What is a Automatic feeding, unloading, forging and heating furnace? How much is the price of the heating furnace?

Automatic feeding, unloading, forging and heating furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.。

1、Brief introduction of Automatic feeding, unloading, forging and heating furnace

Automatic feeding, unloading, forging and heating furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,is a popular Automatic feeding, unloading, forging and heating furnace,it is widely used in machinery, petroleum, shipping, material and aerospace。

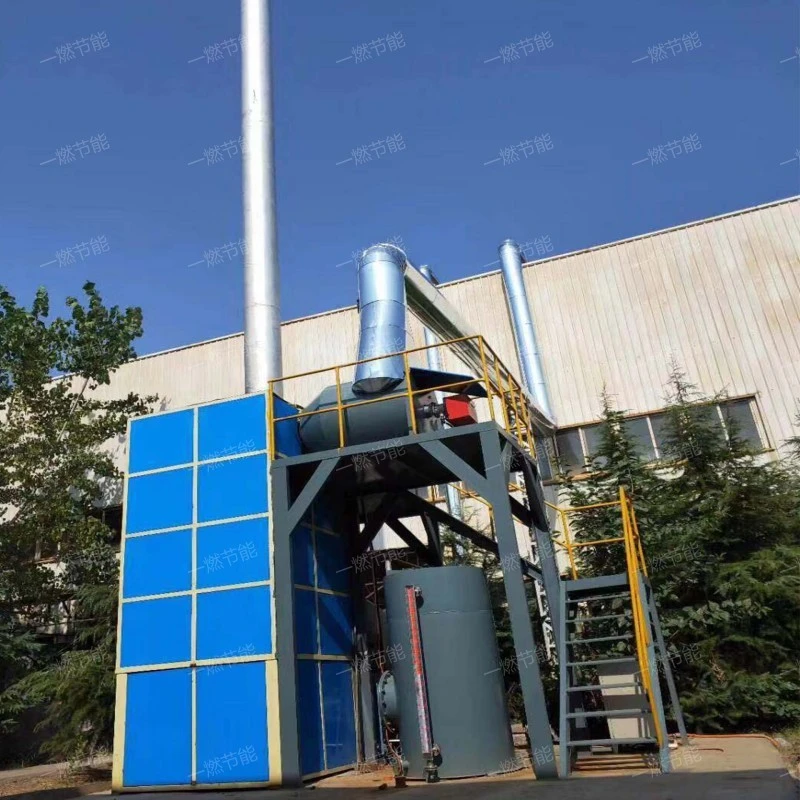

Automatic feeding, unloading, forging and heating furnace

2、Working principle of Automatic feeding, unloading, forging and heating furnace

Automatic feeding, unloading, forging and heating furnacein the course of work,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,Mainly used forMetal forging heating,Improve production efficiency,Metal melting and casting,Metal heat treatment andMetal tempering。

Automatic feeding, unloading, forging and heating furnace

3、Automatic feeding, unloading, forging and heating furnace structure composition

The Automatic feeding, unloading, forging and heating furnace structure is introduced as follows:

- furnace chamber

- combustor

- Waste heat recovery system

- ventilation system

- furnace chamber

A space for holding metallic materials for heating.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Used to recover the exhaust heat of the heating furnace. There are two kinds of recovery methods, one is to recover by preheating combustion air, so that the recovered heat can return to the furnace again; The other is to use another recovery system to recover heat. The former is called air preheating mode, and the latter is usually called waste heat boiler mode.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

A space for holding metallic materials for heating.

Automatic feeding, unloading, forging and heating furnace

4、Automatic feeding, unloading, forging and heating furnace performance advantage

The advantages of Automatic feeding, unloading, forging and heating furnace are as follows:

- Uniform heating

- easy to operate

- Uniform heating

- Wide application range

- Intelligent control

The Automatic feeding, unloading, forging and heating furnace adopts regenerative combustion system or advanced burner design, which can realize uniform distribution of temperature in the furnace, ensure uniform heating of metal materials and improve product quality.

The operation interface of the Automatic feeding, unloading, forging and heating furnace is friendly and easy for operators to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.

The Automatic feeding, unloading, forging and heating furnace adopts regenerative combustion system or advanced burner design, which can realize uniform distribution of temperature in the furnace, ensure uniform heating of metal materials and improve product quality.

The Automatic feeding, unloading, forging and heating furnace is suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.

The Automatic feeding, unloading, forging and heating furnace is usually equipped with an intelligent control system, which can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.

Automatic feeding, unloading, forging and heating furnace

5、Automatic feeding, unloading, forging and heating furnace price concessions

The Automatic feeding, unloading, forging and heating furnace price is introduced as follows:

- Product technology

- Proper management mode

- regional difference

- brand

- quality

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

Each manufacturer's sales model is different, and the preferential degree of products is also different. Some manufacturers adopt the mode of "thin profit and quick turnover", and the price is relatively cheap. Some manufacturers sell their products at high prices to earn high profits. When purchasing products, they must compare the prices to avoid being cheated.

The consumption level in different regions is different, which directly affects the equipment cost investment. Generally speaking, the higher the consumption level, the higher the cost of production equipment, and the higher the cost investment, the higher the price naturally.

Different brands of products in the same series have more or less differences in product prices, and different brands of Automatic feeding, unloading, forging and heating furnace have more or less differences in price.

One-combustion energy saving attaches great importance to the quality of products, which can be reflected in the manufacturing process of Automatic feeding, unloading, forging and heating furnace and the handling of details. Therefore, there is also a close relationship between quality and price. The price of high-quality products will naturally be high, and vice versa.

Automatic feeding, unloading, forging and heating furnace

6、One-combustion energy saving service

Service has a starting point, and satisfaction has no end. One-combustion energy saving provides services such as free design scheme before sale, free installation and debugging of products during sale, and regular return visits after sale to solve customer problems in time. If you have special requirements for products, manufacturers also support tailor-made.。

One-combustion energy saving

Automatic feeding, unloading, forging and heating furnaceusually used in building materials, Machinery manufacturing, Machinery manufacturing, pharmacy, electron and other fields,multifunctional, with functions such as hardening and tempering, quench, Casting heating, heat treatment and temper。

Related recommendation

-

What is a Electric heating low-temperature tempering furnace? Introduction to the principle of Trolley resistance heating furnace structure

2025-5-27 -

Introduction to Regenerative natural gas trolley forging furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

What is a Energy saving and environmentally friendly tube furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

Introduction to Preheating burner trolley forging heating furnace, how much is the price of the Forging furnace?

2025-5-27 -

Introduction to Industrial tube annealing furnace, advantages, characteristics and principles of heating furnace

2025-5-27 -

天然气烧嘴

2023-03-18 -

Introduction to Preheater type heating furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to SCR medium temperature denitrification and SCR flue gas denitrification working principle

2025-5-27 -

What is a Rotary bottom heat treatment heating furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

台车固溶炉

2023-05-10