Introduction to Regenerative box type heating furnace and heating furnace working principle

Regenerative box type heating furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,structure mainly includes: convection chamber, recovery of waste heat, combustor, ventilation system, Radiation chamber and so on,This productThe overall structural design is simple and novel.,at runtime,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,is based on One-combustion energy saving is a Regenerative box type heating furnace newly developed by One-combustion energy saving。

1、Brief introduction of Regenerative box type heating furnace

Regenerative box type heating furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,the product looks atmospheric.,support customization。

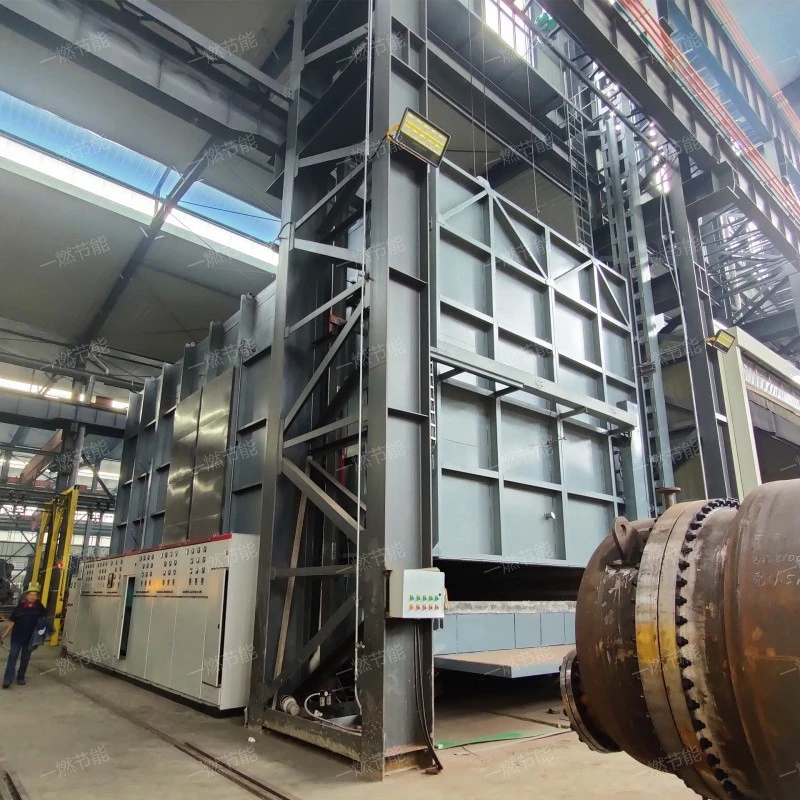

Regenerative box type heating furnace

2、Regenerative box type heating furnace video detail

Speak directly with facts on the spot。

Regenerative box type heating furnace

As you can see from the live video.,One-combustion energy saving It is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.。

3、Regenerative box type heating furnace function

Regenerative box type heating furnacemultifunctional, with functions such as Forging heating, normalizing, quench, hardening and tempering and Forging heating,It can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.、Efficient combustion and waste heat recovery system can significantly reduce energy consumption, thus reducing operating costs.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、The use of clean and environmentally friendly natural gas as fuel effectively avoids the adverse effects of chemical reactions between impurities such as coal-fired furnaces and forgings during heating. At the same time, natural gas has high calorific value and high combustion temperature, and the combustion temperature can be further increased by preheating air and fuel. In addition, the gas forging heating furnace also has good heat loss control ability and intelligent control system, which can accurately adjust the ratio of air to natural gas, ensure full combustion of natural gas, and reduce mechanical incomplete combustion and chemical incomplete combustion.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.,the product looks beautiful.,the main features are Easy to control, Stable and reliable, energy saving and environmental protection, energy-efficient and Easy to maintain,it is an ideal choice for customers to buy Regenerative box type heating furnace。

Regenerative box type heating furnace

4、Introduction of Regenerative box type heating furnace characteristics

Regenerative box type heating furnace has the following characteristics

- Easy to maintain

- Strong adaptability

- Easy to control

- Efficient heating

- Easy to maintain

The structural design of the Regenerative box type heating furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The Regenerative box type heating furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

The combustion system and ventilation system of the Regenerative box type heating furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

The Regenerative box type heating furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

The structural design of the Regenerative box type heating furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

Regenerative box type heating furnace

5、How much is the Regenerative box type heating furnace?

The Regenerative box type heating furnace price is introduced as follows:

- marketing channel

- deploy

- product function

- After-sales service level

- quality

Each manufacturer's sales model is different, and the preferential degree of products is also different. Some manufacturers adopt the mode of "thin profit and quick turnover", and the price is relatively cheap. Some manufacturers sell their products at high prices to earn high profits. When purchasing products, they must compare the prices to avoid being cheated.

Configuration refers to the hardware composition of the product, which mainly includes material selection, parts selection, etc. The higher the overall configuration of the product, the higher the price of the Regenerative box type heating furnace, which is beyond doubt. One-combustion energy saving makes every product with great care in the attitude of being highly responsible to customers, so the price of One-combustion energy saving Regenerative box type heating furnace is reasonable for products with the same configuration.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Regenerative box type heating furnace manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Regenerative box type heating furnace price can meet the purchasing needs of customers.

The quality of products provided by different manufacturers is different, so their prices will be different. Generally, large manufacturers provide products with higher quality, and the cost of technology and materials is more, so the price is relatively high. However, such products have better use effect and can bring longer-term benefits to customers.

Regenerative box type heating furnace

6、Company discount

Regenerative box type heating furnace is a new type of heating furnace introduced by Shandong yiran energy-saving environment protection co., ltd manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for material and other industries. Now consult One-combustion energy savingproduction-manufacturing的Regenerative box type heating furnace, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

One-combustion energy saving

Regenerative box type heating furnacein the course of work,The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,it has the functions of Casting heating, anneal, normalizing, heat treatment and temper。

Related recommendation

-

What is a Step furnace denitrification? Introduction to the advantages and characteristics of the SCR denitration system

2025-5-27 -

Introduction to Deep well heating furnace and Forging furnace structure principle

2025-5-27 -

What is a Direct fired annealing furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27 -

Introduction to Heat treatment heating electric furnace, Trolley electric heating furnace advantages, characteristics and principles

2025-5-27 -

What is a Natural gas chain annealing furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Regenerative through heating furnace and Forging furnace working principle

2025-5-27 -

What is a Flat steel heating furnace? Introduction to the advantages and characteristics of heating furnace functions

2025-5-27 -

Introduction to Circular stepper industrial furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Energy saving electric heating furnace and Trolley electric furnace advantages and features

2025-5-27 -

What is a Environmentally friendly chain heating furnace? Introduction to the advantages and characteristics of the Forging furnace

2025-5-27