Introduction to Automatic temperature control tube quenching furnace, forging furnace specifications, model parameters

Automatic temperature control tube quenching furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,is a kind of Automatic temperature control tube quenching furnace manufactured by One-combustion energy saving。The following is to introduce the Automatic temperature control tube quenching furnace:

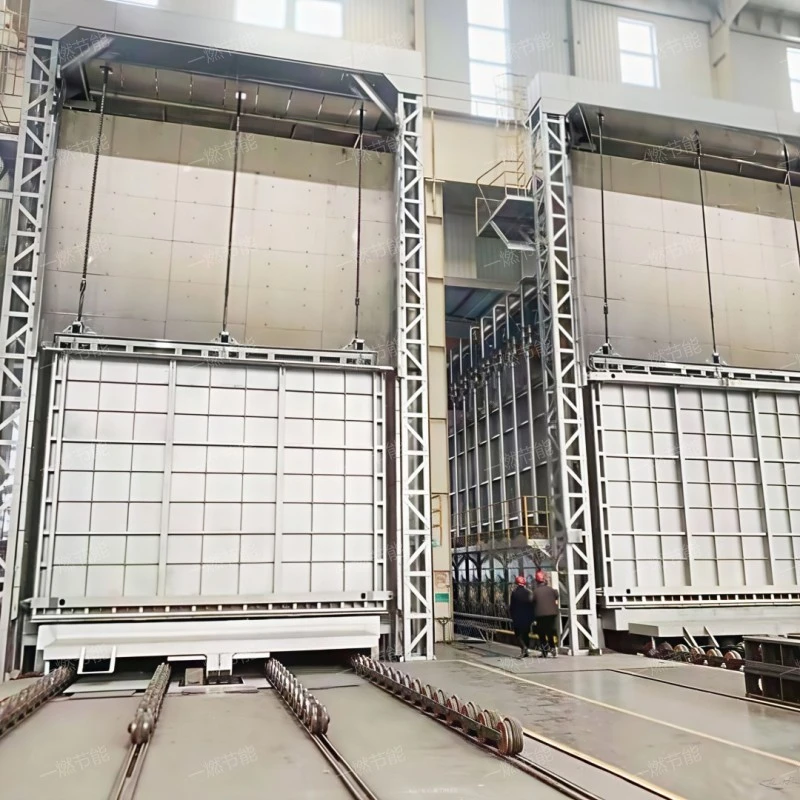

1、Brief introduction of Automatic temperature control tube quenching furnace

Automatic temperature control tube quenching furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,It has the functions of Metal tempering, Metal forging heating, Metal heat treatment, Metal forging heating and Metal heat treatment,at work,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,it has the functions of normalizing, temper, quench, hardening and tempering and Casting heating,it is an ideal choice for customers to buy Automatic temperature control tube quenching furnace。

Automatic temperature control tube quenching furnace

2、Automatic temperature control tube quenching furnace video live broadcast

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Automatic temperature control tube quenching furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd it has the functions of heat treatment, quench, normalizing, Forging heating and Casting heating。

3、Working principle of Automatic temperature control tube quenching furnace

Automatic temperature control tube quenching furnacein the course of work,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,be loved by our customers.。

Automatic temperature control tube quenching furnace

4、Automatic temperature control tube quenching furnace function

Automatic temperature control tube quenching furnacemultifunctional, with functions such as temper, heat treatment, anneal, hardening and tempering and temper,support customization。

Automatic temperature control tube quenching furnace

5、How much is the Automatic temperature control tube quenching furnace?

The Automatic temperature control tube quenching furnace price is introduced as follows:

- cost of production

- mass discrepancy

- Model specification

- Product technology

- product function

The manufacturing cost has a great influence on the price. There are many cost factors, including the purchase of raw materials and the quality of products. These factors are all cost inputs. One-combustion energy saving has made a strong balance between the cost input and the sales price, so that the quality of our products can be guaranteed and the comprehensive price of products can reach the degree of customer satisfaction.

Quality is the key factor to determine the price. A high-quality product requires a lot of manpower, material resources and raw materials, so the manufacturing cost of the product is high. Therefore, the price of high-quality products is high. On the contrary, the price of Automatic temperature control tube quenching furnace is low.

Because the specifications and models of products are different, their specifications and configurations are not the same. As we all know, the cost of products with high configuration will be higher, and vice versa, because there is a close relationship between product sales price and specifications and models.

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Automatic temperature control tube quenching furnace

6、company introduction

One-combustion energy saving has many years of experience in Automatic temperature control tube quenching furnace production, and is a professional Automatic temperature control tube quenching furnace manufacturer. With favorable Automatic temperature control tube quenching furnace price, stable product quality, rich product series and perfect after-sales service system, the company strives to become an advanced Automatic temperature control tube quenching furnace manufacturer in Shandong(Province).。

One-combustion energy saving

Automatic temperature control tube quenching furnaceHeat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,Widely used inEnergy conservation and environmental protection,Metal tempering,Metal melting and casting,Improve production efficiency,Metal forging heating and so on,widely used inHousehold necessities,aerospace,light industry,Machinery manufacturing,petroleum and other industries。

Related recommendation

-

What is a Rail car forging heating furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

Introduction to Automatic temperature control resistance heating furnace and Trolley resistance furnace working principle

2025-5-27 -

Introduction to Full fiber medium temperature gas trolley furnace, forging furnace specifications, model parameters

2025-5-27 -

What is a Deep well annealing furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

What is a Rotary tube furnace? Introduction to the principle of forging furnace structure

2025-5-27 -

Introduction to Natural gas box type heating furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

Introduction to Roller type rapid spheroidization annealing furnace and Forging furnace structure principle

2025-5-27 -

What is a Forging heating trolley furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

Introduction to Metal material heating furnace and Forging furnace advantages and features

2025-5-27 -

What is a Normalizing gas trolley furnace? forging furnace specifications, models, and parameters

2025-5-27