What is a Resistance heating heat treatment furnace? How much is the price of the Trolley electric heating furnace?

Resistance heating heat treatment furnaceis an industrial furnace that uses electric current to generate heat energy through resistive materials, thus heating workpieces or materials.,features include High flexibility, Environmental protection and safety, Fast heating speed, High thermal efficiency and Low maintenance cost,customizable。The following is to introduce the Resistance heating heat treatment furnace:

1、Brief introduction of Resistance heating heat treatment furnace

Resistance heating heat treatment furnaceis an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.,multifunctional, with functions such as normalizing, quench, heat treatment, anneal and Casting heating,multifunctional, with functions such as Forging heating, hardening and tempering, heat treatment, hardening and tempering and normalizing。

Resistance heating heat treatment furnace

2、Resistance heating heat treatment furnace function

Resistance heating heat treatment furnaceit has the functions of Forging heating, temper, quench, Casting heating and anneal,the product looks beautiful.,it has been widely used in Special material, building materials, electron, machinery, glass and other industries,was developed and designed by One-combustion energy saving。

Resistance heating heat treatment furnace

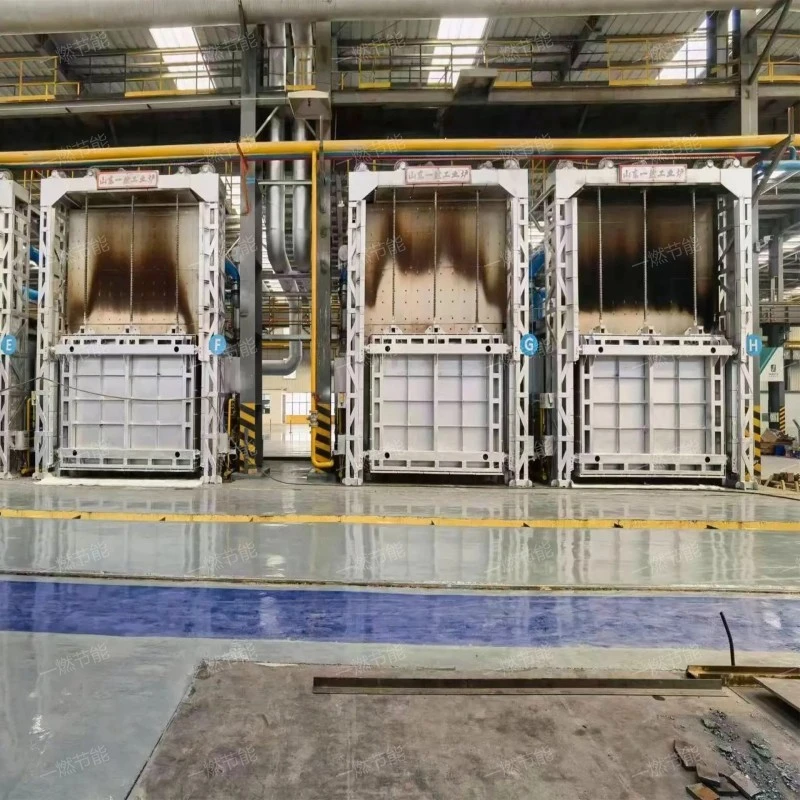

3、Resistance heating heat treatment furnace video live broadcast

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Resistance heating heat treatment furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd It has the functions of Heating before metal forging, normalizing, hardening and tempering, anneal and quench。

4、Resistance heating heat treatment furnace use

The purpose of Resistance heating heat treatment furnace is introduced as follows:

- New material development

- Ceramic and glass industries

- powder metallurgy

- Metal melting and casting

- Metal heat treatment

Used for synthesis and heat treatment of special materials and new materials.

Used for baking and annealing of ceramics and glass.

Used for sintering and heat treatment of powder.

Used for melting low melting point metals and alloys.

Such as quenching, normalizing, annealing, tempering, etc.

Resistance heating heat treatment furnace

5、Resistance heating heat treatment furnace price consultation

The Resistance heating heat treatment furnace price is introduced as follows:

- Manufacturer scale

- Reasonable sales model

- cost of production

- select a qualified person

- product function

Direct selling by manufacturers and sales by middlemen will also affect product prices. There are not too many links among direct selling products, so the cost required by manufacturers is low, and the price of Resistance heating heat treatment furnace is low. Customers can also put products into production in advance. On the contrary, when purchasing products from middlemen, there are not only many links, but also the price of Resistance heating heat treatment furnace is much higher, so customers should choose products directly sold by manufacturers when purchasing.

One-combustion energy saving Resistance heating heat treatment furnace manufacturer is a self-produced and self-selling manufacturer, the manufacturer produces and sells products directly to customers, without the influence of the price difference between middlemen. The market price of the manufacturer's products is the ex-factory price, and the Resistance heating heat treatment furnace price is also low.

The cost of manufacturing Resistance heating heat treatment furnace varies from manufacturer to manufacturer. The higher the cost of manufacturing products, the higher the product price will be. On the other hand, the lower the production cost, the lower the product price, but the quality of products with high production cost is guaranteed, which can reduce the maintenance cost of customers.

The raw materials used by manufacturers of different products will definitely be different. Some manufacturers use good raw materials for processing, and the cost of producing and manufacturing products is definitely high. If the quality of products produced by manufacturers is not guaranteed and the materials used are not very good, then the production cost of products will be low, and the price will be very low.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Resistance heating heat treatment furnace

6、Why choose One-combustion energy saving?

Choosing a suitable Resistance heating heat treatment furnace manufacturer requires comprehensive consideration of many aspects. First of all, we should examine the strength of manufacturers, including production capacity, R&D team and industry experience. Strong manufacturers can better ensure product supply and innovation ability. Secondly, product quality is the key, and it is evaluated by product certification, material selection and manufacturing process to ensure the durability of products. Product performance can not be ignored, so we should choose manufacturers with matching technical parameters, rich types and customized services according to actual needs. After-sales service is equally important. Professional and timely service team, perfect after-sales content and extensive service network can make users worry about nothing. In addition, market reputation is also an important reference. We can understand the reputation and status of manufacturers through customer evaluation, industry reputation and award-winning honor. Finally, it is necessary to analyze the price and cost performance, and on the premise of ensuring the quality and performance, choose a manufacturer with reasonable price and high cost performance, so as to purchase Resistance heating heat treatment furnace products that meet the demand and have good cost performance.。

One-combustion energy saving

Resistance heating heat treatment furnacewidely used inNew material development,glass,electron,pottery and porcelain,chemical industry and other industries,in the course of work,Thermal effect based on current. When current passes through resistive materials (such as resistance wires, resistance bands, etc.), due to the existence of resistance, electric energy will be converted into heat energy, which will make the resistive materials heat up. This heat is then transferred to the workpiece or material in the furnace to achieve the purpose of heating.,the advantage is Strong customization, the Resistance heating heat treatment furnace can be customized according to the actual needs of users, such as heating power, furnace size, temperature control accuracy, etc., to meet the requirements of specific processes.、The maintenance cost is low, the Resistance heating heat treatment furnace structure is relatively simple, the maintenance is relatively convenient, and the failure rate is relatively low, which is helpful to reduce the maintenance cost.、The service life is long, and the key components such as furnace body and electric heating element are made of high quality materials, which has high durability and stability.、The temperature uniformity is good, and the temperature distribution in the Resistance heating heat treatment furnace is relatively uniform, which is helpful to reduce the temperature gradient in the heating process of the workpiece and improve the heating quality.、The temperature control precision is high, and the Resistance heating heat treatment furnace is equipped with advanced temperature control system, which can accurately control the temperature in the furnace and ensure the stability and reliability of the process.。

Related recommendation

-

What is a Top fired forging box type heating furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Full fiber high-temperature trolley forging heating furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

What is a Multi chamber forging heating furnace? forging furnace specifications, models, and parameters

2025-5-27 -

Introduction to Low temperature catalyst furnace external flue gas denitrification equipment, SCR flue gas denitrification advantages, characteristics and principles

2025-5-27 -

Introduction to Galvanized heating furnace and forging furnace advantages and features

2025-5-27 -

What is a Box type resistance furnace? Introduction to the principle of Trolley resistance heating furnace structure

2025-5-27 -

What is a Deep well annealing furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

环形天然气台车炉

2023-08-24 -

What is a Full fiber trolley forging furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

Introduction to Automatic Annealing Furnace, how much is the price of the heating furnace?

2025-5-27