What is a Isothermal forging furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

Isothermal forging furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,The price is low and affordable,modern technology。The following is to introduce the Isothermal forging furnace:

1、Brief introduction of Isothermal forging furnace

Isothermal forging furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,it can be used in building materials, Household necessities, automobile, metallurgy, material and other industries,the product looks beautiful.,it has the functions of Forging heating, hardening and tempering, Forging heating, heat treatment and normalizing,is carefully developed by One-combustion energy saving combined with advanced technology。

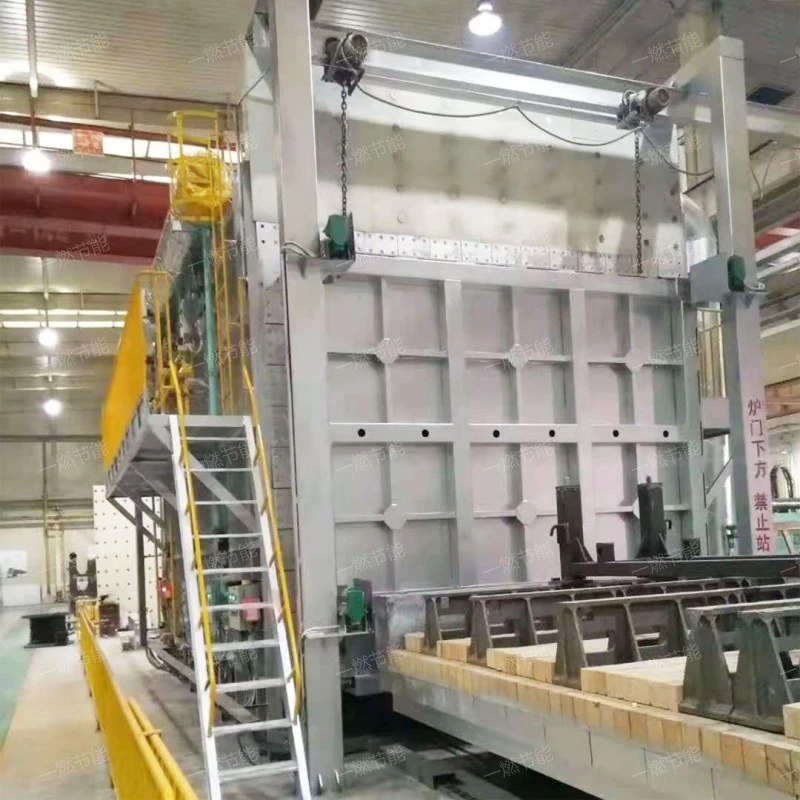

Isothermal forging furnace

2、Isothermal forging furnace function

Isothermal forging furnaceit has the functions of quench, temper, anneal, Casting heating and hardening and tempering。

Isothermal forging furnace

3、Isothermal forging furnace structure

The Isothermal forging furnace structure is introduced as follows:

- Waste heat recovery system

- furnace chamber

- Radiation chamber

- convection chamber

- ventilation system

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

A space for holding metallic materials for heating.

The heat load of the main place for Isothermal forging furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Isothermal forging furnace

4、Introduction of Isothermal forging furnace characteristics

Isothermal forging furnace has the following characteristics

- Easy to maintain

- Efficient heating

- Stable and reliable

- energy saving and environmental protection

- Strong adaptability

The structural design of the Isothermal forging furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The Isothermal forging furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

The Isothermal forging furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

Natural gas is a kind of clean energy, which produces less waste gas and waste smoke after combustion and has little environmental pollution. At the same time, through wall regenerative combustion technology, flue gas waste heat recovery system and other technical means, the Isothermal forging furnace further improves energy utilization efficiency and reduces energy consumption and emissions.

The Isothermal forging furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

Isothermal forging furnace

5、Isothermal forging furnace picture

Overview of high-definition pictures,the product looks atmospheric., different specifications and models。

Isothermal forging furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

6、Isothermal forging furnace price

The Isothermal forging furnace price is introduced as follows:

- select a qualified person

- After-sales service level

- manufacturing cost

- product configuration

- Reasonable sales model

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Isothermal forging furnace price and service can meet the actual needs of customers.

Cost is a direct and fundamental factor that affects the price of Isothermal forging furnace. The manufacturing cost is reflected in the capital investment spent on raw materials, labor and technology, which is high in cost, high in Isothermal forging furnace price, low in cost and low in price.

The difference in Isothermal forging furnace configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

There are direct selling manufacturers and agents in the market. Agents are higher than direct selling manufacturers, mainly because agents get goods from manufacturers, sell them to customers and earn the difference from middlemen, so the natural price is higher.

Isothermal forging furnace

Isothermal forging furnaceis a common Isothermal forging furnace,it is widely used in machinery, shipping, surface treatment, heat treatment, pharmacy and other industries,Simple structure and reliable operation.,the main structure includes recovery of waste heat, combustor, ventilation system, furnace chamber and combustor。

Related recommendation

-

Introduction to Split type annealing heating furnace, forging furnace specifications, model parameters

2025-5-27 -

Introduction to Automatic continuous quenching heating furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Double ended trolley furnace, forging furnace specifications, model parameters

2025-5-27 -

What is a Continuous isothermal quenching industrial furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Electric heating roasting furnace, introduction to Trolley resistance furnace advantages and characteristics

2025-5-27 -

What is a Copper rod heating furnace? How much is the price of the forging furnace?

2025-5-27 -

What is a Gas-fired regenerative walking furnace? How much is the price of the heating furnace?

2025-5-27 -

Introduction to Reflection annealing heat treatment furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

What is a Forging box furnace? How much is the price of the forging furnace?

2025-5-27 -

Introduction to Fully automatic feeding heating furnace and heating furnace working principle

2025-5-27