What is a Plate chain quenching heat treatment furnace? Introduction to the advantages and characteristics of forging furnace functions

Plate chain quenching heat treatment furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,it has the structure of furnace chamber, Radiation chamber, ventilation system, recovery of waste heat and convection chamber,multifunctional, with functions such as Casting heating, temper, heat treatment, normalizing and hardening and tempering,has been favored by more and more customers.。

1、Brief introduction of Plate chain quenching heat treatment furnace

Plate chain quenching heat treatment furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,it is widely used inshipping,Machinery manufacturing,chemical industry,building materials,electron and other industries,is based on One-combustion energy saving is a Plate chain quenching heat treatment furnace newly developed by One-combustion energy saving。

Plate chain quenching heat treatment furnace

2、Advantages of Plate chain quenching heat treatment furnace principle

Plate chain quenching heat treatment furnaceat work,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,the product looks beautiful.,it has the functions of quench, Casting heating, temper, anneal and normalizing,Mainly used forMetal forging heating,Energy conservation and environmental protection,Improve production efficiency,Metal heat treatment andMetal melting and casting,is a common Plate chain quenching heat treatment furnace。

Plate chain quenching heat treatment furnace

3、Plate chain quenching heat treatment furnace function

Plate chain quenching heat treatment furnacemultifunctional, with functions such as hardening and tempering, Forging heating, heat treatment, quench and normalizing,is a popular Plate chain quenching heat treatment furnace,the principle is simple.Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,It has a wide range of uses, including Metal tempering, Metal heat treatment, Energy conservation and environmental protection, Improve production efficiency and Metal forging heating,It has the functions of Metal melting and casting, Metal forging heating, Improve production efficiency, Metal melting and casting and Metal heat treatment。

Plate chain quenching heat treatment furnace

4、Plate chain quenching heat treatment furnace use

The purpose of Plate chain quenching heat treatment furnace is introduced as follows:

- Metal heat treatment

- Metal tempering

- Metal forging heating

- Metal heat treatment

- Metal forging heating

In addition to forging heating, Plate chain quenching heat treatment furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

By properly heating and cooling the metal material, the Plate chain quenching heat treatment furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

The Plate chain quenching heat treatment furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

In addition to forging heating, Plate chain quenching heat treatment furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

The Plate chain quenching heat treatment furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

Plate chain quenching heat treatment furnace

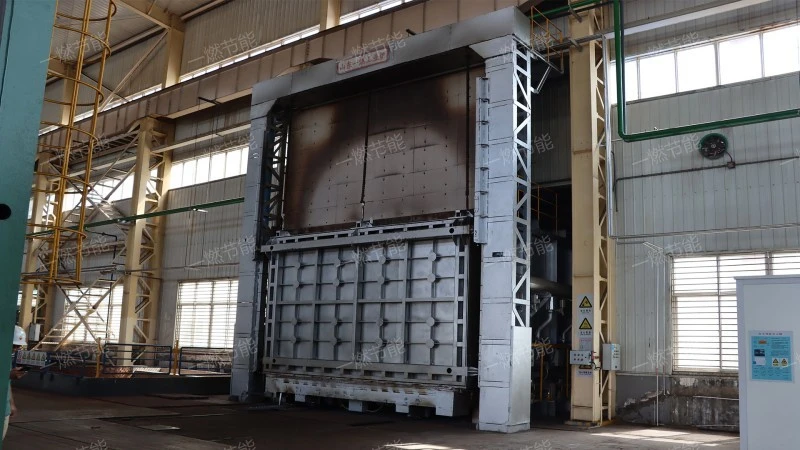

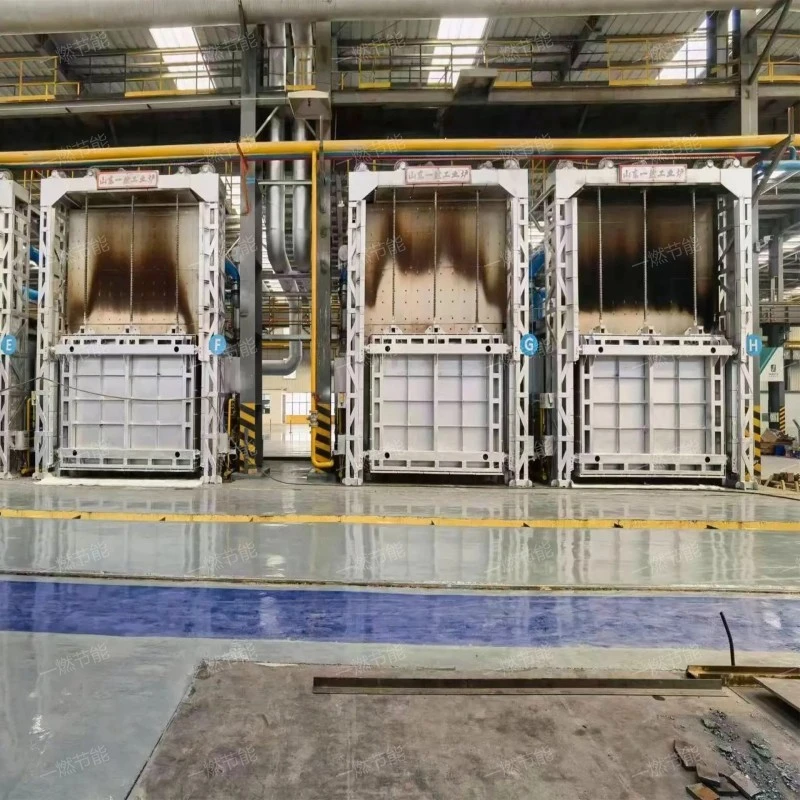

5、Plate chain quenching heat treatment furnace real beat

High-definition picture shooting for various Plate chain quenching heat treatment furnace, all-round display, exquisite appearance, excellent quality and trustworthy.。

Plate chain quenching heat treatment furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

6、One-combustion energy saving's strength

The company has many years of Plate chain quenching heat treatment furnace manufacturing experience, large scale and strong strength.。

One-combustion energy saving

Plate chain quenching heat treatment furnaceat runtime,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,is a Plate chain quenching heat treatment furnace。

Related recommendation

-

What is a Resistance heating reduction annealing furnace? Trolley electric furnace specifications, models, and parameters

2025-5-27 -

Introduction to Quenching furnace chamber type, introduction to forging furnace advantages and characteristics

2025-5-27 -

Introduction to Chain plate continuous heat treatment furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

Introduction to Flue gas denitrification system for forging industry, introduction to SCR denitration function advantages and characteristics

2025-5-27 -

What is a Rotary tube roasting furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

Introduction to Large box furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

航天用电阻炉

2023-04-13 -

Introduction to Double door trolley forging furnace, introduction to heating furnace function advantages and characteristics

2025-5-27 -

What is a Multi tube continuous bright annealing furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

Introduction to Regenerative natural gas through heating furnace and Forging furnace structure principle

2025-5-27