving。

Continuous quenching and tempering heating furnace

2、Functional advantages of Continuous quenching and tempering heating furnace

Continuous quenching and tempering heating furnaces have the following advantages.

- easy to operate

- Reduce operating costs

- Rapid temperature rise

- Extend the service life of equipment

- Efficient combustion

The operation interface of the Continuous quenching and tempering heating furnace is friendly and easy for operators to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.

The efficient combustion and waste heat recovery system of the Continuous quenching and tempering heating furnace can significantly reduce energy consumption, thus reducing operating costs.

The Continuous quenching and tempering heating furnace can heat the metal material to the required temperature in a short time, which improves the production efficiency.

The Continuous quenching and tempering heating furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The Continuous quenching and tempering heating furnace adopts advanced combustion technology and control system, which can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.

Continuous quenching and tempering heating furnace

3、Structural advantages of Continuous quenching and tempering heating furnace

The Continuous quenching and tempering heating furnace has the following structure

- Radiation chamber

- ventilation system

- Waste heat recovery system

- convection chamber

- combustor

The heat load of the main place for Continuous quenching and tempering heating furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Continuous quenching and tempering heating furnace

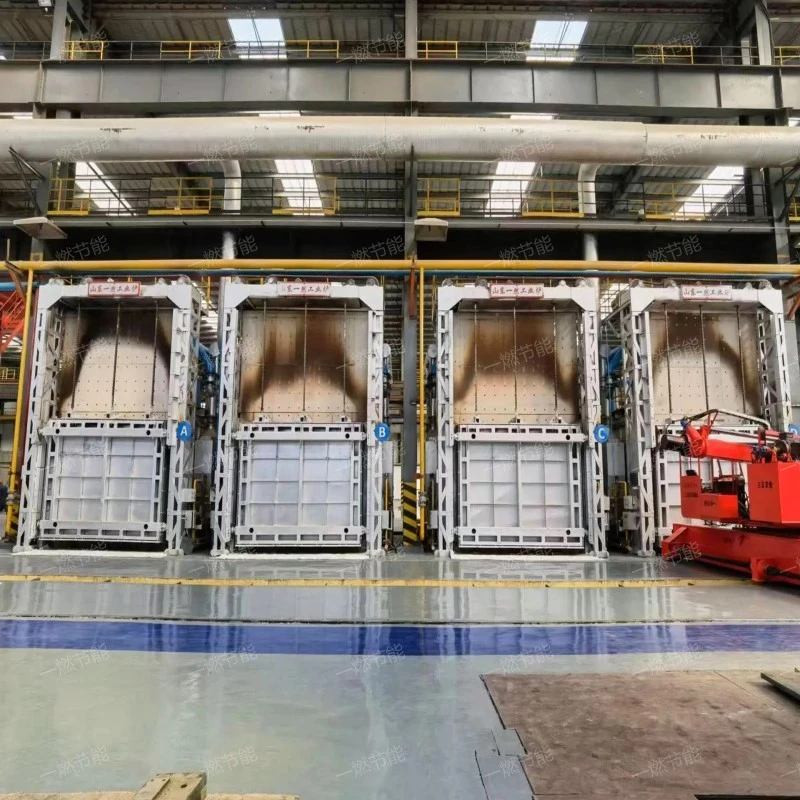

4、Continuous quenching and tempering heating furnace HD picture

Continuous quenching and tempering heating furnace picture at a glance, showing elegance.。

Continuous quenching and tempering heating furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、How much is the Continuous quenching and tempering heating furnace?

The Continuous quenching and tempering heating furnace price is introduced as follows:

- Cost input

- market demand

- select a qualified person

- technology content

- Parameter size

A Continuous quenching and tempering heating furnace needs to spend a lot of manufacturing costs from research and development to production to sales, including raw material costs, technical costs, labor costs, etc. The higher the manufacturing cost, the higher the price will be.

With the increasingly fierce competition of Continuous quenching and tempering heating furnace, market factors have a certain influence on the price of Continuous quenching and tempering heating furnace. When the demand in the market increases and the supply remains unchanged, the price will rise. On the contrary, the price will fall. When there is an increase in supply and the demand remains unchanged, the price will rise, on the contrary, the price will fall.

Different manufacturers have different material selection standards. The better the quality of the selected materials, the more expensive the products will be. On the contrary, the prices will be low. However, to avoid customers being deceived, compare several products of the same specification and model before deciding to purchase.

The more advanced the technology, the higher the price will be, otherwise the equipment price will be low, and users must pay attention to whether their own technology meets the production requirements when purchasing equipment.

Different models will have different specifications, which will lead to greater differences in the comprehensive configuration of products, which will also lead to greater changes in prices.

Continuous quenching and tempering heating furnace

6、One-combustion energy saving introduced

One-combustion energy saving is a strong and professional Continuous quenching and tempering heating furnace manufacturer, with advanced Continuous quenching and tempering heating furnace production technology and rich production experience. It will not only provide users with Continuous quenching and tempering heating furnace with Strong adaptability, but also provide users with complete pre-sales, in-sales and after-sales services for the benefit of users. Welcome new and old users to visit and buy.。

One-combustion energy saving

Continuous quenching and tempering heating furnaceis a popular Continuous quenching and tempering heating furnace,in the course of work,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,It is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.。

Related recommendation

-

Introduction to Multi tube bright annealing furnace, heating furnace specifications, model parameters

2025-5-27 -

What is a Pit type forging furnace? How much is the price of the Forging furnace?

2025-5-27 -

台车预热炉

2023-05-12 -

What is a Isothermal quenching heat treatment industrial furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

Introduction to Multi functional trolley heating furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

Introduction to Double pass industrial furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

What is a Axle heating furnace? Introduction to the Working Principle of forging furnace

2025-5-27 -

Introduction to Rotary quenching heating furnace, heating furnace specifications, model parameters

2025-5-27 -

What is a Energy saving industrial electric furnace? Trolley electric furnace specifications, models, and parameters

2025-5-27 -

What is a Forging heating furnace chamber type? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27