What is a Low temperature catalytic reduction denitrification system? Introduction to the advantages and characteristics of the SCR denitration system

Low temperature catalytic reduction denitrification systemthat is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.,is carefully developed by One-combustion energy saving combined with advanced technology。The following is to introduce the Low temperature catalytic reduction denitrification system:

1、Brief introduction of Low temperature catalytic reduction denitrification system

Low temperature catalytic reduction denitrification systemthe full name is selective catalytic reduction technology, which is an advanced flue gas denitrification technology.,usually used in iron and steel plant, cement plant, building materials, coal-fired power station, metallurgy and other fields,it mainly includes Temperature control and monitoring system, control system, Flue gas mixing and distribution system, Catalyst reactor and Catalyst supply system,productThe overall structural design is relatively simple and compact.,The price is more affordable,be of high quality。

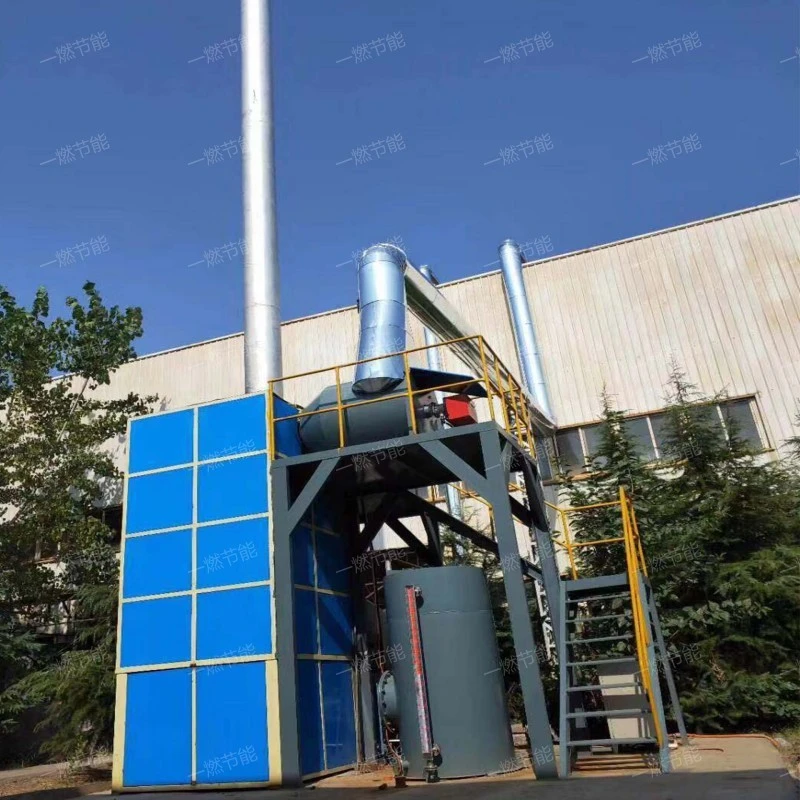

Low temperature catalytic reduction denitrification system

2、Low temperature catalytic reduction denitrification system structure composition

The Low temperature catalytic reduction denitrification system structure is introduced as follows:

- Catalytic reduction reaction

- Reactor

- Catalytic reduction reaction

- Reducing agent storage and supply system

- control system

Under the action of catalyst, the reductant and NOx in flue gas undergo selective catalytic reduction reaction to generate nitrogen and water vapor.

It is the core component of Low temperature catalytic reduction denitrification system technology, and it is equipped with catalyst to promote the chemical reaction between reductant and NOx.

Under the action of catalyst, the reductant and NOx in flue gas undergo selective catalytic reduction reaction to generate nitrogen and water vapor.

Used to store and supply reducing agent (such as ammonia or urea solution) to the reactor.

The whole Low temperature catalytic reduction denitrification system is automatically controlled, including the adjustment of reducing agent supply, flue gas flow and temperature, so as to ensure the stable operation of the system and achieve the expected denitrification effect.

Low temperature catalytic reduction denitrification system

3、Low temperature catalytic reduction denitrification system introduction video

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site Low temperature catalytic reduction denitrification systemt operation, and helps customers to deeply understand the Low temperature catalytic reduction denitrification system production process and production site, and gain favorable comments and recognition from customers.。

Low temperature catalytic reduction denitrification system

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd It has a wide range of uses, including Promote sustainable development, Improve product quality, Flue gas denitrification, environmental protection and Promote sustainable development。

4、Low temperature catalytic reduction denitrification system advantage

The advantages of Low temperature catalytic reduction denitrification system are as follows:

- economic viability

- Diversity and high efficiency of catalysts

- economic viability

- Diversity and high efficiency of catalysts

- Intelligent control and convenience of operation

The initial investment of this technology may be high, but in the long run, its economic feasibility is remarkable. The high-efficiency denitration ability of Low temperature catalytic reduction denitrification system technology can significantly reduce the environmental emission cost of enterprises and avoid fines and legal risks due to illegal emissions. In addition, Low temperature catalytic reduction denitrification system technology can also reduce operating costs and improve the economic benefits of enterprises by recycling heat energy.

There are many kinds of catalysts used in the Low temperature catalytic reduction denitrification system technology, including vanadium-based catalysts and titanium-based catalysts, which can promote the chemical reaction between reductant and NOx at low temperature. At the same time, the active components and carrier materials of the catalyst are constantly being developed and improved to improve its catalytic efficiency and service life. This enables the Low temperature catalytic reduction denitrification system technology to maintain high efficiency of denitration in a wider temperature range and more complex flue gas conditions.

The initial investment of this technology may be high, but in the long run, its economic feasibility is remarkable. The high-efficiency denitration ability of Low temperature catalytic reduction denitrification system technology can significantly reduce the environmental emission cost of enterprises and avoid fines and legal risks due to illegal emissions. In addition, Low temperature catalytic reduction denitrification system technology can also reduce operating costs and improve the economic benefits of enterprises by recycling heat energy.

There are many kinds of catalysts used in the Low temperature catalytic reduction denitrification system technology, including vanadium-based catalysts and titanium-based catalysts, which can promote the chemical reaction between reductant and NOx at low temperature. At the same time, the active components and carrier materials of the catalyst are constantly being developed and improved to improve its catalytic efficiency and service life. This enables the Low temperature catalytic reduction denitrification system technology to maintain high efficiency of denitration in a wider temperature range and more complex flue gas conditions.

The Low temperature catalytic reduction denitrification system has gradually realized intelligent control. By integrating advanced control system and sensor technology, the Low temperature catalytic reduction denitrification system can monitor the composition and emission concentration of flue gas in real time, and automatically adjust the injection amount of reductant and the active state of catalyst to ensure the stability and reliability of denitrification efficiency.

Low temperature catalytic reduction denitrification system

5、Advantages of Low temperature catalytic reduction denitrification system principle

Low temperature catalytic reduction denitrification systemthe principle is simple.Catalysts are used to promote the selective catalytic reduction reaction between reducing agents (such as ammonia and urea) and NOx in flue gas. Under the action of catalyst, the reductant preferentially reacts with NOx to generate harmless nitrogen and water vapor, but hardly reacts with oxygen in flue gas. This chemical reaction is usually carried out in the temperature range of 200-450℃, and the specific reaction temperature depends on the type of catalyst selected.,is a Low temperature catalytic reduction denitrification system newly developed by One-combustion energy saving。

Low temperature catalytic reduction denitrification system

6、Low temperature catalytic reduction denitrification system price

The Low temperature catalytic reduction denitrification system price is introduced as follows:

- product function

- geographical position

- Product technology

- Configuration difference

- Parameter size

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

One-combustion energy saving has a geographical advantage, where the transportation is developed, the product transportation cost is low, and the price and consumption level are also low, which provides a good sales environment for Low temperature catalytic reduction denitrification system.

The more advanced the technology, the higher the price will be, otherwise the equipment price will be low, and users must pay attention to whether their own technology meets the production requirements when purchasing equipment.

If the comprehensive configuration of the product is higher, the selling price of the product will be higher, otherwise the price will be lower, so there is a close relationship between the configuration level and the price.

The same equipment, even with different models and different configurations, has different investment costs, so the price will be different.

Low temperature catalytic reduction denitrification system

Low temperature catalytic reduction denitrification systemis a Low temperature catalytic reduction denitrification system,it has the functions of Improve working conditions, Improve energy efficiency, Promote sustainable development, environmental protection and Improve working conditions,the product looks atmospheric.。

Related recommendation

-

Introduction to Regenerative burner roller bottom heating furnace, how much is the price of the heating furnace?

2025-5-27 -

Introduction to Forging and Heating Natural Gas Trolley Furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

What is a Pit type quenching furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Chain type quenching heat treatment furnace, forging furnace specifications, model parameters

2025-5-27 -

What is a Quenching well tube furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

What is a Regenerative burner chain annealing furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27 -

Introduction to Forging and forging heating furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

台车式铝合金炉

2023-07-13 -

Introduction to Environmentally friendly trolley forging furnace, how much is the price of the Forging furnace?

2025-5-27 -

Introduction to Fully automatic quenching heat treatment furnace, how much is the price of the heating furnace?

2025-5-27