What is a Industrial heating furnace denitrification? Introduction to the advantages and characteristics of SCR denitration system functions

Industrial heating furnace denitrificationthe full name is selective catalytic reduction technology, which is an advanced flue gas denitrification technology.,is a common Industrial heating furnace denitrification,support customization。

1、Brief introduction of Industrial heating furnace denitrification

Industrial heating furnace denitrificationis an efficient, stable and environment-friendly flue gas denitrification technology.,It has a wide range of uses, including Improve product quality, environmental protection, Flue gas denitrification, Meet the requirements of environmental protection and Promote sustainable development,the product looks atmospheric.,Less secondary pollution,Environment friendly,Mature technology,Mature and stable technology,Efficient denitration,is an advanced Industrial heating furnace denitrification developed by our company in combination with the actual situation of the industry。

Industrial heating furnace denitrification

2、Industrial heating furnace denitrification principle

Industrial heating furnace denitrificationin the course of work,Catalysts are used to promote the selective catalytic reduction reaction between reducing agents (such as ammonia and urea) and NOx in flue gas. Under the action of catalyst, the reductant preferentially reacts with NOx to generate harmless nitrogen and water vapor, but hardly reacts with oxygen in flue gas. This chemical reaction is usually carried out in the temperature range of 200-450℃, and the specific reaction temperature depends on the type of catalyst selected.,it has the functions of environmental protection, Promote sustainable development, environmental protection, Promote sustainable development and Improve energy efficiency,reliable quality。

Industrial heating furnace denitrification

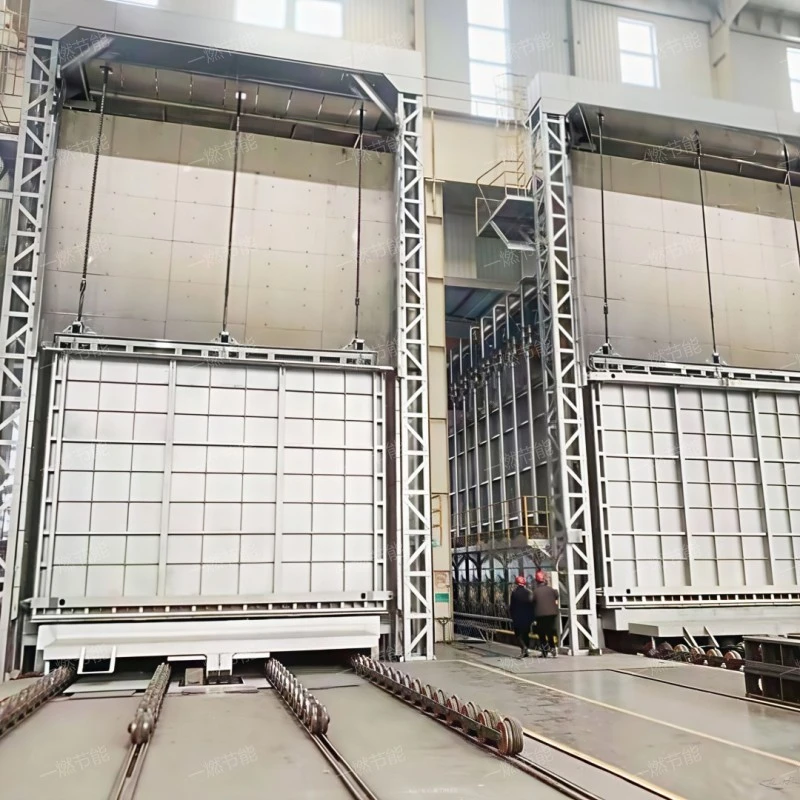

3、Industrial heating furnace denitrification HD real picture

Its appearance design is exquisite and elegant. The following is a high-definition picture of the factory for One-combustion energy saving's customers to choose and buy. You can contact online customer service at any time, make an appointment to visit the factory and take a shuttle bus from One-combustion energy saving.。

Industrial heating furnace denitrification

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

4、Industrial heating furnace denitrification function

Industrial heating furnace denitrificationmultifunctional, with functions such as Improve working conditions, environmental protection, Improve energy efficiency, Promote sustainable development and Improve working conditions,at runtime,Ammonia gas or other suitable reducing agent (such as urea aqueous solution) is sprayed into the flue gas upstream of the catalyst at high temperature. Under the action of catalyst, the reducing agent selectively reacts with nitrogen oxides (NOx) in flue gas to generate pollution-free nitrogen and water vapor. Because NH3 is selective, it only reacts with NOx and basically does not react with O2, so this technology is called selective catalytic reduction denitrification.,Environmental protection and pollution-free,Strong adaptability,Stable operation,Strong adaptability,energy saving and environmental protection,it is an ideal choice for customers to buy Industrial heating furnace denitrification。

Industrial heating furnace denitrification

5、Industrial heating furnace denitrification use

Industrial heating furnace denitrificationIt has a wide range of uses, and is often used inImprove product quality,environmental protection,Meet the requirements of environmental protection,Promote sustainable development,Flue gas denitrification and so on。

Industrial heating furnace denitrification

6、Industrial heating furnace denitrification price advantage

The Industrial heating furnace denitrification price is introduced as follows:

- cost of production

- product quality

- Manufacturer's sales model

- Configuration difference

- raw material

Cost is a direct and fundamental factor that affects the price of Industrial heating furnace denitrification. The manufacturing cost is reflected in the capital investment spent on raw materials, labor and technology, which is high in cost, high in Industrial heating furnace denitrification price, low in cost and low in price.

Usually, the price of good quality products will be higher, because the product has higher technical content and more costs in raw materials and labor, but the performance of such products is higher and the profits will be higher. On the contrary, the price of ordinary quality products will be relatively lower, but the benefits will be correspondingly poor.

One-combustion energy saving Industrial heating furnace denitrification manufacturer is a specialized manufacturer of Industrial heating furnace denitrification, the manufacturer produces and sells products directly to customers, without the influence of the price difference between middlemen. The market price of the manufacturer's products is the ex-factory price, and the Industrial heating furnace denitrification price is also low.

The higher the hardware configuration, the greater the product cost, so the sales price of such products will be higher. One-combustion energy saving pays special attention to the hardware configuration of products, so One-combustion energy saving Industrial heating furnace denitrification has a higher cost performance.

The quality of material selection is one of the main factors that directly affect the Industrial heating furnace denitrification. If the quality of material selection is better, the price may be more expensive. Therefore, customers must first understand the quality of material selection before purchasing products, and then compare whether the quality and price match.

Industrial heating furnace denitrification

Industrial heating furnace denitrificationit has been widely used in coal-fired power station, building materials, Gas power plant, cement plant, cement plant and other industries,is a Industrial heating furnace denitrification。

Related recommendation

-

What is a Gas storage tubular heating furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

Introduction to Low temperature catalyst furnace external flue gas denitrification equipment, SCR flue gas denitrification advantages, characteristics and principles

2025-5-27 -

Introduction to Deep well quenching heating furnace and heating furnace working principle

2025-5-27 -

What is a Resistance trolley furnace? Introduction to the advantages and characteristics of Trolley resistance furnace functions

2025-5-27 -

Introduction to Normalizing electric furnace, how much is the price of the Trolley electric heating furnace?

2025-5-27 -

Introduction to Stepping bottom roasting furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

Introduction to Energy saving and environmentally friendly trolley heating furnace and forging furnace working principle

2025-5-27 -

Introduction to Industrial heating furnace denitrification system, advantages, characteristics and principles of SCR flue gas denitrification

2025-5-27 -

Introduction to Casting trolley forging furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

Introduction to Full fiber medium temperature locomotive heating furnace, introduction to heating furnace function advantages and characteristics

2025-5-27