What is a Isothermal well tube furnace? Introduction to the principle of forging furnace structure

Isothermal well tube furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,features include Easy to maintain, Stable and reliable, Strong adaptability, Easy to control and Strong adaptability,the advantage is Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials.、Usually equipped with intelligent control system, it can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.、Natural gas is mainly used as fuel, but some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.、Using regenerative combustion system or advanced burner design can realize the uniform distribution of temperature in the furnace, ensure the uniform heating of metal materials and improve product quality.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.,the product looks atmospheric.,was developed and designed by One-combustion energy saving。

1、Brief introduction of Isothermal well tube furnace

Isothermal well tube furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,it is an ideal choice for customers to buy Isothermal well tube furnace。

Isothermal well tube furnace

2、Functional advantages of Isothermal well tube furnace

Isothermal well tube furnaces have the following advantages.

- Extend the service life of equipment

- Wide application range

- Efficient combustion

- Intelligent control

- Reduce operating costs

The Isothermal well tube furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The Isothermal well tube furnace is suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.

The Isothermal well tube furnace adopts advanced combustion technology and control system, which can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.

The Isothermal well tube furnace is usually equipped with an intelligent control system, which can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.

The efficient combustion and waste heat recovery system of the Isothermal well tube furnace can significantly reduce energy consumption, thus reducing operating costs.

Isothermal well tube furnace

3、Isothermal well tube furnace explanation video

Speak directly with facts on the spot。

Isothermal well tube furnace

As you can see from the live video.,One-combustion energy saving Stable and reliable,energy-efficient,energy saving and environmental protection,Easy to maintain,energy-efficient。

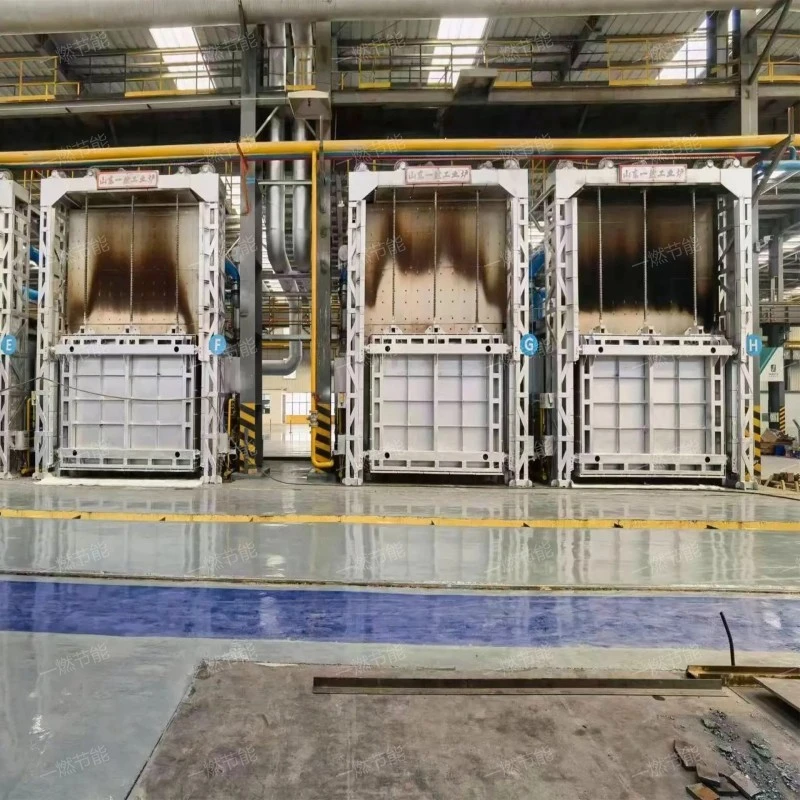

4、On-site real shot of Isothermal well tube furnace

High-definition map of Isothermal well tube furnace is displayed, and the high-definition map of factory area is taken by One-combustion energy saving for reference of our customers.。

Isothermal well tube furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Working principle of Isothermal well tube furnace

Isothermal well tube furnacethe principle is simple.Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,it is widely used in shipping, metallurgy, building materials, pharmacy, war industry and other industries,it has the functions of quench, Casting heating, normalizing, hardening and tempering and anneal。

Isothermal well tube furnace

6、Isothermal well tube furnace price

The Isothermal well tube furnace price is introduced as follows:

- market supply and demand

- region

- Manufacturer scale

- product function

- Reasonable cost

Market change is one of the factors that affect the price range greatly. Market change is unstable, but there are certain rules to follow. Market change is caused by other factors, such as economic instability, competition among manufacturers and too big difference between supply and demand. These factors are the core reasons that cause the market to fluctuate greatly, and then it will have a bad impact on prices.

One-combustion energy saving has a geographical advantage, where the transportation is developed, the product transportation cost is low, and the price and consumption level are also low, which provides a good sales environment for Isothermal well tube furnace.

There are many manufacturers of products in Jinan, and the strength, technology and after-sales of each manufacturer are different, so the quotation for Isothermal well tube furnace is naturally different.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The production cost is mainly the purchase of raw materials. One-combustion energy saving attaches great importance to the purchase of raw materials to ensure the comprehensive quality of products. Only excellent raw materials can produce excellent products, and the input cost of raw materials has a direct relationship with the formulation of product prices. Under the premise of ensuring excellent product performance, One-combustion energy saving strives to reduce the input cost of products, and customers are very satisfied with this.

Isothermal well tube furnace

Isothermal well tube furnaceusually used in machinery, Machinery manufacturing, chemical industry, material, electron and other fields,it has the functions of Casting heating, temper, anneal, heat treatment and quench。

Related recommendation

-

Introduction to Heating furnace flue gas denitrification system, SCR denitration system specifications, model parameters

2025-5-27 -

Introduction to Medium temperature locomotive forging heating furnace in the foundry, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

What is a Fully automatic quenching and heating furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

Introduction to Natural gas box type heating furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

Introduction to Double chamber roasting furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

What is a Decarbonization annealing industrial furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

Introduction to Electric heating furnace for trolley heating, Trolley electric heating furnace advantages, characteristics and principles

2025-5-27 -

What is a Roller type heat treatment furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

What is a Multi chamber forging heating furnace? forging furnace specifications, models, and parameters

2025-5-27 -

Introduction to Pit type mold heating furnace, introduction to Forging furnace advantages and characteristics

2025-5-27