What is a Large scale stepper industrial furnace? Introduction to the principle of heating furnace structure

Large scale stepper industrial furnaceIt is a forging heating device using gas as fuel.,it can be used in aerospace, metallurgy, material, pharmacy, machinery and other industries,multifunctional, with functions such as temper, hardening and tempering, Forging heating, normalizing and quench,It can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.、Using regenerative combustion system or advanced burner design can realize the uniform distribution of temperature in the furnace, ensure the uniform heating of metal materials and improve product quality.、Suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.,the product looks beautiful.。

1、Brief introduction of Large scale stepper industrial furnace

Large scale stepper industrial furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.。

Large scale stepper industrial furnace

2、Structural advantages of Large scale stepper industrial furnace

The Large scale stepper industrial furnace structure is introduced as follows:

- Waste heat recovery system

- ventilation system

- furnace chamber

- combustor

- ventilation system

Used to recover the exhaust heat of the heating furnace. There are two kinds of recovery methods, one is to recover by preheating combustion air, so that the recovered heat can return to the furnace again; The other is to use another recovery system to recover heat. The former is called air preheating mode, and the latter is usually called waste heat boiler mode.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

A space for holding metallic materials for heating.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Large scale stepper industrial furnace

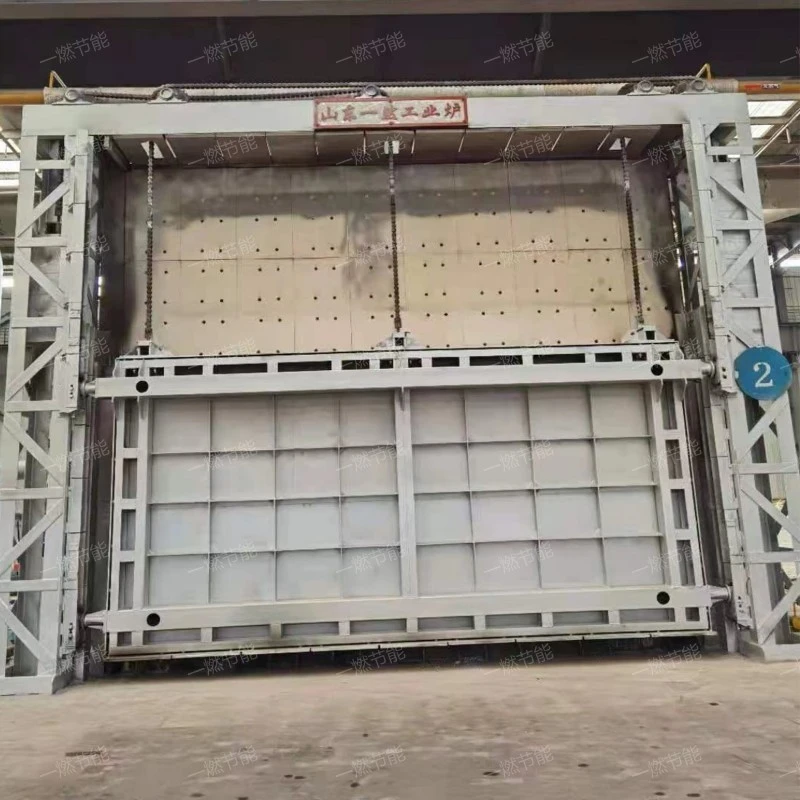

3、Large scale stepper industrial furnace picture

Various specifications and models of Large scale stepper industrial furnace are displayed for our customers to visit.。

Large scale stepper industrial furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

4、Working principle of Large scale stepper industrial furnace

Large scale stepper industrial furnacein the course of work,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.,widely used in aerospace, shipping, building materials, chemical industry, surface treatment and other fields,It is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,super quality and competitive price。

Large scale stepper industrial furnace

5、Structural characteristics of Large scale stepper industrial furnace

The Large scale stepper industrial furnace has the following structure

- convection chamber

- Waste heat recovery system

- Radiation chamber

- furnace chamber

- combustor

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

The heat load of the main place for Large scale stepper industrial furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

A space for holding metallic materials for heating.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Large scale stepper industrial furnace

6、Large scale stepper industrial furnace quotation

The Large scale stepper industrial furnace price is introduced as follows:

- Product technology

- market quotation

- model

- After-sales service level

- Sales model

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

Market supply and demand is the inevitable law of market development, with more market supply, less demand and lower product prices; The market supply is small, and people's demand is large. "Things are scarce and expensive", the product price will increase accordingly, and the price of One-combustion energy saving Large scale stepper industrial furnace will also conform to this market law.

Customer needs are different, so the required product models will be different. Different product models and different performances will naturally lead to different Large scale stepper industrial furnace prices.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Large scale stepper industrial furnace price and service can meet the actual needs of customers.

One-combustion energy saving Large scale stepper industrial furnace manufacturer is a large-scale factory integrating production and sales, the manufacturer produces and sells products directly to customers, without the influence of the price difference between middlemen. The market price of the manufacturer's products is the ex-factory price, and the Large scale stepper industrial furnace price is also low.

Large scale stepper industrial furnace

Large scale stepper industrial furnaceat runtime,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,it has the functions of anneal, Casting heating, temper, heat treatment and hardening and tempering。

Related recommendation

-

Introduction to Reflection Annealing Heating Furnace and forging furnace advantages and features

2025-5-27 -

台车铝合金炉

2023-05-26 -

Introduction to Through type high-temperature quenching heat treatment furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

Introduction to Double through heat treatment furnace and heating furnace structure principle

2025-5-27 -

What is a Fully automatic industrial heating furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

Introduction to Multi tube rotary roasting furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Roller type solid solution quenching furnace and heating furnace advantages and features

2025-5-27 -

Introduction to Large medium temperature electric heating furnace, Trolley electric heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Large gas truck furnace, advantages, characteristics and principles of heating furnace

2025-5-27 -

Introduction to Tubular roasting furnace, Forging furnace specifications, model parameters

2025-5-27