Introduction to Resistance heating continuous annealing furnace, advantages, characteristics and principles of Trolley resistance heating furnace

Resistance heating continuous annealing furnaceis an industrial equipment that uses electric current to generate heat through a resistor to heat materials.,the product looks atmospheric.。The following is to introduce the Resistance heating continuous annealing furnace:

1、Brief introduction of Resistance heating continuous annealing furnace

Resistance heating continuous annealing furnaceis an industrial furnace that uses electric current to generate heat through a resistor, and is mainly used for heating, heat treating or melting metals, nonmetals and other materials.,has been favored by more and more customers.。

Resistance heating continuous annealing furnace

2、Resistance heating continuous annealing furnace explanation video

The following is the live video of Resistance heating continuous annealing furnace designed and produced by One-combustion energy saving for users, from which we can see the The temperature control precision is high, and the Resistance heating continuous annealing furnace is equipped with advanced temperature control system, which can accurately control the temperature in the furnace and ensure the stability and reliability of the process.、Long service life. The main parts of the Resistance heating continuous annealing furnace, such as electric heating elements and furnace, are made of high-quality materials, which have high durability and stability and long service life.、The safety is high, and the Resistance heating continuous annealing furnace is electrically controlled, which has higher safety than the fuel stove and can effectively avoid potential safety hazards such as fire and explosion.、Easy to control, accurate temperature control, and easy to realize automatic control.、Strong customization, the Resistance heating continuous annealing furnace can be customized according to the actual needs of users, such as heating power, furnace size, temperature control accuracy, etc., to meet the requirements of specific processes. of Resistance heating continuous annealing furnace.。

Resistance heating continuous annealing furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd usually used in building materials, metallurgy, electron, Special material, glass and other fields。

3、Structural characteristics of Resistance heating continuous annealing furnace

The Resistance heating continuous annealing furnace structure is introduced as follows:

- grate

- base

- eye split

- heating element

- furnace chamber

Used to place the workpiece or material to be heated, which is convenient for operators to take and put.

Used to support the whole Resistance heating continuous annealing furnace and ensure its stability.

It is arranged on the furnace body and used to observe the heating situation in the furnace.

Electric heating elements (such as Fe-Cr-Al electric heater, Ni-Cr electric heater, silicon carbide rod, etc.) are the core components for generating heat.

Refractory materials are built in the furnace to withstand high temperature.

Resistance heating continuous annealing furnace

4、Resistance heating continuous annealing furnace use

The purpose of Resistance heating continuous annealing furnace is introduced as follows:

- powder metallurgy

- Ceramic and glass industries

- Metal melting and casting

- Metal heat treatment

- New material development

Used for sintering and heat treatment of powder.

Used for baking and annealing of ceramics and glass.

Used for melting low melting point metals and alloys.

Such as quenching, normalizing, annealing, tempering, etc.

Used for synthesis and heat treatment of special materials and new materials.

Resistance heating continuous annealing furnace

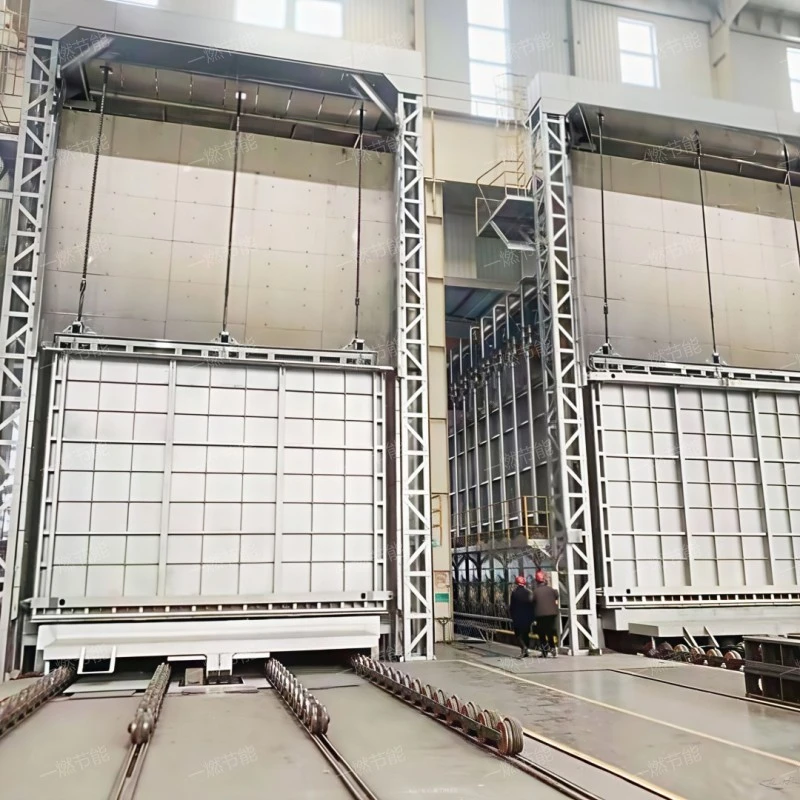

5、Resistance heating continuous annealing furnace work site real shot

Excellent materials, atmospheric design, fine workmanship, impeccable, trustworthy, all-round high-definition shooting, which is helpful for customers' reference.。

Resistance heating continuous annealing furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

Resistance heating continuous annealing furnaceit has the characteristics of Fast heating speed, Environmental protection and safety, Strong adaptability, High thermal efficiency and High flexibility,the product looks beautiful.,Widely used in hardening and tempering, normalizing, Metal heat treatment heating, Roasting and annealing of glass ceramics and Powder metallurgy sintering。

Related recommendation

-

Introduction to SCR flue gas catalytic denitrification, advantages, characteristics and principles of SCR denitration

2025-5-27 -

Introduction to Double trolley steel pipe annealing furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Full fiber trolley forging heating furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Energy saving and environmentally friendly trolley heating furnace and forging furnace working principle

2025-5-27 -

Introduction to Gas powered trolley heating furnace and heating furnace advantages and features

2025-5-27 -

Introduction to Automatic temperature regulating tube furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

What is a Heat treatment tube quenching furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

Introduction to Heating furnace flue gas denitrification system, SCR denitration system specifications, model parameters

2025-5-27 -

Introduction to High temperature chain heating furnace and Forging furnace advantages and features

2025-5-27 -

Introduction to Continuous carburizing heat treatment industrial furnace, Forging furnace advantages, characteristics and principles

2025-5-27