Introduction to Catalytic reduction denitrification equipment and SCR flue gas denitrification working principle

Catalytic reduction denitrification equipmentthat is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.,it has the functions of Improve energy efficiency, Promote sustainable development, Promote sustainable development, environmental protection and Improve energy efficiency,is a popular Catalytic reduction denitrification equipment,can be customized according to user's needs.。

1、Brief introduction of Catalytic reduction denitrification equipment

Catalytic reduction denitrification equipmentit refers to the process of removing nitrogen oxides from flue gas to reduce environmental pollution. NOx is a pollutant harmful to the atmospheric environment, which has strong irritation and toxicity, and will lead to environmental problems such as acid rain and photochemical smog, and also endanger human health. The main principle of flue gas denitrification technology is to reduce NOx to nitrogen and water by adding appropriate reducing agent or catalyst in the combustion process or flue gas treatment system, so as to reduce NOx emission.,the main features are Economically feasible, High denitration efficiency, Good selectivity, Less secondary pollution and Mature technology,The price is relatively low.,reliable quality。

Catalytic reduction denitrification equipment

2、Catalytic reduction denitrification equipment function

Catalytic reduction denitrification equipmentmultifunctional, with functions such as Improve working conditions, Promote sustainable development, Improve working conditions, environmental protection and Improve energy efficiency,the main features are Stable operation, Strong adaptability, Strong adaptability, Environmental protection and pollution-free and Promote sustainable development。

Catalytic reduction denitrification equipment

3、Structural advantages of Catalytic reduction denitrification equipment

The Catalytic reduction denitrification equipment has the following structure

- Temperature control and monitoring system

- Flue gas mixing and distribution

- Temperature control and monitoring

- Reducing agent storage and supply system

- control system

It is used to monitor and control the temperature of the reactor to ensure that the chemical reaction is carried out in the optimal temperature range.

The mixed reducing agent and flue gas are fully mixed in the mixing tube and evenly distributed to the catalyst reactor through the distribution system.

The temperature in the catalyst reactor is maintained within the optimal reaction temperature range through the temperature control and monitoring system.

Used to store and supply reducing agent (such as ammonia or urea solution) to the reactor.

The whole Catalytic reduction denitrification equipment is automatically controlled, including the adjustment of reducing agent supply, flue gas flow and temperature, so as to ensure the stable operation of the system and achieve the expected denitrification effect.

Catalytic reduction denitrification equipment

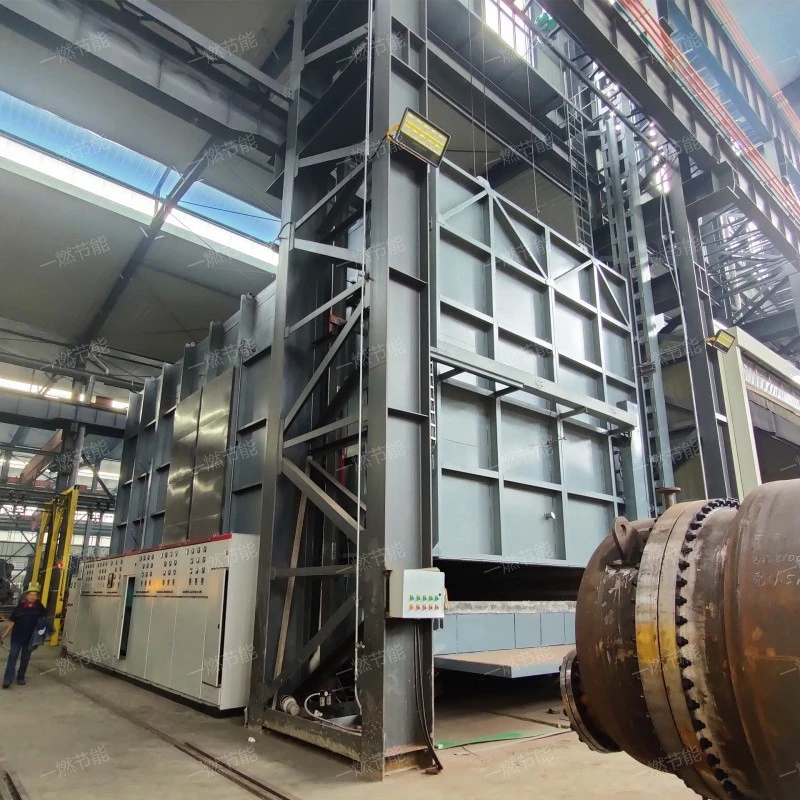

4、Catalytic reduction denitrification equipment working site

On-site aerial photography of Catalytic reduction denitrification equipment。

Catalytic reduction denitrification equipment

As you can see from the live video.,One-combustion energy saving Widely used inenvironmental protection,Improve product quality,Flue gas denitrification,Promote sustainable development,Meet the requirements of environmental protection and so on。

5、Structural characteristics of Catalytic reduction denitrification equipment

The Catalytic reduction denitrification equipment has the following structure

- Reducing agent supply

- Reactor

- Catalytic reduction reaction

- Flue gas mixing and distribution system

- Catalytic reduction reaction

Reducing agents such as liquid pure ammonia or ammonia water (aqueous solution of ammonia) are evaporated and mixed with diluted air or flue gas.

It is the core component of Catalytic reduction denitrification equipment technology, and it is equipped with catalyst to promote the chemical reaction between reductant and NOx.

Under the action of catalyst, the reductant and NOx in flue gas undergo selective catalytic reduction reaction to generate nitrogen and water vapor.

Ensure that the flue gas and reducing agent are fully mixed in the reactor to improve the denitrification efficiency.

Under the action of catalyst, the reductant and NOx in flue gas undergo selective catalytic reduction reaction to generate nitrogen and water vapor.

Catalytic reduction denitrification equipment

6、Catalytic reduction denitrification equipment quotation

The Catalytic reduction denitrification equipment price is introduced as follows:

- quality

- product function

- service

- marketing channel

- regional advantages

The higher the quality of the product, the longer its service life will be, and such products can create more amazing economic value for customers as much as possible. At the same time, customers are quite fond of such products, and One-combustion energy saving's product quality is guaranteed and the price is cost-effective.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Catalytic reduction denitrification equipment manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Catalytic reduction denitrification equipment price can meet the purchasing needs of customers.

Each manufacturer's sales model is different, and the preferential degree of products is also different. Some manufacturers adopt the mode of "thin profit and quick turnover", and the price is relatively cheap. Some manufacturers sell their products at high prices to earn high profits. When purchasing products, they must compare the prices to avoid being cheated.

Geographical location also has a certain influence on the formulation of price, because there is a close relationship between geographical location and transportation cost. Generally, the price of places with superior geographical location will be more fair, which is lower than that of those remote cities. One-combustion energy saving address:Shandong(Province), where the traffic is very developed and convenient, provides a series of conveniences for the distribution of products to a great extent.

Catalytic reduction denitrification equipment

Catalytic reduction denitrification equipmentStructure consists of Flue gas mixing and distribution system, Temperature control and monitoring system, control system, Catalyst reactor, Catalyst supply system and so on,it has the functions of Promote sustainable development, Improve energy efficiency, environmental protection, Improve working conditions and Promote sustainable development。

Related recommendation

-

Introduction to High temperature all fiber gas trolley furnace, how much is the price of the forging furnace?

2025-5-27 -

Introduction to Low temperature oxidation flue gas denitrification system outside the furnace, how much is the price of the SCR denitration system?

2025-5-27 -

Introduction to Heat treatment and tempering trolley heating furnace and heating furnace advantages and features

2025-5-27 -

Introduction to Double ended trolley forging furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

What is a Regenerative natural gas chain heat treatment furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

What is a Fully automatic electric furnace? How much is the price of the Trolley electric heating furnace?

2025-5-27 -

Introduction to Aluminum alloy casting electric heating furnace, introduction to Trolley electric furnace function advantages and characteristics

2025-5-27 -

Introduction to Automatic loading and unloading heating furnace, advantages, characteristics and principles of heating furnace

2025-5-27 -

What is a Preheating burner trolley furnace? Introduction to the advantages and characteristics of the Forging furnace

2025-5-27 -

Introduction to Steel plant ring furnace denitrification equipment and SCR denitration working principle

2025-5-27