Introduction to Circular tube continuous annealing furnace and forging furnace structure principle

Circular tube continuous annealing furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,the principle is simple.The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,Commonly used inMetal heat treatment,Energy conservation and environmental protection,Improve production efficiency,Metal tempering,Metal melting and casting and so on,the product looks beautiful.,Cheap and high quality。The following is to introduce the Circular tube continuous annealing furnace:

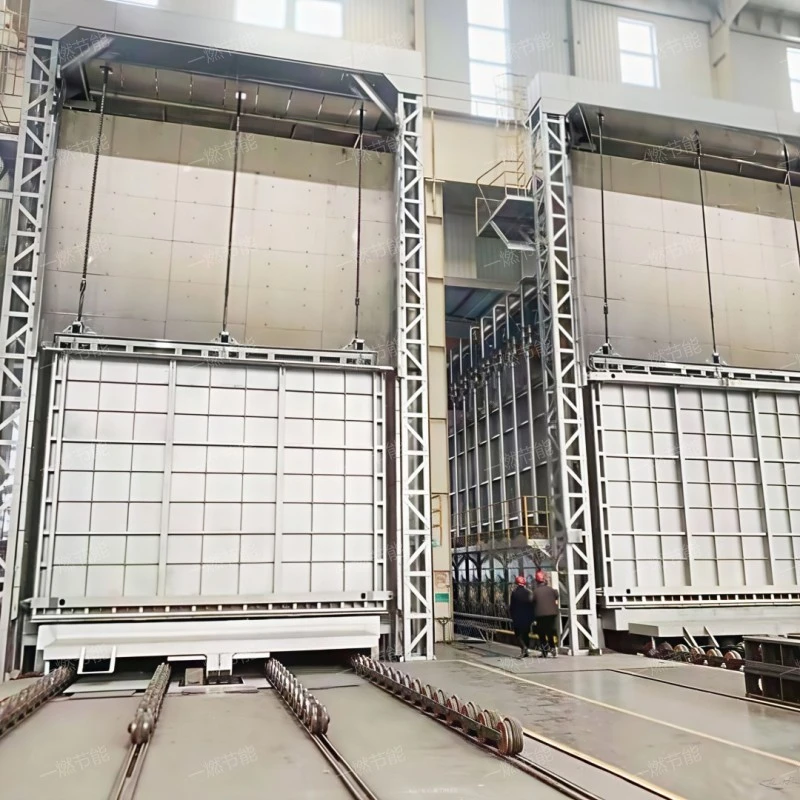

1、Brief introduction of Circular tube continuous annealing furnace

Circular tube continuous annealing furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,it is an ideal choice for customers to buy Circular tube continuous annealing furnace。

Circular tube continuous annealing furnace

2、Circular tube continuous annealing furnace structure

The Circular tube continuous annealing furnace structure is introduced as follows:

- convection chamber

- combustor

- furnace chamber

- Radiation chamber

- Waste heat recovery system

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

A space for holding metallic materials for heating.

The heat load of the main place for Circular tube continuous annealing furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Used to recover the exhaust heat of the heating furnace. There are two kinds of recovery methods, one is to recover by preheating combustion air, so that the recovered heat can return to the furnace again; The other is to use another recovery system to recover heat. The former is called air preheating mode, and the latter is usually called waste heat boiler mode.

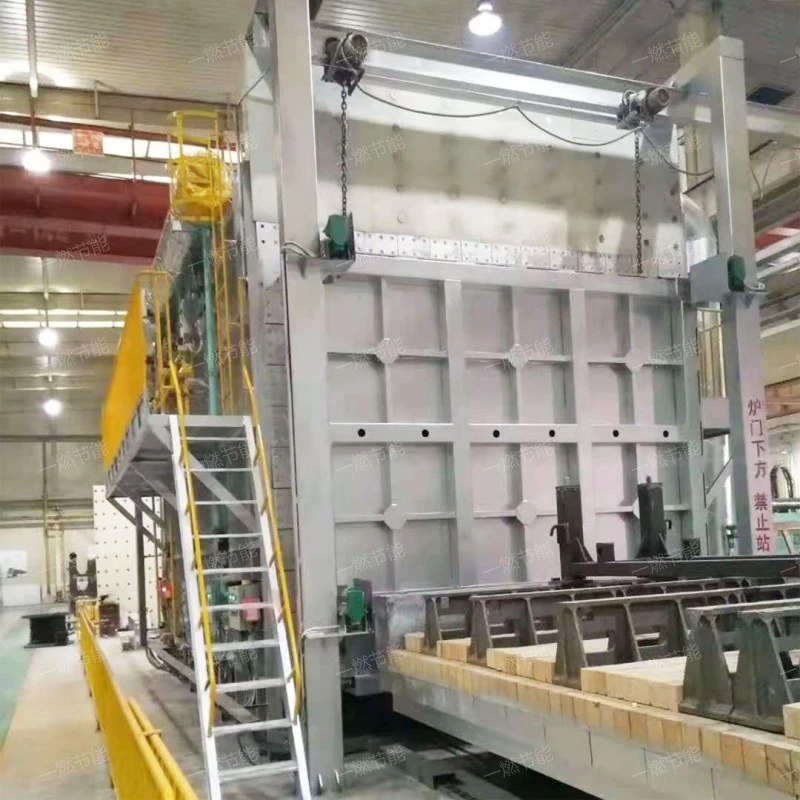

Circular tube continuous annealing furnace

3、Circular tube continuous annealing furnace characteristics

The Circular tube continuous annealing furnace features are as follows:

- Easy to control

- energy saving and environmental protection

- Efficient heating

- Stable and reliable

- Strong adaptability

The combustion system and ventilation system of the Circular tube continuous annealing furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

Natural gas is a kind of clean energy, which produces less waste gas and waste smoke after combustion and has little environmental pollution. At the same time, through wall regenerative combustion technology, flue gas waste heat recovery system and other technical means, the Circular tube continuous annealing furnace further improves energy utilization efficiency and reduces energy consumption and emissions.

The Circular tube continuous annealing furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

The Circular tube continuous annealing furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The Circular tube continuous annealing furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

Circular tube continuous annealing furnace

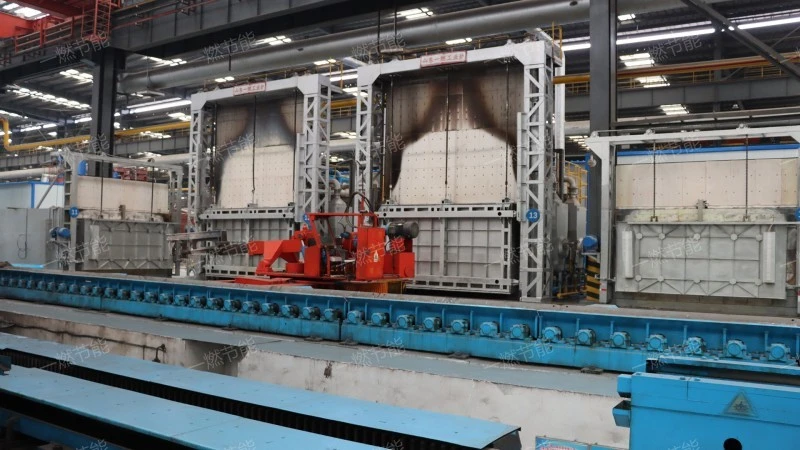

4、Circular tube continuous annealing furnace working site

You can buy Circular tube continuous annealing furnace according to your needs and show you product videos.。

Circular tube continuous annealing furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd it has been widely used in war industry, pharmacy, aerospace, petroleum, heat treatment and other industries。

5、How much is the Circular tube continuous annealing furnace?

The Circular tube continuous annealing furnace price is introduced as follows:

- product function

- technology content

- region

- Cost input

- brand

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

The price of Circular tube continuous annealing furnace in Jinan, Shandong province is much lower than that in other regions, and One-combustion energy saving is a self-produced and self-selling manufacturer not only pays attention to the quality of products, but also pays more attention to customer satisfaction, and always adopts the marketing strategy of small profits but quick turnover to make the Circular tube continuous annealing furnace price positioning more reasonable, low-cost and economical.

Product manufacturers are different, and the cost spent by each manufacturer in producing products is definitely different. The higher the cost of producing products, the higher the price of products set by manufacturers. On the contrary, the Circular tube continuous annealing furnace price is low.

Different brands of products in the same series have more or less differences in product prices, and different brands of Circular tube continuous annealing furnace have more or less differences in price.

Circular tube continuous annealing furnace

6、One-combustion energy saving's after-sales service

Our company will not only provide customers with excellent quality Circular tube continuous annealing furnace, but also choose a series of high-quality services such as appropriate specifications and models according to their actual needs.。

One-combustion energy saving

Circular tube continuous annealing furnaceis a kind of high quality and low price Circular tube continuous annealing furnace,it is mainly composed of combustor, Radiation chamber, ventilation system, convection chamber and ventilation system,energy saving and environmental protection,Easy to maintain,Strong adaptability,Stable and reliable,Easy to control。

Related recommendation

-

What is a Low temperature annealing furnace for trolley? Introduction to the advantages and characteristics of the Forging furnace

2025-5-27 -

Introduction to Double beam walking back and forth furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

Introduction to Dual car strip annealing furnace, Forging furnace specifications, model parameters

2025-5-27 -

Introduction to Car type continuous annealing furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Tempered gas trolley furnace and heating furnace working principle

2025-5-27 -

What is a Chain type iron core annealing furnace? heating furnace specifications, models, and parameters

2025-5-27 -

Introduction to High temperature rapid quenching furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

What is a Chain track quenching furnace? How much is the price of the heating furnace?

2025-5-27 -

What is a SCR low-temperature catalyst flue gas denitrification system? Introduction to the principle of SCR denitration structure

2025-5-27 -

Introduction to Continuous gas trolley furnace, forging furnace advantages, characteristics and principles

2025-5-27