What is a Regenerative natural gas through forging furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

Regenerative natural gas through forging furnaceIt is a forging heating device using gas as fuel.,is based on One-combustion energy saving is a kind of Regenerative natural gas through forging furnace manufactured by One-combustion energy saving。The following is to introduce the Regenerative natural gas through forging furnace:

1、Brief introduction of Regenerative natural gas through forging furnace

Regenerative natural gas through forging furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,it is usually composed of Radiation chamber, ventilation system, ventilation system, convection chamber and recovery of waste heat,Regenerative natural gas through forging furnaceSimple structure and advanced technology.,it is widely used in chemical industry, surface treatment, building materials, Household necessities, Machinery manufacturing and other industries,is an advanced Regenerative natural gas through forging furnace developed by our company in combination with the actual situation of the industry。

Regenerative natural gas through forging furnace

2、Structural advantages of Regenerative natural gas through forging furnace

The Regenerative natural gas through forging furnace has the following structure

- Radiation chamber

- ventilation system

- Radiation chamber

- Waste heat recovery system

- ventilation system

The heat load of the main place for Regenerative natural gas through forging furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

The heat load of the main place for Regenerative natural gas through forging furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Regenerative natural gas through forging furnace

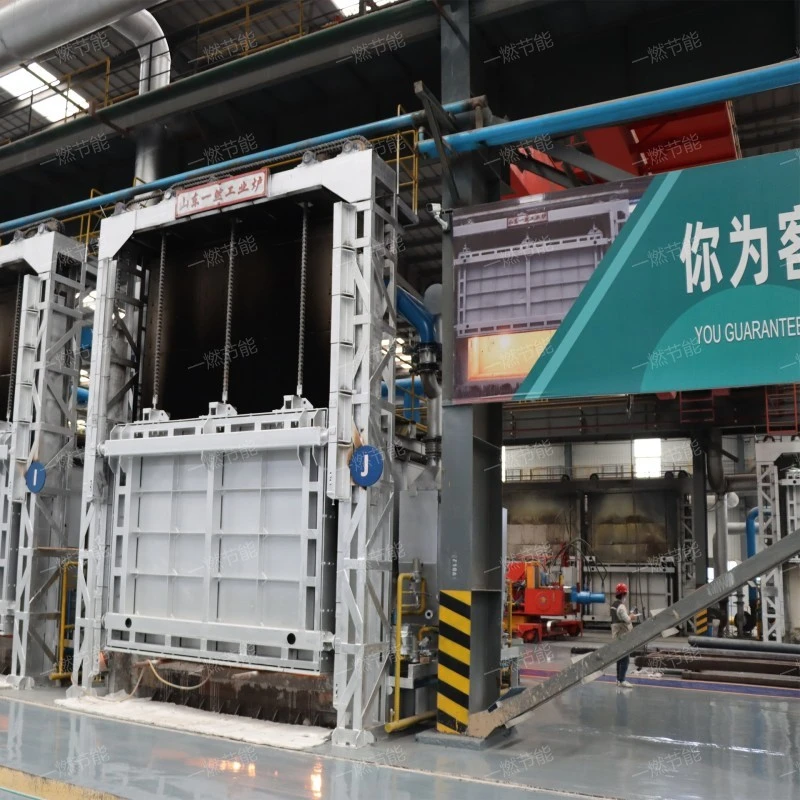

3、Regenerative natural gas through forging furnace work site real shot

Its appearance design is exquisite and elegant. The following is a high-definition picture of the factory for One-combustion energy saving's customers to choose and buy. You can contact online customer service at any time, make an appointment to visit the factory and take a shuttle bus from One-combustion energy saving.。

Regenerative natural gas through forging furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

4、Regenerative natural gas through forging furnace HD real shot

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Regenerative natural gas through forging furnace production process and production site, and gain favorable comments and recognition from customers.。

Regenerative natural gas through forging furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd features include energy saving and environmental protection, Easy to control, Stable and reliable, Easy to control and Easy to maintain。

5、Introduction of Regenerative natural gas through forging furnace characteristics

Regenerative natural gas through forging furnace has the following characteristics

- Stable and reliable

- Easy to maintain

- energy saving and environmental protection

- Easy to control

- Stable and reliable

The Regenerative natural gas through forging furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The structural design of the Regenerative natural gas through forging furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

As a clean energy source, gas produces less waste gas and waste smoke after combustion, which is beneficial to environmental protection. At the same time, some Regenerative natural gas through forging furnaces are also equipped with waste heat recovery system, which further improves the energy utilization efficiency.

The combustion system and ventilation system of the Regenerative natural gas through forging furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

The Regenerative natural gas through forging furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

Regenerative natural gas through forging furnace

Regenerative natural gas through forging furnaceis a common Regenerative natural gas through forging furnace,in the course of work,The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,The structural design is simple, novel and special.,Structure consists of Radiation chamber, furnace chamber, combustor, ventilation system, Radiation chamber and so on。

Related recommendation

-

Introduction to Side entry and side exit step heating furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

Introduction to Deep well heat treatment furnace and Forging furnace advantages and features

2025-5-27 -

What is a Regenerative natural gas heat treatment chain furnace? forging furnace specifications, models, and parameters

2025-5-27 -

What is a Continuous tempering industrial furnace? forging furnace specifications, models, and parameters

2025-5-27 -

What is a Natural gas tube furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Electric industrial furnace, introduction to Trolley resistance furnace advantages and characteristics

2025-5-27 -

Introduction to Full fiber medium temperature locomotive heating furnace, introduction to heating furnace function advantages and characteristics

2025-5-27 -

What is a Walking beam type billet heating furnace? How much is the price of the heating furnace?

2025-5-27 -

Introduction to High temperature tube quenching furnace, Forging furnace specifications, model parameters

2025-5-27 -

What is a Double door quenching trolley heating furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27