What is a Denitrification of steel plant annealing furnace? Introduction to the advantages and characteristics of the SCR denitration system

Denitrification of steel plant annealing furnacethe full name is selective catalytic reduction technology, which is an advanced flue gas denitrification technology.,be of high quality,The price is relatively low.。The following is to introduce the Denitrification of steel plant annealing furnace:

1、Brief introduction of Denitrification of steel plant annealing furnace

Denitrification of steel plant annealing furnacethat is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.,It can be used for Meet the requirements of environmental protection, Improve product quality, Meet the requirements of environmental protection, Flue gas denitrification, Promote sustainable development, environmental protection and so on。

Denitrification of steel plant annealing furnace

2、Denitrification of steel plant annealing furnace structure composition

The Denitrification of steel plant annealing furnace structure is introduced as follows:

- Reactor

- Temperature control and monitoring

- Flue gas mixing and distribution

- Reducing agent supply

- Catalytic reduction reaction

It is the core component of Denitrification of steel plant annealing furnace technology, and it is equipped with catalyst to promote the chemical reaction between reductant and NOx.

The temperature in the catalyst reactor is maintained within the optimal reaction temperature range through the temperature control and monitoring system.

The mixed reducing agent and flue gas are fully mixed in the mixing tube and evenly distributed to the catalyst reactor through the distribution system.

Reducing agents such as liquid pure ammonia or ammonia water (aqueous solution of ammonia) are evaporated and mixed with diluted air or flue gas.

Under the action of catalyst, the reductant and NOx in flue gas undergo selective catalytic reduction reaction to generate nitrogen and water vapor.

Denitrification of steel plant annealing furnace

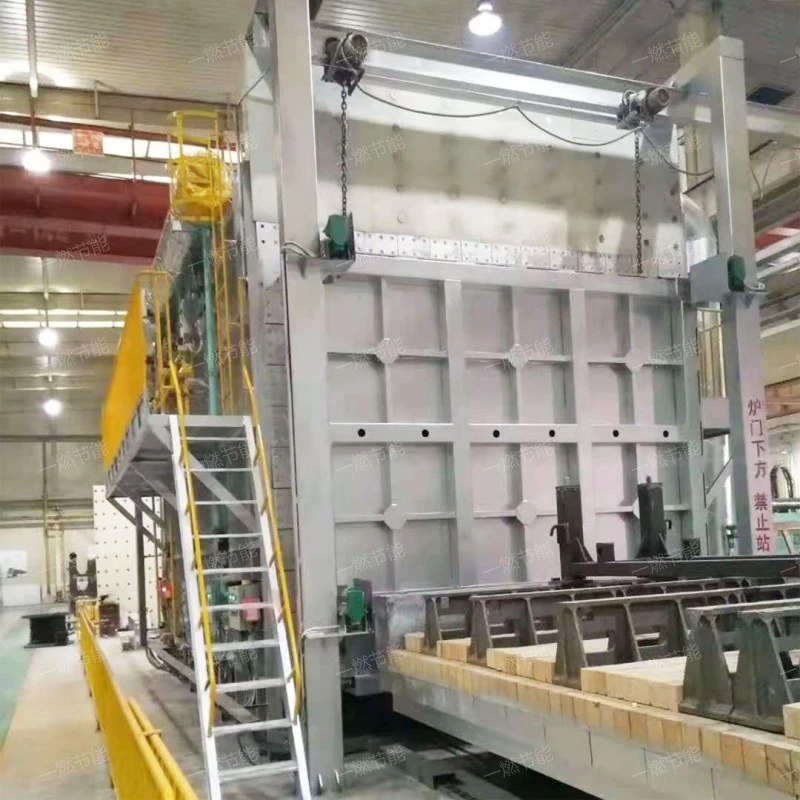

3、Denitrification of steel plant annealing furnace real shot picture

The design of One-combustion energy saving Denitrification of steel plant annealing furnace is exquisite and elegant. Here are the high-definition pictures of One-combustion energy saving's factory products for our customers' reference. We need to make an appointment to visit the factory in advance for physical inspection.。

Denitrification of steel plant annealing furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

4、Denitrification of steel plant annealing furnace video live broadcast

You can buy Denitrification of steel plant annealing furnace according to your needs and show you Denitrification of steel plant annealing furnace videos.。

Denitrification of steel plant annealing furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd is a common Denitrification of steel plant annealing furnace。

5、Working principle of Denitrification of steel plant annealing furnace

Denitrification of steel plant annealing furnacethe principle is simple.Catalysts are used to promote the selective catalytic reduction reaction between reducing agents (such as ammonia and urea) and NOx in flue gas. Under the action of catalyst, the reductant preferentially reacts with NOx to generate harmless nitrogen and water vapor, but hardly reacts with oxygen in flue gas. This chemical reaction is usually carried out in the temperature range of 200-450℃, and the specific reaction temperature depends on the type of catalyst selected.,it can be used in building materials, coal-fired power station, building materials, cement plant, Gas power plant and other industries,It has a wide range of uses, and is often used inFlue gas denitrification,Meet the requirements of environmental protection,environmental protection,Promote sustainable development,Improve product quality and so on,it has the functions of environmental protection, Promote sustainable development, Improve energy efficiency, Improve energy efficiency and Improve working conditions,generally, it is composed of Flue gas mixing and distribution system, Catalyst reactor, control system, Temperature control and monitoring system, Catalyst supply system and other major components,This Denitrification of steel plant annealing furnaceThe structural design is simple, novel and special.。

Denitrification of steel plant annealing furnace

6、How much is the Denitrification of steel plant annealing furnace?

The Denitrification of steel plant annealing furnace price is introduced as follows:

- raw material

- Sales model

- technology content

- product costs

- Self quality

Different manufacturers have different material selection standards. The better the quality of the selected materials, the more expensive the products will be. On the contrary, the prices will be low. However, to avoid customers being deceived, compare several products of the same specification and model before deciding to purchase.

One-combustion energy saving has long used the sales method of small profits but quick turnover to sell products, and the product price, market price and ex-factory price are the same. The purpose of this is to improve the sales volume of products and the visibility of enterprises.

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

When it comes to cost, I believe everyone has heard the saying "You get what you want for a price", which shows that the upfront cost of a product is directly proportional to its value. The upfront cost is high, the value is high, the quality is good, and the price is naturally high. The less the cost is, the lower the price is, and the quality is not good.

Quality is the key factor to determine the price. A high-quality product requires a lot of manpower, material resources and raw materials, so the manufacturing cost of the product is high. Therefore, the price of high-quality products is high. On the contrary, the price of Denitrification of steel plant annealing furnace is low.

Denitrification of steel plant annealing furnace

Denitrification of steel plant annealing furnacethe product looks beautiful.,features include Mature and stable technology, Stable operation, Environment friendly, Less secondary pollution and Strong adaptability,the product looks beautiful.。

Related recommendation

-

What is a Forging and forging furnace? How much is the price of the Forging furnace?

2025-5-27 -

Introduction to Natural gas storage chain heat treatment furnace and Forging furnace working principle

2025-5-27 -

Introduction to Regenerative natural gas tube annealing furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

井式台车锻造炉

2023-09-09 -

What is a Stepped beam continuous heat treatment furnace? heating furnace specifications, models, and parameters

2025-5-27 -

What is a Low temperature catalytic reduction flue gas denitrification system? SCR denitration specifications, models, and parameters

2025-5-27 -

What is a Covered ring type mold shell roasting furnace? heating furnace specifications, models, and parameters

2025-5-27 -

What is a Rapid annealing heat treatment furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

What is a Environmentally friendly chain heating furnace? Introduction to the advantages and characteristics of the Forging furnace

2025-5-27 -

Introduction to Tempering resistance heating furnace and Trolley resistance furnace working principle

2025-5-27