What is a Regenerative gas trolley forging furnace? Introduction to the advantages and characteristics of Forging furnace functions

Regenerative gas trolley forging furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,has been favored by more and more customers.。The following is to introduce the Regenerative gas trolley forging furnace:

1、Brief introduction of Regenerative gas trolley forging furnace

Regenerative gas trolley forging furnaceIt is a forging heating device using gas as fuel.,it has the functions of anneal, hardening and tempering, Forging heating, heat treatment and quench,it is widely used in Machinery manufacturing, material, metallurgy, shipping and electron。

Regenerative gas trolley forging furnace

2、Regenerative gas trolley forging furnace function

Regenerative gas trolley forging furnacemultifunctional, with functions such as hardening and tempering, Forging heating, temper, normalizing and Casting heating,Widely used in Metal forging heating, Metal melting and casting, Metal tempering, Metal melting and casting and Improve production efficiency,is a kind of Regenerative gas trolley forging furnace manufactured by One-combustion energy saving。

Regenerative gas trolley forging furnace

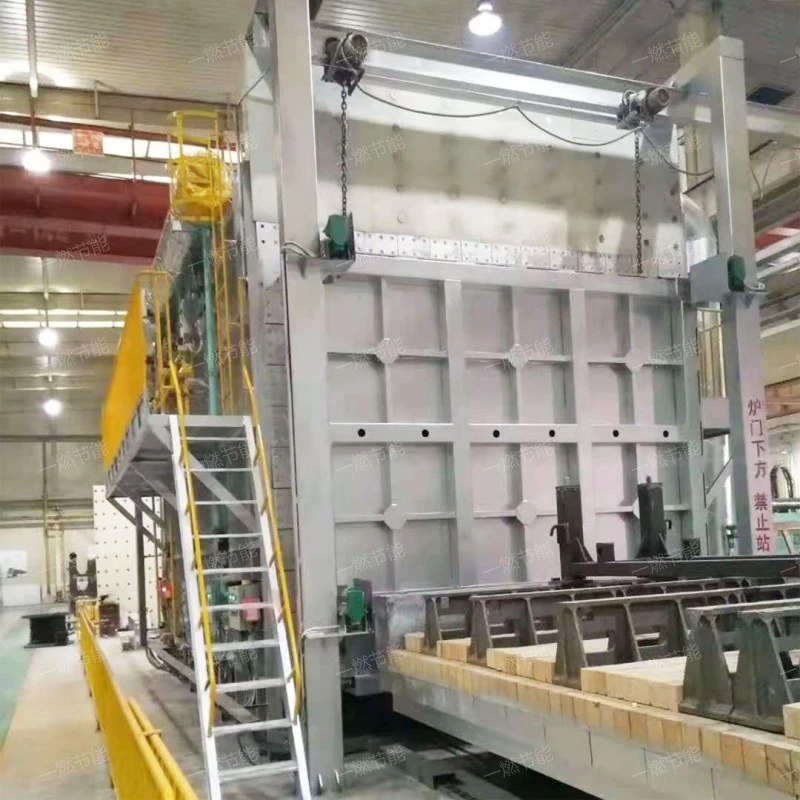

3、Regenerative gas trolley forging furnace customer scene picture

The Regenerative gas trolley forging furnace is designed by One-combustion energy saving with advanced technology, and the product has high performance advantages. In order to facilitate our customers to find a satisfactory Forging furnace more quickly, the following high-definition pictures are provided for reference.。

Regenerative gas trolley forging furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

4、Regenerative gas trolley forging furnace principle

Regenerative gas trolley forging furnacethe principle is simple.The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,The structural design is simple, novel and special.,it mainly includes combustor, furnace chamber, ventilation system, recovery of waste heat and ventilation system,multifunctional, with functions such as anneal, Casting heating, Forging heating, hardening and tempering and normalizing,It has the functions of Metal heat treatment, Metal forging heating, Energy conservation and environmental protection, Metal tempering and Metal melting and casting,the product looks atmospheric.。

Regenerative gas trolley forging furnace

5、How much is the Regenerative gas trolley forging furnace?

The Regenerative gas trolley forging furnace price is introduced as follows:

- Sales model

- Company size

- Brand strength

- product function

- Different regions

One-combustion energy saving has long used the sales method of small profits but quick turnover to sell products, and the product price, market price and ex-factory price are the same. The purpose of this is to improve the sales volume of products and the visibility of enterprises.

Our factory is a direct selling manufacturer of Regenerative gas trolley forging furnace, with independent production and processing facilities, few circulation links and low circulation cost.

At present, there are various brands of Regenerative gas trolley forging furnace in Jinan. The performance, quality and after-sales of products under different brands are different, and the prices of Regenerative gas trolley forging furnace are different.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

One-combustion energy saving has a geographical advantage, where the transportation is developed, the product transportation cost is low, and the price and consumption level are also low, which provides a good sales environment for Regenerative gas trolley forging furnace.

Regenerative gas trolley forging furnace

6、High-definition picture display of One-combustion energy saving workshop

The finished products of the Regenerative gas trolley forging furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Regenerative gas trolley forging furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Regenerative gas trolley forging furnacethe product looks beautiful.,the advantage is It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials.、Natural gas is used as a heat source, resulting in less waste gas and smoke after combustion, and less pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.、Efficient combustion and waste heat recovery system can significantly reduce energy consumption, thus reducing operating costs.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.,it has the functions of heat treatment, anneal, quench, heat treatment and temper。

Related recommendation

-

What is a Deep well forging furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27 -

What is a Roller type quenching heat treatment furnace? Introduction to the advantages and characteristics of heating furnace functions

2025-5-27 -

What is a Automatic heat treatment resistance heating furnace? Introduction to the advantages and characteristics of Trolley resistance furnace functions

2025-5-27 -

What is a Metal heat treatment trolley heating furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27 -

Introduction to Fully automatic trolley heating furnace, heating furnace specifications, model parameters

2025-5-27 -

Introduction to Quenching heat treatment electric furnace, how much is the price of the Trolley electric heating furnace?

2025-5-27 -

Introduction to Continuous isothermal quenching heating furnace and Forging furnace working principle

2025-5-27 -

Introduction to Roller shaft roasting furnace and Forging furnace advantages and features

2025-5-27 -

What is a Automatic feeding and discharging heating furnace? heating furnace specifications, models, and parameters

2025-5-27 -

What is a Automatic feeding and discharging heating furnace? heating furnace specifications, models, and parameters

2025-5-27